1. Introduction

Hypoid gears play a crucial role in modern mechanical systems, especially in applications that require the transmission of motion between non – parallel and non – intersecting axes. Their unique design offers several advantages, such as high load – carrying capacity, smooth operation, and compact size. These gears are widely used in the automotive industry, for example, in differential drives, and in aerospace applications where reliability and performance are of utmost importance.

However, the machining process of hypoid gears is complex, involving multiple adjustable parameters on the machine tool. These parameters significantly influence the meshing performance of the gear pair, which in turn affects the service life and noise level of the mechanical system. Therefore, understanding the relationship between machine tool adjustment parameters and the meshing performance of hypoid gears is essential for improving gear manufacturing quality and optimizing the performance of mechanical products.

In recent years, many researchers have focused on the study of hypoid gear meshing performance. Some studies have explored the contact characteristics and loading tooth surface contact analysis. Others have used methods like tooth contact analysis (TCA), tooth surface load – carrying contact analysis, and finite element methods to analyze the meshing morphology, tooth surface contact stress, and tooth root stress of hypoid gear pairs. However, the research on the impact of machine tool parameters is relatively limited. This paper aims to fill this gap by comprehensively studying the influence of machine tool adjustment parameters on the meshing performance of hypoid gears.

2. Mathematical Models of Hypoid Gear Tooth Surfaces

2.1 Establishment of the Small – Wheel Tooth Surface Machining Coordinate System

The small – wheel tooth surface machining coordinate system is a fundamental framework for understanding the machining process of hypoid gears. As shown in Figure 1, there are several coordinate systems involved: \(S_{ml}\), \(S_{e}\), \(S_{d}\) are fixed to the machine tool, and \(S_{p}\) is fixed to the cutter head and rotates around the axis \(z_{p}\).

When the small gear is cut by the double – helix method, the carriage rotates around the axis \(Z_{ml}\) and moves along the axis \(Z_{ml}\) simultaneously. At the same time, the small gear rotates around the axis \(x_{d}\). Through this generating motion, the tooth surface of the small gear is formed as the envelope of the cutter surface family. The machine tool adjustment parameters \(q_{1}\), \(S_{r1}\), x1, \(H_{1}\), etc., which include angular cutter position, radial cutter position, cutter inclination angle, cutter rotation angle, vertical wheel position, bed position, machine tool installation angle, axial wheel position, and spiral motion coefficient, play key roles in determining the shape of the tooth surface.

[Insert Figure 1: Small – wheel tooth surface machining coordinate system]

2.2 Tooth Surface Equation of the Small Gear

In the \(S_{p}\) coordinate system, the vector of the cutting cone formed by the cutter line can be expressed as: \(r_{p}=\left[\begin{array}{c}\left(r_{g1}+u_{1}\sin\alpha_{1}\right)\cos\beta_{1}\\\left(r_{g1}+u_{1}\sin\alpha_{1}\right)\sin\beta_{1}\\-u_{1}\cos\alpha_{1}\\1\end{array}\right]\) And its unit normal vector \(n_{p}\) is: \(n_{p}=\left[\begin{array}{c}\cos\alpha_{1}\cos\beta_{1}\\\cos\alpha_{1}\sin\beta_{1}\\\sin\alpha_{1}\end{array}\right]\)

By rotating \(r_{p}\) and \(n_{p}\) to the \(S_{1}\) coordinate system according to the small – wheel tooth surface machining coordinate system, the tooth surface equation \(r_{1}\) of the small gear in the \(S_{1}\) coordinate system and its unit normal vector \(n_{1}\) can be obtained as follows: \(\left\{\begin{array}{l}r_{1}\left(u_{1},\beta_{1},\varphi\right)=M_{1p}r_{p}\left(u_{1},\beta_{1}\right)\\n_{1}\left(u_{1},\beta_{1},\varphi\right)=L_{1p}n_{p}\left(u_{1},\beta_{1}\right)\\f_{1}\left(u_{1},\beta_{1},\varphi\right)=n_{1}\cdot\left(\frac{\partial r_{1}(1:3)}{\partial\varphi}\right)\end{array}\right.\) where \(f_{1}\) is the meshing equation when generating the small gear, \(M_{1p}\) represents the transformation matrix from the \(S_{p}\) coordinate system to the \(S_{1}\) coordinate system, and \(L_{1p}\) is the third – order sub – matrix of \(M_{1p}\).

