This article delves deep into the innovative realm of the new type of plane helical cylindrical gear. By presenting its novel machining method, comprehensive geometric characteristics, and superior meshing performance, it showcases how this gear is set to revolutionize the field of mechanical transmission. Through in – depth research and analysis, we aim to provide a thorough understanding of this gear’s potential applications and future development directions, highlighting its significance in enhancing the efficiency and reliability of mechanical systems.

1. Introduction

1.1 Background of Gear Technology

Gears are the heart of countless mechanical systems, facilitating the smooth transfer of power and motion. Among them, cylindrical gears are widely used in various industries, such as automotive, aerospace, and industrial machinery. Traditional cylindrical gears, including spur gears, helical gears, herringbone gears, and circular – arc – tooth – trace cylindrical gears, have their own characteristics and limitations. For example, the machining efficiency of spur gears is relatively low, and helical gears may suffer from axial forces.

1.2 Limitations of Conventional Cylindrical Gear Machining Methods

The existing machining methods for cylindrical gears, like hobbing and shaping, have been continuously improved over the years. However, they still cannot achieve continuous machining across the entire tooth width, which restricts the machining efficiency. High – speed dry hobbing has improved production efficiency and tooth surface integrity to some extent, but it requires further optimization of process parameters and the tool is prone to wear. Additionally, due to machining and installation errors, as well as elastic deformation, gear pairs are likely to experience uneven loading during meshing, reducing the service life of the gears.

1.3 Significance of the New Type of Plane Helical Cylindrical Gear

The new type of plane helical cylindrical gear and its machining method offer a promising solution to the above – mentioned problems. This gear can not only improve the machining efficiency but also enhance the bearing capacity of gear pairs, making it a significant advancement in gear technology.

2. Machining Principle of the Plane Helical Cylindrical Gear

2.1 Plane Helical Tooth Line Formation Principle

2.1.1 Comparison with Traditional Machining Methods

Traditional gear – machining methods like hobbing and shaping have limitations in achieving continuous machining across the entire tooth width. In contrast, the new method aims to revolutionize this by using a rotating large cutter head. As shown in Table 1, we can clearly see the differences between the traditional and the new machining methods.

| Machining Method | Machining Efficiency | Tooth – width Machining Continuity | Tool Wear |

|---|---|---|---|

| Hobbing | Limited by non – continuous tooth – width machining | Discontinuous | Relatively high in high – speed dry hobbing |

| Shaping | Low machining efficiency | Discontinuous | Varies depending on the material and process |

| New method (rotating large cutter head) | High, enables continuous machining | Continuous | Reduced due to multiple – tool cooperation |

2.1.2 The Formation Process

The plane helical tooth line is formed through a unique motion combination. When machining a rack, if the cutter head rotates at a speed of \(\omega_{D}\) and the rack is stationary in the radial direction of the cutter head, the machined tooth groove is arc – shaped. However, to form a plane helical tooth line, the rack moves linearly along the radial direction of the cutter head at a certain speed v while the cutter head rotates. As the cutter head rotates one circle, the rack moves a tooth pitch. The speed relationship is expressed as \(\frac{2 \pi}{\omega_{D}}=\frac{\pi m}{v}\), where m is the module. This ensures that the cutter can continuously machine different tooth grooves, forming a plane helical tooth line. Figure 1 shows the formation principle of the spiral tooth line.

When machining a cylindrical gear, the process is more complex. It includes depth – cutting and generating machining. During depth – cutting, the speed v of the rack movement is converted into the angular velocity \(\omega_{c}\) of the cylindrical workpiece. The tooth blank needs to rotate and move axially along the cutter head to complete the depth – cutting of the tooth groove. During generating machining, additional rotational speed and radial linear movement are added to the tooth blank to form the involute tooth profile.

2.2 Gear Machining Cutter Head

2.2.1 Multi – Tool Arrangement

To improve machining efficiency and accuracy, multiple tools are evenly arranged on the large cutter head according to the plane helical line. The pitch of the helical line is the same as the gear tooth pitch. Figure 2 shows the installation principle of the tool spiral line.

2.2.2 Tool Classification and Characteristics

Among these tools, the tool with the smallest or largest installation radius (installation radius is \(R_{I}\)) is the main cutting tool, and the rest are auxiliary cutting tools. The auxiliary cutting tools are installed at a lower height than the main cutting tool and are used for pre – cutting the workpiece tooth groove, reducing the cutting amount and cutting force of the main cutting tool. The main and auxiliary cutting tools have the same shape. The main cutting tool is composed of an outer cutting edge and an inner cutting edge. The outer cutting edge generates the concave surface of the gear tooth, and the inner cutting edge generates the convex surface of the gear tooth. The curvature radius of the inner cutting edge is smaller than that of the outer cutting edge. The pitch curvature radii \(R_{a b}\) and \(R_{i b}\) of the outer and inner cutting edges are \(R_{o b}=R_{T}+\frac{\pi m}{4}\) and \(R_{i b}=R_{T}-\frac{\pi m}{4}\) respectively, where \(R_{T}\) is the installation radius of the main cutting tool. Table 2 summarizes the characteristics of different tools.

