In 1997, Professor Wang Xibin of Beijing University of technology conducted an experimental study on the grinding surface residual stress of several common structural ceramics by using X-ray diffraction method, and pointed out the residual stress of the grinding surface of bevel gear steel σ From the original stress of blank surface layer σ 0 and residual stress during grinding Δσ It consists of two parts, namely:

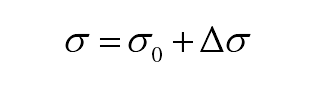

Therefore, the residual stress in grinding process caused by grinding of bevel gear steel is studied Δσ The original state of the sample without grinding shall be measured first σ 0 In order to study the variation law of residual stress in grinding surface, X-ray diffraction combined with electrolytic stripping polishing was used. XF-1 electrolytic polishing machine is used in the test. The electrolyte used for 30CrMnTi material is saturated sodium chloride solution. The electrolytic voltage is about 15 V and the current is about 2.5 a. The height change of bevel gear steel corrosion area before and after corrosion is accurately measured by micrometer, and the stripping depth is obtained. In the test, the X-ray stress analyzer is used to measure the surface residual stress every 0.05 mm of corrosion (about 1 min of electrolysis time). During the measurement, the diffraction angle is strictly ensured to be perpendicular to the grinding direction. The original state of the sample without bevel gear steel grinding σ 0 changes along the layer depth, and the results are shown in Figure 1.

It can be seen from Figure 1 that the carburized layer area of bevel gear steel shows residual compressive stress. The residual stress value on the surface is about – 225 MPa, and the maximum value of residual compressive stress is obtained at the depth of about 0.4 mm-0.5 mm, which is about – 360 MPa. The value of residual compressive stress decreases gradually along the layer depth, and the residual stress changes from compressive stress to tensile stress when it reaches the transition layer area from carburized layer to center. This is because the residual stress on the surface of bevel gear steel is mainly the comprehensive result of the superposition of microstructure stress and thermal stress, and the stress change caused by microstructure transformation plays a leading role. After carburizing and quenching, the surface layer is high-carbon martensite and the core is low-carbon martensite. The specific volume of the former is larger than that of the latter, so the volume expansion of the surface layer is larger after the quenching process, while the volume expansion of the low-carbon martensite in the core is smaller. The core restricts the free expansion of the surface layer, resulting in the stress state of compression of the surface layer and tension of the core.