2.3 Influence of Machine Tool Adjustment Parameter Errors on the Tooth Surface Equation

In actual machining, there are often errors in machine tool adjustment parameters. Let X be the actual machine tool adjustment parameter, \(X’\) be the theoretical machine tool adjustment parameter, and \(\Delta X\) be the machine tool adjustment parameter error. Then \(X = X’+\Delta X\).

Substituting this into the tooth surface equation, we can get the tooth surface equation with machine tool parameter errors: \(r_{1}=r_{1}\left(\mu_{1},\theta_{1},\varphi,X’\right)\). This equation reflects how parameter errors affect the shape of the tooth surface, which is crucial for analyzing the meshing performance of hypoid gears.

3. TCA Mathematical Model

3.1 Tooth Surface Equation of the Large Gear

The large gear of hypoid gears is usually processed by the forming method. According to relevant literature, its theoretical tooth surface equation is: \(\left\{\begin{array}{l}r_{2}=r_{2}\left(\mu_{2},\theta_{2}\right)\\n_{2}=n_{2}\left(\theta_{2}\right)\end{array}\right.\)

3.2 Meshing Coordinate System of the Gear Pair

The meshing coordinate system of the gear pair is shown in Figure 2. \(S_{e}{x_{e},y_{e},z_{e}}\) is the auxiliary coordinate system of the large gear, \(S_{1}{x_{h},y_{h},z_{h}}\) is the fixed coordinate system for the assembly of the large and small gears, \(S_{1}{x_{1},y_{1},z_{1}}\) is the moving coordinate system fixed to the small gear and rotates around the axis \(x_{1}\), and \(S_{2}{x_{2},y_{2},z_{2}}\) is the moving coordinate system fixed to the large gear and rotates around the axis \(x_{0}\). E is the offset distance of the small gear. After the large and small gears are assembled, they need to rotate a certain angle to reach the meshing position, where \(\varphi_{1}\) and \(\varphi_{2}\) are the rotation angles of the small gear and the large gear respectively.

[Insert Figure 2: Meshing coordinate system]

3.3 Determination of the Contact Trajectory and Transmission Error

According to the gear meshing principle, \(r_{h1}\), \(r_{h2}\), \(n_{h1}\), \(n_{h2}\) satisfy the following equations: \(\left\{\begin{array}{l}r_{h1}\left(u_{1},\theta_{1},\varphi,\varphi_{1},X’\right)=r_{h2}\left(u_{2},\theta_{2},\varphi_{2},E\right)\\n_{h1}\left(\theta_{1},\varphi,\varphi_{1},X’\right)=n_{h2}\left(\theta_{2},\varphi_{2},E\right)\\f\left(u_{1},\theta_{1},\varphi\right)=n_{1}\cdot v_{1}=0\end{array}\right.\)

This system of equations contains 7 unknowns (\(\mu_{1}\), \(\varphi_{1}\), \(\theta_{1}\), \(\varphi\), \(\mu_{2}\), \(\theta_{2}\), \(\varphi_{2}\)) and 6 independent scalar equations. By giving a value to one variable and initial values to the other 6 parameters, a set of tooth surface parameters can be solved. By changing the value of the given variable, a series of tooth surface parameters can be obtained. Substituting these parameters into the large – gear tooth surface equation, a series of points on the large – gear tooth surface can be obtained, and the connection of these points is the contact trajectory line on the large – gear tooth surface.

Based on this, the contact area on the large – gear tooth surface can be obtained according to the curvature relationship between conjugate tooth surfaces, and the transmission error curve can be obtained according to the definition of transmission error. The following table summarizes the main steps of obtaining the contact trajectory and transmission error:

| Step | Description |

|---|---|

| 1 | Set up the equations based on gear meshing principle |

| 2 | Assign values to variables and solve for tooth surface parameters |

| 3 | Substitute parameters into large – gear tooth surface equation to get contact trajectory points |

| 4 | Calculate contact area using curvature relationship |

| 5 | Obtain transmission error curve according to definition |

4. Influence of Machine Tool Adjustment Parameters on Contact Trajectory and Transmission Error

4.1 Gear Pair Parameters

In this study, a specific hypoid gear pair is selected, and its wheel blank parameters and machining parameters are shown in Table 1 and Table 2.

