1. Test to limit the effect of steel hardenability on distortion

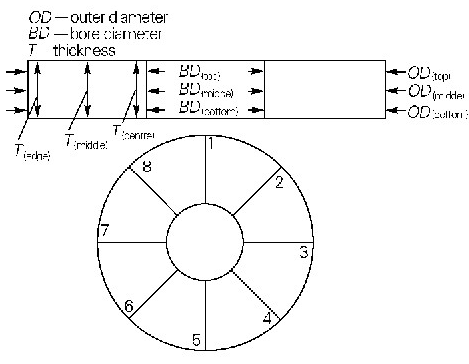

1) Sample

The test adopts two sizes of disk-shaped specimen with inner hole:

2) Test steel

Two different hardenability steels are selected: (1) low hardenability steel en353; (2) high hardenability steel en355. All samples are treated by the same standard carburizing process.

3) Comparison of distortion results

(1) Distortion of different hardenability of the same steel

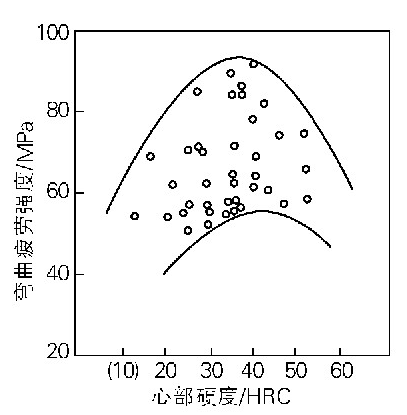

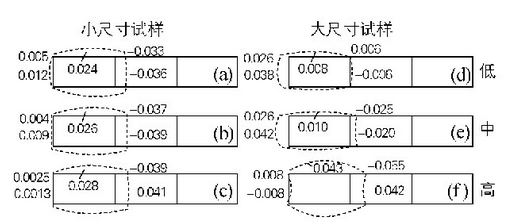

Hardness test results of low hardenability steel en353. For small size samples, the hardness and distortion of the three samples are similar due to the hardenability of the core. For large-scale samples, the distortion of the three samples is different because of the different hardness of the center. With high hardenability, the distortion is also large, as shown in Fig. 25. The test results show that the high hardness distortion of the center is large, and the similar hardness distortion of the center is also similar.

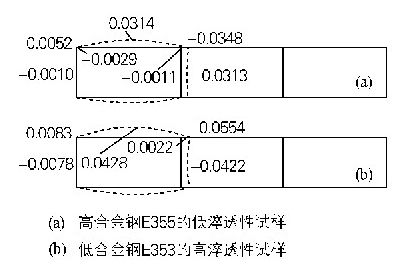

(2) Distortion of similar hardenability of different steels

For the high hardenability sample of low hardenability steel en353 and the low hardenability sample of high hardenability steel en355, because of their similar hardenability, their distortion size and characteristics are also similar.

From the above test results, it can be seen that as long as the hardenability (or core hardness) of steel is similar, its distortion is also similar, that is, the dispersion of distortion is reduced, which provides favorable conditions for controlling distortion.

2. Production and application of limiting hardenability of steel

The distortion tendency of 20crmnnimoh, a kind of gear steel with high hardenability for driving axle of engineering vehicle, is compared with that of the original 20CrMnTi common steel after carburizing and quenching. Figure 27 shows the change of the center of contact area [20]. From the comparison results of the two figures, it can be seen that although the hardenability of 20crmnnimoh steel is higher than that of 20CrMnTi steel, its size change (dispersion) is significantly smaller than that of 20CrMnTi steel due to the narrow bandwidth controlled, which is conducive to the processing size reservation in production.

It is shown from the above examples that, for the distortion of gear heat treatment, the hardenability of steel is important, but more importantly, the hardenability bandwidth of steel, that is, the fluctuation of hardenability. Because the hardenability of steel is very important to the distortion of gear heat treatment, hardenability has been brought into the steel standard in many countries. In recent years, the width of hardenability band has been further narrowed. For example, the German DIN EN 10084-1998 “technical delivery conditions of carburized and quenched steel” has newly stipulated the narrow hardenability steel (HH and HL series), and its width has been reduced from 8 HRC of ordinary hardenability steel (H Series) to 5 HRC. The new standard GB / T 5216-2004 “ensure hardenability structural steel” issued in 2004 also reduces the width of hardenability band compared with the original standard.