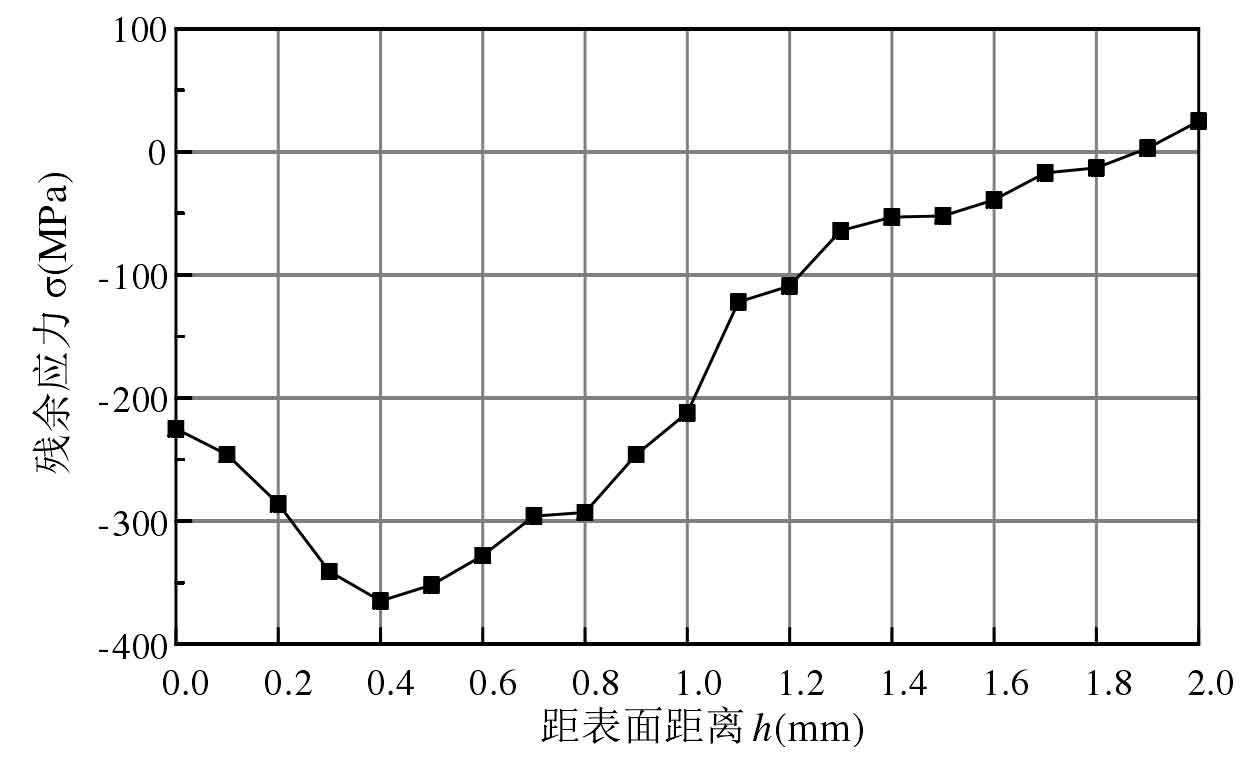

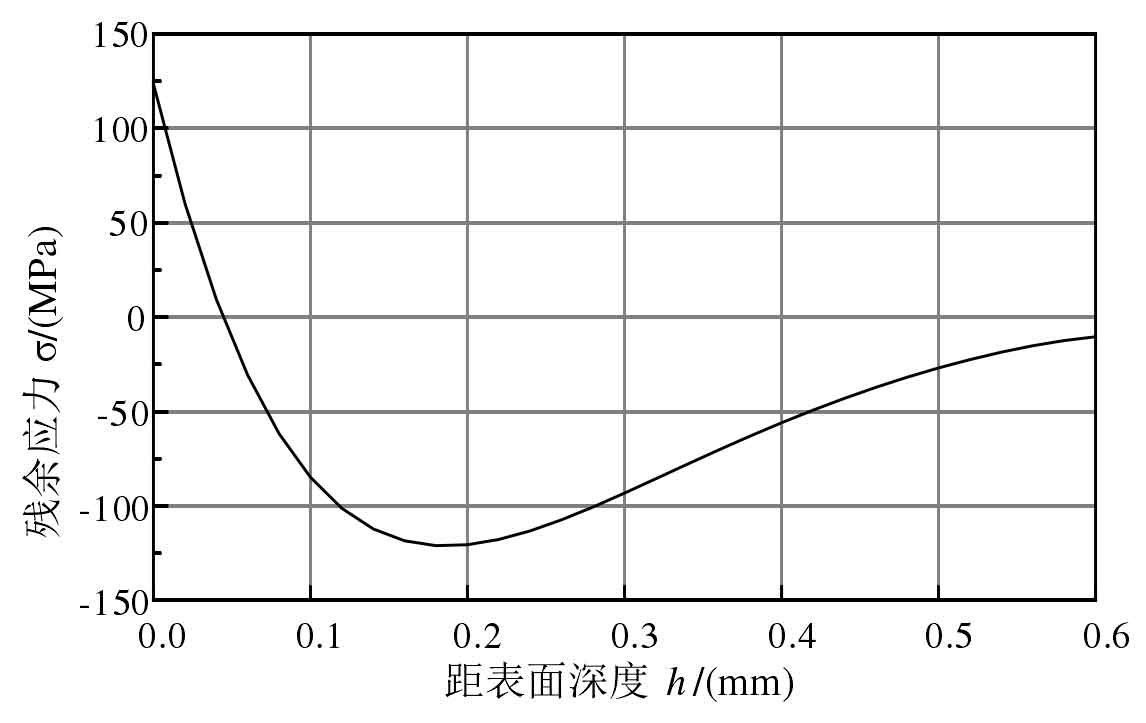

Then, the influence of bevel gear steel grinding on the surface residual stress is studied. The grinding speed vs = 20.3 M / s and grinding depth AP = 50 μ m. The residual stress of the surface layer after grinding is measured with the bevel gear steel with the speed VW = 1200 mm / min as the standard σ As shown in Figure 2.

It can be seen from Figure 2 that the change of residual stress layer after grinding of bevel gear steel comes from the residual stress caused by the grinding process itself on the one hand, and from the pre grinding and actual grinding process of bevel gear steel during grinding, which reduces the retention degree of compressive stress layer of bevel gear steel. The final residual stress on the surface after grinding is the result of the combined action of the two.