| Table 1: Basic Parameters of Hypoid Gear Wheel Blanks | ||

|---|---|---|

| Parameter | Small Wheel | Large Wheel |

| Number of Teeth | 7 | 43 |

| Outer End Diameter of Pitch Cone /mm | 150.1349 | 150.3843 |

| Average Pressure Angle / (°) | – | – |

| Offset Distance /mm | – | – |

| Tooth Width /mm | 43.7299 | 40 |

| Shaft Intersection Angle / (°) | – | – |

| Helix Angle / (°) | 45 | 33.45 |

| Face Cone Angle / (°) | 11 | 78.46 |

| Pitch Cone Angle / (°) | 14.44 | 79.21 |

| Root Cone Angle / (°) | 10.26 | 75 |

| Hand of Helix | Left | Right |

| Table 2: Machine Tool Machining Adjustment Parameters of Hypoid Gears | ||

|---|---|---|

| Parameter | Small Wheel | Large Wheel |

| Cutter Head Tooth Profile Angle / (°) | 20 | 30 |

| Tool Tip Radius /mm | 114.8409 | 116.1 |

| Vertical Wheel Position /mm | 27.3700 | 111.0757 |

| Radial Wheel Position /mm | 117.1353 | 0 |

| Axial Wheel Position /mm | 0.0730 | 9.6518 |

| Angular Cutter Position / (°) | 65.6224 | 0 |

| Cutter Inclination Angle / (°) | 16.3882 | 0 |

| Cutter Rotation Angle / (°) | – 25.6862 | 0 |

| Wheel Blank Installation Angle / (°) | – 6.4576 | 70.2509 |

| Rolling Ratio | 6.0615 | 0 |

| Bed Position /mm | 14.6514 | 0 |

| Spiral Motion Coefficient / (mm·rad⁻¹) | 7.1860 | 0 |

4.2 Analysis of Displacement – Type Machine Tool Adjustment Parameter Errors

Displacement – type machine tool adjustment parameters include vertical wheel position, bed position, axial wheel position, and radial cutter position. The influence of these parameters on the tooth surface contact area is analyzed as follows:

- Vertical Wheel Position: A positive change in the vertical wheel position causes the contact trajectory of the working – surface tooth to move towards the large end of the tooth surface, while a negative change causes it to move towards the small end. The change trend of the non – working surface is opposite to that of the working surface.

- Axial Wheel Position: A positive change in the axial wheel position causes the contact trajectories of the two tooth surfaces of the large gear to move towards the large end of the tooth surface, and a negative change causes them to move towards the small end.

- Bed Position: A positive change in the bed position causes the contact trajectories of the two tooth surfaces of the large gear to move towards the small end of the tooth surface, and a negative change causes them to move towards the large end.

- Radial Cutter Position: On the working surface, a positive change in the radial cutter position causes the contact trajectory to move towards the small end of the tooth surface, and a negative change causes it to move towards the large end. On the non – working surface, a positive change causes the contact trajectory to move towards the large end and the tooth tip, and a negative change causes it to move towards the small end and the tooth root. Excessive radial cutter position error may cause edge contact at the tooth tip and tooth root.

The influence of displacement – type machine tool adjustment parameters on the contact trajectory and transmission error is also different. The following table summarizes their influence:

| Parameter | Influence on Contact Trajectory | Influence on Transmission Error |

|---|---|---|

| Vertical Wheel Position | Affects the movement of the contact trajectory in the tooth – length direction, more significant on the working surface | Affects the non – working surface more than the working surface |

| Bed Position | Causes the contact trajectory to move in the tooth – length direction, opposite to the axial wheel position | Affects the non – working surface more than the working surface |

| Axial Wheel Position | Moves the contact trajectory in the tooth – length direction, opposite to the bed position | Affects the working surface more than the non – working surface |

| Radial Cutter Position | Significantly affects the contact trajectory in the tooth – length direction, and may cause edge contact | Has a relatively large impact on the transmission error, affecting the non – working surface more than the working surface |

In general, the influence degree of displacement – type machine tool adjustment parameters on the contact trajectory is: radial cutter position > vertical wheel position > bed position > axial wheel position. The influence degree on the transmission error value is: radial cutter position > bed position > axial wheel position > vertical wheel position.

4.3 Analysis of Angle – Type Machine Tool Adjustment Parameter Errors

Angle – type machine tool adjustment parameters include tooth profile angle, cutter inclination angle, cutter rotation angle, angular cutter position, and wheel blank installation angle. The influence of these parameters on the tooth surface contact area is as follows:

- Angular Cutter Position: Changes in the angular cutter position have almost no effect on the tooth surface contact trajectory and the transmission error value at the meshing turning point.