| Tool Type | Installation Height | Function | Cutting Edge Characteristics |

|---|---|---|---|

| Main cutting tool | Highest among tools | Final shaping of the tooth surface | Outer edge for concave tooth surface, inner edge for convex tooth surface, different curvature radii |

| Auxiliary cutting tool | Lower than main cutting tool | Pre – cutting the tooth groove | Similar to main cutting tool in shape |

2.3 Generating Motion Principle

2.3.1 Movement of Machining Components

During the machining process, the cutter head rotates at an angular velocity \(\omega_{D}\) around the \(Y_{D}\) axis as the main motion, and the gear blank rotates at an angular velocity \(\omega_{C}\) around the \(z_{c}\) axis. To ensure accurate machining of the tooth groove, the angular velocity \(\omega_{C}\) of the gear blank and the angular velocity \(\omega_{D}\) of the cutter head should satisfy \(\frac{\omega_{C}}{\omega_{D}}=\frac{1}{Z}\), where Z is the number of gear teeth. Figure 3 shows the movement diagram of the machining components.

2.3.2 Formation of Involute Tooth Profile

To machine the involute tooth profile, the gear blank undergoes a generating motion relative to the machining tool. When machining the right – hand tooth surface, the cutter head rotates clockwise around the \(Y_{D}\) axis at an angular velocity \(\omega_{D}\), and the gear blank rotates clockwise around the \(z_{c}\) axis at an angular velocity \((\omega_{c}-\omega_{s})\) and moves linearly along the positive \(x_{c}\) direction at a speed \(v_{s c}\), satisfying \(v_{x c}=r \omega_{s}\), where \(\omega_{s}\) is the additional rotational speed of the tooth blank and r is the pitch circle radius of the gear. The left – hand tooth surface is machined in a similar way, with the gear blank rotating at an angular velocity \((\omega_{C}+\omega_{s})\) and moving along the negative \(x_{c}\) direction.

3. Machining and Simulation of the Plane Helical Cylindrical Gear

3.1 Machining Cutter Head Model

3.1.1 Parameter Selection

The parameters of the gear and machining tool are crucial for the machining process. As shown in Table 3, for a specific plane helical cylindrical gear, we select parameters such as the number of teeth, module, pressure angle, etc.

| Parameter | Value |

|---|---|

| Number of teeth | 30 |

| Module /mm | 5 |

| Pressure angle \(\alpha\) / (°) | 20 |

| Tooth width B /mm | 40 |

| Addendum coefficient \(h^{*}_{a}\) | 1 |

| Bore diameter d /mm | 40 |

| Cutter head radius \(R_{0}\) /mm | 200 |

| Number of inserts | 4 |

3.1.2 Model Building

Using SOLIDWORKS software, we can build the models of the tooth blank and machining cutter head based on the selected parameters. The cutter head and tools are then imported into the VERICUT tool management library. The gear machining tool forms a 90 – degree angle with the cutter head plane, and the cutting edge rotates to form a cutting – edge cylindrical surface in principle.

3.2 Machining Simulation

3.2.1 Simulation Setup

After building the models, we need to set reasonable milling parameters and import the NC program for gear simulation machining. Figure 4 shows the simulation machining of the gear.

3.2.2 Simulation Results

The simulation process shows no interference or collision. The cutter head can continuously machine the plane helical cylindrical gear, achieving continuous cutting across the entire tooth width. The machined gear tooth surface has concave and convex tooth surfaces, and the radius of the tooth line of the concave tooth surface is slightly larger than that of the convex tooth surface, forming a slightly drum – shaped tooth. Table 4 summarizes the simulation results.

| Simulation Aspect | Result |

|---|---|

| Machining Process | Continuous cutting across the entire tooth width, no interference |

| Tooth Surface Characteristics | Concave and convex tooth surfaces, concave tooth – line radius > convex tooth – line radius, slightly drum – shaped tooth |

3.3 Actual Machining

3.3.1 Machining Machine Tool Development

Based on the machining method and simulation results, a special machining machine tool for plane helical cylindrical gears has been developed. The machining cutter head of the machine tool has 6 through – type tool slots for installing tools. The cutter head is fixed on the machine tool by bolts, and the tools in the through – type tool slots are positioned by threaded bolts in the radial direction to ensure stability during high – speed rotation. Figure 5 shows the plane helical cylindrical gear machining machine tool.

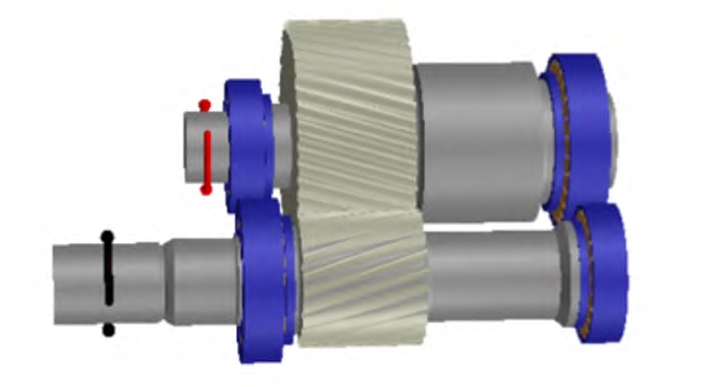

3.3.2 Machining Results

The actual machining results show that the machine tool can achieve continuous cutting across the entire tooth width of the gear using hard – alloy customized special tools. The machining efficiency is significantly higher than that of traditional hobbing for cylindrical gears. The plane helical cylindrical gear obtained from actual machining is shown in Figure 6.

