To comprehensively investigate the impact of non-metallic inclusions (hereinafter referred to as “inclusions”) in gear materials on contact damage in wind turbine gears, this paper introduces the configurational force theory, which can describe the system’s energy changes, to characterize the evolution of gear contact damage. The effects of inclusion depth, size, and arrangement on the critical contact load-bearing areas of gears are explored. Inclusions alter the stress distribution and damage patterns of gear contact damage, leading to the formation of different areas of material spalling and failure regions. The damage model based on the configurational force theory can accurately describe the contact damage problem of wind turbine gears containing inclusions.

1. Introduction

The performance of wind turbine gears directly affects the operational efficiency and reliability of wind turbine systems. Although gear materials have high fatigue resistance after heat treatment, some inevitable non-metallic inclusions still exist in these materials, disrupting their uniformity and integrity. Gear failure can lead to gearbox malfunctions or even shutdowns of the entire wind turbine, causing significant economic losses and safety hazards to the wind power industry. Therefore, in-depth research on the influence mechanism of inclusions in gear materials on gear contact damage behavior is crucial for improving the lifespan and performance of wind turbines.

2. Literature Review

In recent years, the failure behavior of gear contact damage has gradually garnered attention from scholars. Han Cuncang et al. analyzed the fatigue failure forms and transformation mechanisms beneath the gear surface and proposed a criterion based on the local yield strength value method to predict fatigue failure forms and fatigue crack sources. Material factors affecting gear contact fatigue performance also include material crystallographic characteristics and inclusions. Jallahamadi et al. analyzed the impact of inclusion hardness, size, depth, and number on contact fatigue damage and derived a life equation considering inclusion distribution that can predict the influence of inclusions on material fatigue life. Gupta et al. proposed a new method based on micro-macro modeling to quantify the influence of inclusions on the macro and micro properties of steel plates, considering the effect of stress distribution on the material properties of the inclusion matrix. Feng Lei et al. used the finite element method to study the local mechanical behavior around inclusions and analyzed the influence of inclusion properties, locations, multiple inclusions, and cyclic plasticity on local stress concentration. Moghaddam et al. proposed a model describing the formation of butterfly-wing shapes around non-metallic inclusions and established two-dimensional and three-dimensional finite element models to study the stress distribution in Hertzian loaded areas containing non-metallic inclusions.

To reveal the contact fatigue failure mechanism of large, heavy-duty wind turbine gears, a research team established a multi-factor coupling gear contact fatigue failure analysis model incorporating macro and micro material characteristics such as material crystallography, phase composition, inclusions, and hardness gradients, studying the damage evolution process of gears from the microscale . Based on the mechanical properties and microstructure gradients of gears from the exterior to the core, Wang et al. proposed a numerical model integrating both, detailing the study of crystallographic anisotropy in microstructures. Wei et al. established a microstructural finite element model, estimated fatigue failure probabilities using a modified Dang Van criterion, and studied the influence of microstructure, inclusions, and surface roughness on gear contact fatigue, providing theoretical support for revealing the failure mechanism of gear contact fatigue at the microscale.

Based on the Brown-Miller multiaxial fatigue criterion, the contact fatigue life of gears with inclusions was predicted, revealing the influence mechanism and laws of subsurface inclusions on contact fatigue performance . Zhang et al. focused on wind turbine gears, established a tooth surface simulation model for infinite plate problems at the mesoscopic scale, and introduced “surface moving loads” to simulate the rolling contact effect during actual wind turbine gear operation, studying the gear damage evolution process.

3. Complexity and Specificity of Contact Conditions in Wind Turbine Gearboxes

The complexity and specificity of contact conditions in wind turbine gearboxes are mainly reflected in material, structure, and operating conditions.

Firstly, under ultra-high cycle contact loads, the internal microstructure of gear materials (including complex factors such as crystals and inclusions) significantly affects the mechanical properties and damage behavior of gears in contact, leading to local deformation and phase transformation, and generating microscopic damage. Secondly, the complex structural shape of gears results in uneven contact stress distribution along the tooth width, making it prone to stress concentration areas. Thirdly, the complexity and specificity of operating conditions mean that gears are prone to severe failure phenomena such as pitting, spalling, and tooth breaking under low-speed, heavy-load, and ultra-high cycle contact conditions. Additionally, contact loads have coupling effects (such as radial and tangential loads), which exacerbate local stress concentration and accelerate gear failure.