- Tooth Profile Angle: Changes in the tooth profile angle mainly affect the tooth – height direction of the contact area. A positive change in the tooth profile angle of the working surface causes the contact trajectory to move towards the small end and the tooth tip, and a negative change causes it to move towards the large end and the tooth root. Excessive tooth profile angle error may cause edge contact at the tooth tip and tooth root. The change trend of the non – working surface is opposite to that of the working surface.

- Cutter Inclination Angle: Changes in the cutter inclination angle mainly affect the tooth – length direction of the contact area. A positive change causes the contact trajectories of the two tooth surfaces of the large gear to move towards the large end, and a negative change causes them to move towards the small end.

- Cutter Rotation Angle: Changes in the cutter rotation angle mainly affect the tooth – length direction of the contact area. A positive change in the cutter rotation angle of the working surface causes the contact trajectory to move towards the small end, and a negative change causes it to move towards the large end. On the non – working surface, both positive and negative changes cause the contact trajectory to move along the small end.

- Wheel Blank Installation Angle: Changes in the wheel blank installation angle of the working surface mainly affect the tooth – height direction of the contact area, while changes in the non – working surface mainly affect the tooth – height and tooth – length directions. A positive change causes the contact trajectories of the two tooth surfaces of the large gear to move towards the large end and the tooth root, and a negative change causes them to move towards the small end and the tooth tip. Excessive installation angle error may cause edge contact at the tooth tip and tooth root.

The influence of angle – type machine tool adjustment parameters on the contact trajectory and transmission error is also different. The following table summarizes their influence:

| Parameter | Influence on Contact Trajectory | Influence on Transmission Error |

|---|---|---|

| Angular Cutter Position | Almost no influence | Almost no influence |

| Tooth Profile Angle | Affects the tooth – height direction of the contact area, more significant on the working surface | Affects the non – working surface more than the working surface |

| Cutter Inclination Angle | Affects the tooth – length direction of the contact area, more significant on the working surface | Affects the non – working surface more than the working surface |

| Cutter Rotation Angle | Affects the tooth – length direction of the contact area, more significant on the non – working surface | Affects the working surface more than the non – working surface |

| Wheel Blank Installation Angle | Affects the tooth – height and tooth – length directions of the contact area, more significant on the non – working surface | Affects the non – working surface more than the working surface |

5. Influence of Machine Tool Adjustment Parameters on Tooth Profile

5.1 Construction of Tooth Mismatch Diagram

To study the impact of machine tool adjustment parameters on the tooth profile, a tooth mismatch diagram is proposed. According to relevant literature, the position vectors r and unit normal vectors n of the grid points on the reference tooth surface and the analyzed tooth surface are calculated. The mid – points of the grids of the reference tooth surface and the analyzed tooth surface are overlapped, and the projection of the vector of the analyzed surface on the reference tooth surface is calculated. The projection distance corresponding to each grid point on the tooth surface is defined as the mismatch amount of the tooth surface, that is: \(m_{ij}^{k}=(r_{ij}^{k} – r_{ij}^{1})\cdot n_{ij}^{1}\) where \(r_{ij}^{1}\) and \(n_{ij}^{1}\) are the position vector and unit normal vector of each grid point on the reference tooth surface respectively, \(r_{ij}^{k}\) is the position vector of each grid on the analyzed surface, and \(m^{k}\) is the mismatch amount between grid points of different tooth surfaces. The grid division point serial numbers range from 1 to 45.

