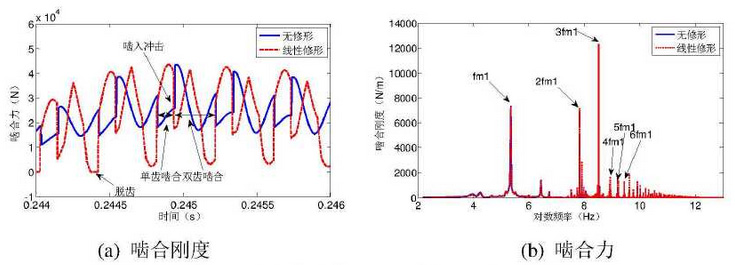

Analyze the time-domain curve of meshing stiffness and meshing force of the gear under the optimal modification amount, and compare it with the gear without modification, as shown in the figure. It can be seen from the figure that the tooth profile modification effectively alleviates the sharp change of meshing stiffness when single and double teeth are alternately meshed, and the maximum value of dynamic meshing force of gear is significantly reduced. Locally enlarge the time-domain curve of meshing force without modification and linear modification, as shown in Figure a. It can be seen from the figure that the modification makes the meshing impact load produced by the alternation of single and double teeth significantly reduced, but the meshing force in the single tooth meshing area increased. The spectrum of meshing force without modification and linear modification is shown in Figure B. in order to analyze the frequency characteristics in a wide frequency band, the frequency of abscissa is logarithmic. It can be seen that the tooth profile modification has little effect on the amplitude corresponding to the first-order meshing frequency, and increases the amplitude corresponding to the second-order and fourth-order meshing frequency, while the amplitude corresponding to the other higher-order meshing frequency decreases to some extent.

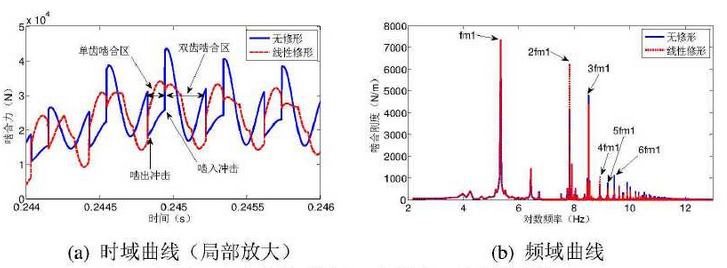

Further analyze the time domain curve of the meshing stiffness and meshing force of the gear under the critical shape modification amount, and make a comparative analysis with the gear without shape modification, as shown in the figure. It can be seen from the figure that under the critical modification amount, the tooth profile modification does not effectively alleviate the sharp change of meshing stiffness, at the same time, the coincidence degree of the gear is reduced, and the maximum value of the dynamic meshing force of the gear is not significantly lower than the maximum value of the meshing force of the gear without modification, and there is the phenomenon of tooth shedding. Further enlarge the time-domain curve of meshing force without modification and linear modification, as shown in Figure a. It can be seen from the figure that although the modification makes the meshing impact load of single and double teeth significantly reduced when the meshing angle alternates, the meshing force in the single tooth meshing area significantly increases, which is also the main reason that the maximum meshing force does not significantly reduce after the modification. According to the spectrum diagram B, the amplitude of the second and third order meshing frequency increases obviously under the critical modification compared with the gear without modification.

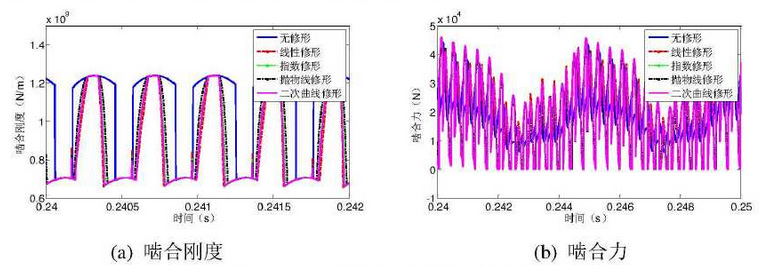

Generally speaking, for the heavy-duty vehicle gear transmission system studied in this paper, under different modification types, there is an optimal modification amount to minimize the dynamic load of the gear, and the optimal modification amount is less than the deformation amount of the highest point of single tooth meshing under the action of the average torque of the engine; when the modification amount exceeds a certain critical value, the dynamic load of the modified gear exceeds the dynamic load of the unmodified gear; with other modifications Compared with the shape type, the dynamic load reduction of the linear modification is the largest, but the critical modification is the smallest; under the optimal modification, the meshing force of the modified gear is significantly reduced on the amplitude corresponding to the higher-order meshing frequency, while the meshing impact load produced by the alternation of single and double teeth is significantly reduced, but the meshing force in the single tooth meshing area is increased; under the critical modification, the meshing force of the modified gear is significantly reduced The magnitude of the second-order and the third-order meshing frequency increases obviously. Although the meshing impact load produced by the alternation of single and double teeth decreases obviously, the meshing force in the single tooth meshing area increases obviously, and there is the phenomenon of tooth detaching at the same time. Under the optimal modification, the coincidence degree of gears is basically unchanged, while under the critical modification, when the meshing force is small, the coincidence degree of gears is reduced.