4. Configurational Force Theory and Gear Contact Damage Modeling

Changes in material defect configurations (such as position and size) have a significant impact on the total potential energy of the material. When the configuration changes, a configurational force is generated that drives the change in material defects, leading to discontinuities in the internal structure and changes in system energy. Therefore, to more comprehensively explore the influence of inclusions on wind turbine gear contact damage, this paper introduces the configurational force theory to describe the evolution of gear contact damage.

This paper selects the contact load-bearing area of gears for gear contact simulation analysis, analyzing the influence of inclusion location, size, and the arrangement of two inclusions on the evolution of gear contact damage under contact loads.

4.1 Characteristics of the Load-Bearing Area of Gear Contact Surfaces

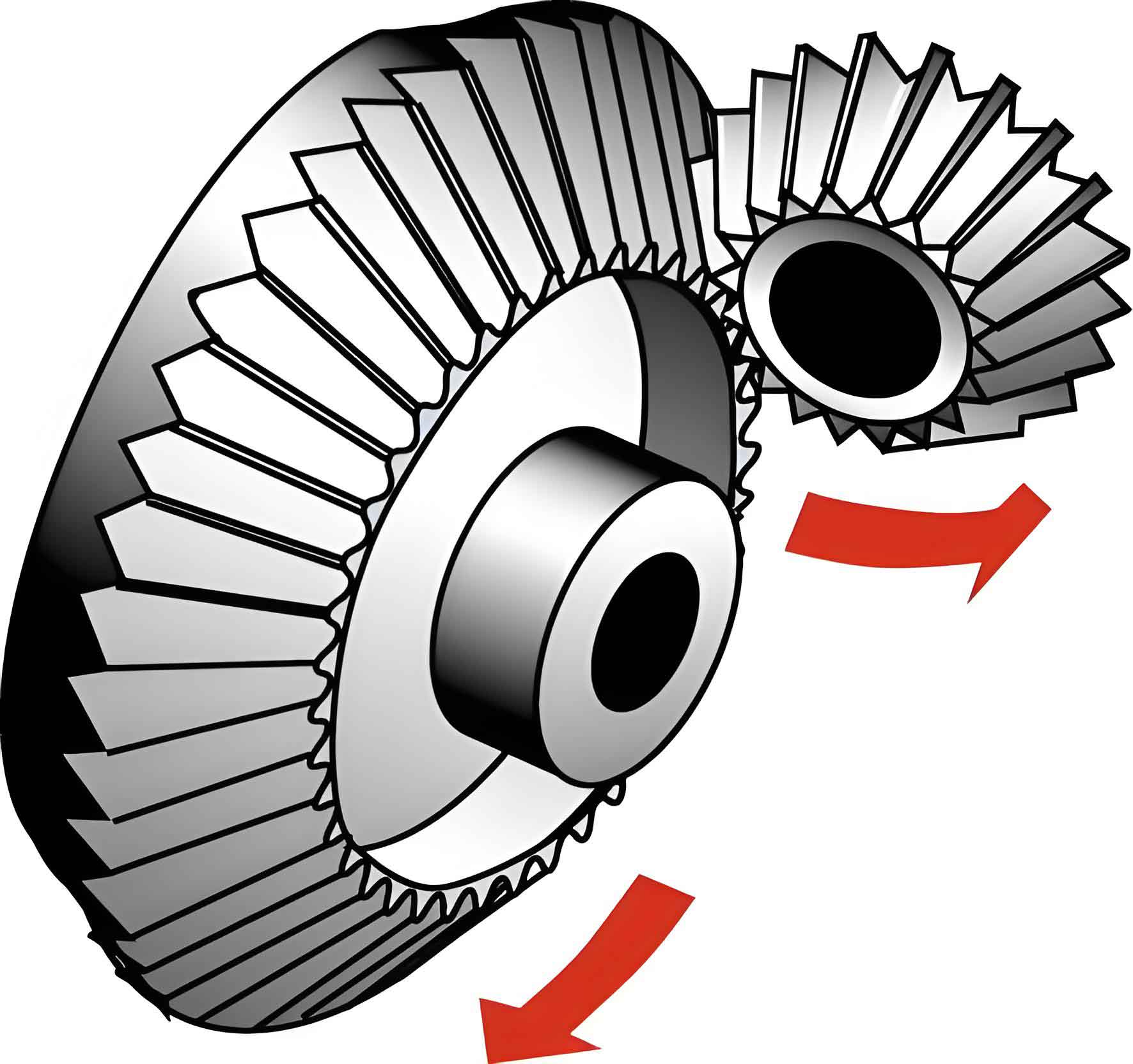

This paper adopts a 4.55 MW gearbox with a composite planetary gear train. To meet the actual operating conditions of wind turbines, wind turbine gearboxes are typically composed of gear pairs with high transmission ratios. The gearbox transmission system is shown in Figure 1, where the intermediate stage consists of an intermediate gear and an intermediate gear shaft. During operation, the intermediate gear shaft is most susceptible to failure, with tooth surfaces often experiencing pitting, spalling, and tooth breaking, as shown in Figure 2. The primary source of gear contact fatigue damage is non-metallic inclusion alumina (Al2O3). Therefore, Al2O3 inclusions are selected as the research object in this paper. Aluminum is commonly used as a deoxidizer, and steel often contains deoxidation products such as Al2O3. Al2O3 inclusions typically exhibit smooth spherical (or circular) shapes.

Table 1: Gear Parameters

| Parameter | Value |

|---|---|

| Number of teeth | 30 |

| Normal module (mm) | 12.2 |

| Pressure angle (°) | 25 |

| Helix angle (°) | 11.35 |

| Center distance (mm) | 685 |

| Tooth width (mm) | 203 |

| Elastic modulus (GPa) | 2.07 |

| Poisson’s ratio | 0.3 |

| Density (kg/m³) | 7800 |