5.2 Analysis of the Influence on Tooth Profile

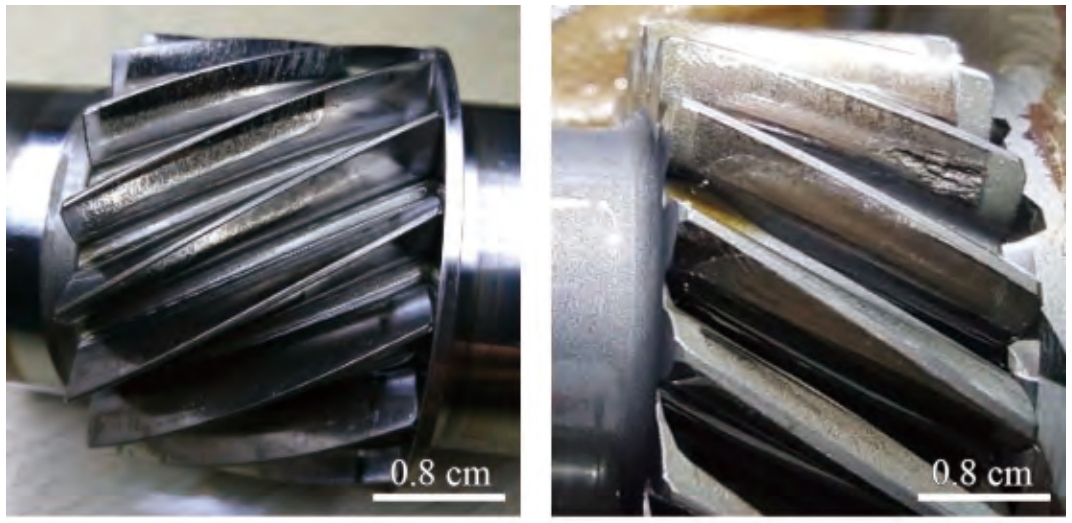

Three machine tool adjustment parameters, namely the tooth profile angle, radial cutter position, and installation angle, are selected to establish the tooth mismatch diagram, as shown in Figure 3.

[Insert Figure 3: Influence of different machine tool adjustment parameters on the small – wheel tooth profile and mismatch amount]

Through the analysis of Figure 3, the following conclusions can be drawn:

- Tooth Profile Angle: For the working surface, the change of the tooth profile angle mainly affects the pressure angle, thereby influencing the position of the contact area in the tooth – height direction. For the non – working surface, it also affects the pressure angle, as well as the helix angle and the position of the contact area in the tooth – length direction.

- Radial Cutter Position: For the working surface, the change of the radial cutter position mainly affects the helix angle, thus influencing the position of the contact area in the tooth – length direction. For the non – working surface, it affects the helix angle, pressure angle, and the position of the contact area in the tooth – height direction.

- Installation Angle: For the working surface, the change of the installation angle mainly affects the pressure angle, which in turn affects the position of the contact area in the tooth – height direction. For the non – working surface, it affects both the helix angle and the pressure angle, influencing the position of the contact area in both the tooth – length and tooth – height directions. The influence on the non – working surface is greater than that on the working surface.

- Mismatch Amount Distribution: The mismatch amount at the large end of the tooth surface is larger than that at the small end. The influence of the radial cutter position on the tooth profile is much greater than that of the tooth profile angle and the installation angle. The positive and negative changes of the tooth profile angle, radial cutter position, and installation angle have a symmetric impact on the tooth profile.

- Consistency with Contact Trajectory: The influence of the tooth profile angle, radial cutter position, and installation angle on the tooth profile is consistent with their influence on the change of the contact trajectory.

6. Conclusions

In this paper, a mathematical machining model of hypoid gears and a tooth contact analysis mathematical model for large and small wheels are established. The impacts of 9 machine tool adjustment parameters on the contact trajectory and transmission error curve of hypoid gears are analyzed. By constructing the tooth mismatch diagram, the influence of machine tool adjustment parameters on the tooth profile is elaborated. The research results provide a theoretical basis for adjusting the processing parameters of hypoid gears and optimizing the tooth surface contact area.

However, this study does not consider factors such as material properties and heat treatment processes. In future research, it is necessary to further explore the impacts of these factors on the meshing performance of hypoid gears to more comprehensively understand and improve the performance of hypoid gears in practical applications. The following table summarizes the main contributions and limitations of this study:

| Aspect | Description |

|---|---|

| Contributions | Established mathematical models; Analyzed the influence of machine tool adjustment parameters on contact trajectory, transmission error, and tooth profile |

| Limitations | Did not consider material properties and heat treatment processes |

In the future, with the continuous development of manufacturing technology and the increasing demand for high – performance mechanical products, in – depth research on hypoid gears will still be an important topic. For example, more accurate measurement methods for machine tool adjustment parameters and tooth surface quality need to be developed. In addition, the combination of multi – physical – field analysis, such as considering the influence of thermal – mechanical coupling on the meshing performance of hypoid gears, will also be a potential research direction. This can help to further improve the design and manufacturing level of hypoid gears and promote the development of related industries.