According to the formula, the value of each calculation coefficient and the basic parameters of spiral bevel gear, the values of tooth surface contact stress and tooth root bending stress under various working conditions are obtained. Comparison between theoretical calculated stress and finite element contact analysis results.

It can be seen from the results that there is a certain deviation between the maximum tooth surface contact stress and tooth root bending stress obtained by finite element analysis and the theoretical calculation value. This result may be due to the fact that the finite element analysis is an ideal environment and does not take into account the influence of factors such as shaft and bearing friction, deformation and tooth surface friction.

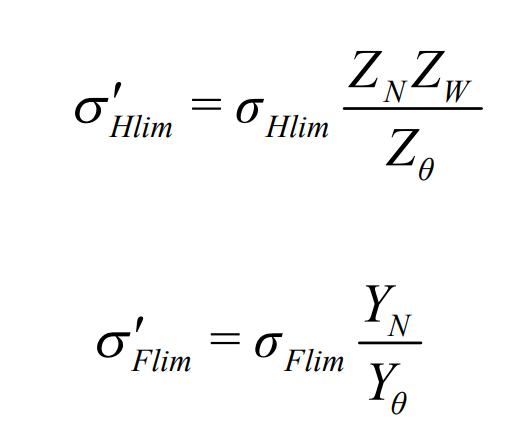

In order to obtain the bearing capacity of this pair of spiral bevel gears, the tooth surface contact strength and tooth root bending strength are checked respectively. Contact fatigue limit stress of spiral bevel gear σ‘ Hlim and root bending fatigue limit stress σ’ Flim calculations are:

Where, σ Hlim is the contact fatigue limit stress of the tested tooth surface, Zn is the life coefficient for calculating the contact stress of the tooth surface, ZW is the working hardening coefficient, Z θ Is the temperature coefficient; σ Flim is the bending fatigue limit stress of the tooth root of the test gear, yn is the life coefficient for bending calculation, y θ Is the temperature coefficient.

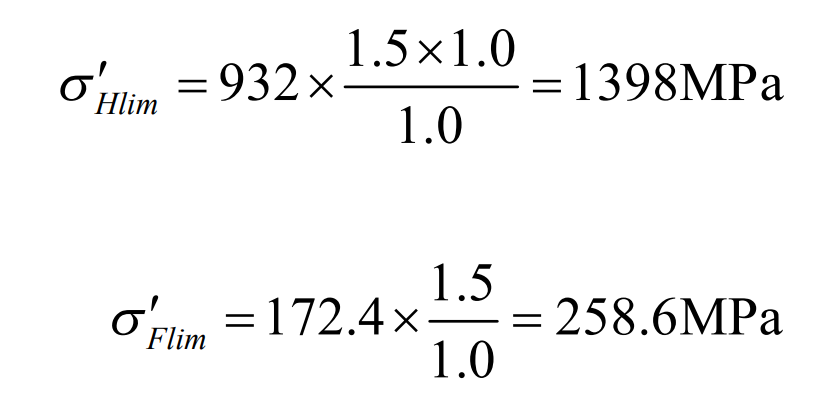

The selection of the above parameters is related to the material and working environment of the spiral bevel gear. The parameter value is selected according to the 95% reliability under the modulation steel material, general working environment and the life coefficient required by the test.

According to the formula, the tooth surface contact fatigue limit stress of spiral bevel gear can be obtained σ‘ Hlim and root bending fatigue limit stress σ‘ Flim values are:

The comparison between the stress results of finite element analysis and theoretical calculation and the fatigue limit stress in the formula shows that under the above three working conditions, the contact stress of tooth surface calculated by finite element analysis and theoretical formula is less than the contact fatigue limit stress of tooth surface; The bending stress of the tooth root obtained by finite element analysis is less than the fatigue limit stress, while the contact stress of the tooth surface calculated by the theoretical formula is slightly greater than the fatigue limit stress under the working condition of 895.000n · M. The strength check results show that the strength of this pair of spiral bevel gears under the working conditions of 447.500n · m and 223.750n · m meets the service requirements; The reliability is low under the working condition of 895.000n · M.

The theoretical stress calculation formula of spiral bevel gear is of great significance to guide the design and calculation of spiral bevel gear. However, a large number of correlation coefficients are introduced into the theoretical calculation formula, and the selection of coefficients largely depends on the designer’s experience, which brings some limitations to the stress calculation of spiral bevel gear. Moreover, the theoretical formula calculation formula can only obtain the maximum stress value of spiral bevel gear under specific working conditions, and can not accurately obtain the stress at each position on the tooth surface. However, the stress at any time and at any position can be obtained by ABAQUS analysis.