The structures of gear shafts and intermediate gears are complex. This study focuses on the contact damage of gears in the load-bearing area during meshing and reduces the computational scale by simplifying the gear’s geometric structure and meshing process. Based on Hertz contact theory, the contact between gears during meshing is simplified into contact between two cylinders, as shown in Figure 3.

When analyzing the contact state of gearboxes using dynamic analysis methods and mechanical theories, rated operating conditions, actual operating conditions, and extreme operating conditions are primarily considered. In this study, special attention is given to the extreme conditions that wind turbine gearboxes may encounter during actual operation. Therefore, this paper selects representative extreme conditions that clearly reflect the gear contact damage state with inclusions during meshing. These conditions represent the operating state of the gearbox at maximum power output, aiming to simulate the mechanical properties and damage state of wind turbine gears with inclusions under high loads to assess the influence of inclusions on gear contact damage. When the gear is under extreme operating conditions in actual operation, the normal load is 1790 N/mm. When the gears mesh at the pitch point, the Hertz contact pressure at the contact center is p = 1059.49 MPa, and the contact half-width is a = 1.077 mm.

4.2 Finite Element Model of Gear Contact

This paper focuses on the contact damage of the load-bearing area of gears during meshing. The selected meshing state of a gear pair is shown in Figure 4, and a finite element model simulating gear work damage is established based on the semi-infinite plate problem, simulating the rolling effect of the entire process of gear engagement and disengagement, as shown in Figure 5. The model has a length of 20 mm in the width direction (X-direction) and 10 mm in the depth direction (Y-direction). The red area in Figure 5 represents the inclusion area, with an inclusion radius r = 0.05 mm as an example.

The driving force Jk integral describing material damage evolution is derived from the perspective of energy gradients, with a detailed derivation process provided in reference . To describe the damage in the gear material, Jk is utilized. When gears mesh, surface stresses are generated in the contact area of the tooth surfaces.