4. Main Geometric Parameters and Meshing Analysis of the Plane Helical Cylindrical Gear

4.1 Main Geometric Parameters and Characteristics of the Plane Helical Cylindrical Gear

4.1.1 Parameter Definition

The plane helical cylindrical gear has five main parameters: module m, number of teeth Z, pressure angle \(\alpha\), tooth width B, and the curvature radius \(R_{T}\) of the spiral line at the tooth width mid – line (the installation radius of the main cutting tool).

4.1.2 Tooth Surface Characteristics

The tooth surface of the plane helical cylindrical gear is divided into concave and convex tooth surfaces. The curvature radius of the tooth line of the concave tooth surface is slightly larger than that of the convex tooth surface. At the same spiral line expansion angle, the difference between the tooth – line radius of the concave tooth surface \(R_{N}\) and that of the convex tooth surface \(R_{W}\) is \(R_{N}-R_{W}=\frac{\pi m}{2}\). The middle – section tooth profile of the gear is an involute tooth profile, and the tooth profiles of other sections are approximately involute, with a slight twist and offset compared to the middle – section. Table 5 summarizes the geometric characteristics of the tooth surface.

| Tooth Surface | Tooth – line Radius Relationship | Tooth Profile Characteristics |

|---|---|---|

| Concave tooth surface | \(R_{N}=R_{W}+\frac{\pi m}{2}\) | Generated by the outer cutting edge of the tool |

| Convex tooth surface | \(R_{W}=R_{N}-\frac{\pi m}{2}\) | Generated by the inner cutting edge of the tool |

| Overall | Middle – section is involute, other sections are approximately involute with twist and offset |

4.1.3 Tooth – width and Tooth – thickness Characteristics

The pitch of the spiral tooth line is equal to the gear tooth pitch. At the tooth width mid – line, the circumferential tooth thickness \(S_{C}\) and the circumferential tooth space width \(P_{C}\) are equal, both being half of the circumferential tooth pitch P, i.e., \(S_{C}=P_{C}=\frac{P}{2}\). In other sections, the circumferential tooth space width is greater than the circumferential tooth thickness. This characteristic can ensure that the tooth – surface contact force of the gear pair is mainly distributed in the middle of the tooth surface, reducing stress concentration at the tooth roots at both ends of the gear teeth and effectively reducing the meshing uneven loading caused by machining and installation errors.

4.2 Meshing Characteristics Analysis of the Plane Helical Cylindrical Gear

4.2.1 Meshing Model Setup

To verify the gear – transmission contact line, two plane helical cylindrical gear models with the same parameters and opposite helical directions are used for meshing characteristic analysis. The gear pair is accurately assembled in SOLIDWORKS software according to the meshing conditions, and the interference – checking tool is used to analyze the tooth – surface interference of the gear pair.

4.2.2 Meshing Results

The analysis results show that the theoretical contact interval is mainly distributed in the middle 80% – 90% area of the contact tooth surfaces of the pair of gears, and the forces at both ends of the gear teeth are small. This can effectively reduce the bending stress at the tooth roots at both ends of the gear teeth and improve the bearing capacity of the gear pair. Figure 7 shows the verification of the tooth – contact line.

5. Conclusion and Future Outlook

5.1 Research Summary

In this article, a new machining method for cylindrical gears using a large cutter head for continuous cutting across the entire tooth width has been proposed. Through VERICUT software simulation, the feasibility of this method has been verified. The geometric characteristics of the plane helical cylindrical gear have been analyzed, and its excellent meshing performance has been demonstrated. The new machining method can improve machining efficiency, and the plane helical cylindrical gear has unique geometric features that can enhance the bearing capacity of gear pairs.

5.2 Future Research Directions

Although significant progress has been made in the research of plane helical cylindrical gears, there is still much room for further exploration. In the future, it is necessary to calculate the tooth – surface equation of this gear to gain a more in – depth understanding of its geometric shape. Analyzing the distribution of tooth – surface contact stress and tooth – root bending stress will help optimize the gear design. Additionally, building a gear – transmission experimental device to study the transmission characteristics of plane helical cylindrical gears will further promote the practical application of this new – type gear.

5.3 Potential Applications

The plane helical cylindrical gear has great potential in various fields. In the automotive industry, it can be used in transmissions to improve power – transmission efficiency and reduce noise. In the aerospace field, its high – strength and high – efficiency characteristics can meet the requirements of lightweight and high – performance mechanical systems. In industrial machinery, it can enhance the reliability and durability of equipment, reducing maintenance costs.

In conclusion, the new type of plane helical cylindrical gear represents a significant advancement in gear technology. With further research and development, it is expected to bring about more innovation and development in the field of mechanical transmission.