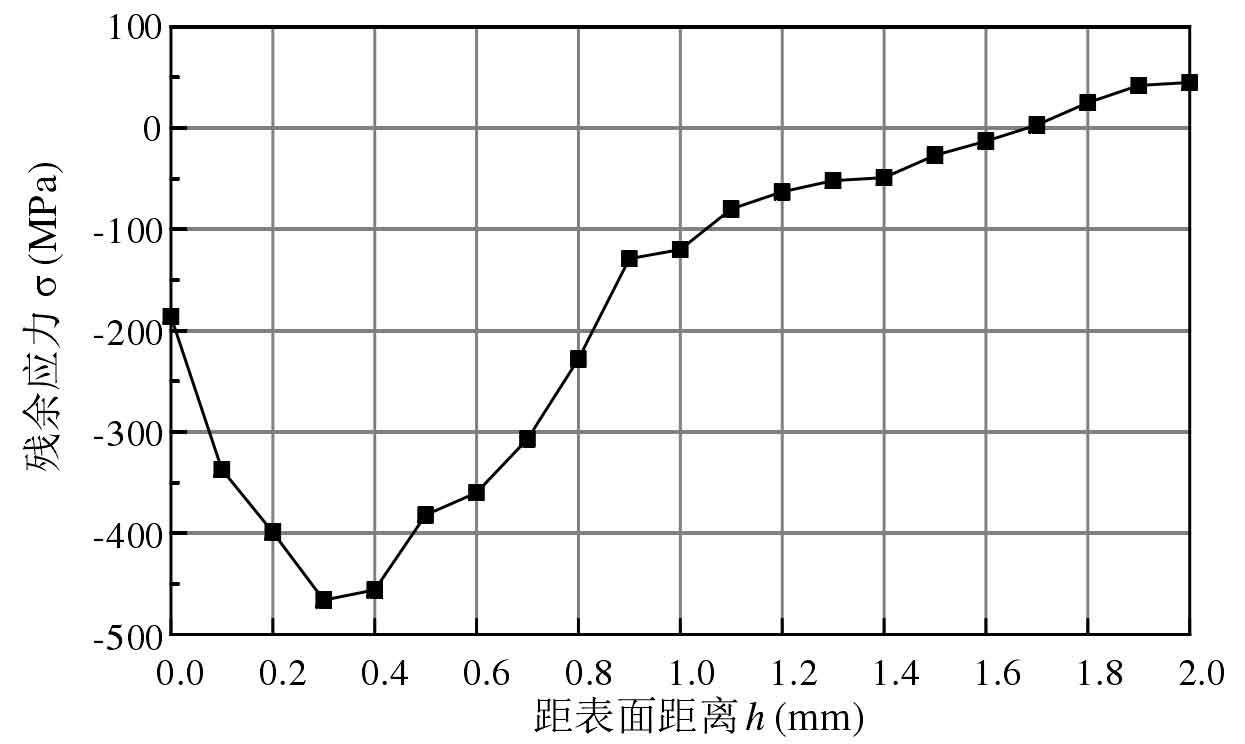

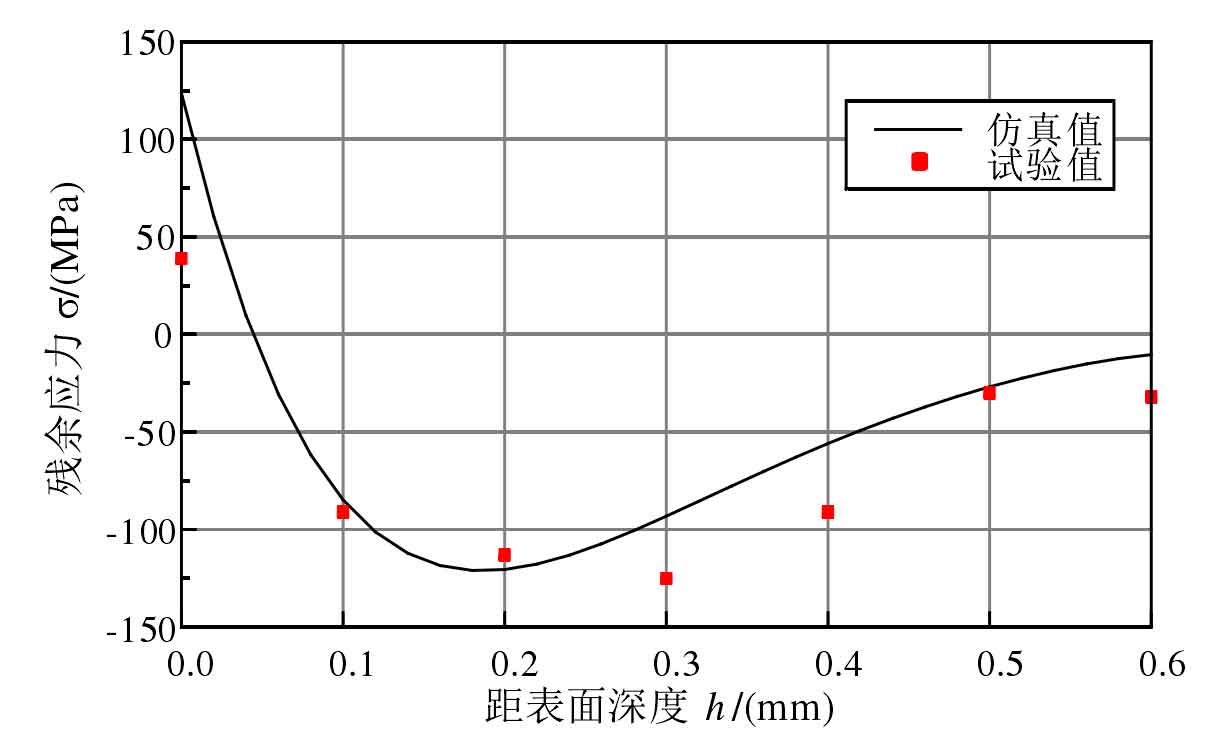

According to the actual processing situation, the grinding removal layer depth of bevel gear steel is about 0.2 mm. Considering the residual stress layer removed in the grinding process, according to σ=σ 0+ Δσ The residual stress in grinding process is calculated Δσ, The specific operation principle is shown in Figure 3. Then the calculated residual stress of grinding process Δσ Compared with the simulation data in Fig. 4, the results are shown in Fig. 5.

It can be seen from Figure 5 that the results of ANSYS simulation can reflect the basic change trend of the test results to a certain extent. Therefore, the comparison between the simulation and the test results verifies the effectiveness of the residual stress simulation of 30CrMnTi material grinding surface based on the principle of mechanical thermal coupling by ANSYS.