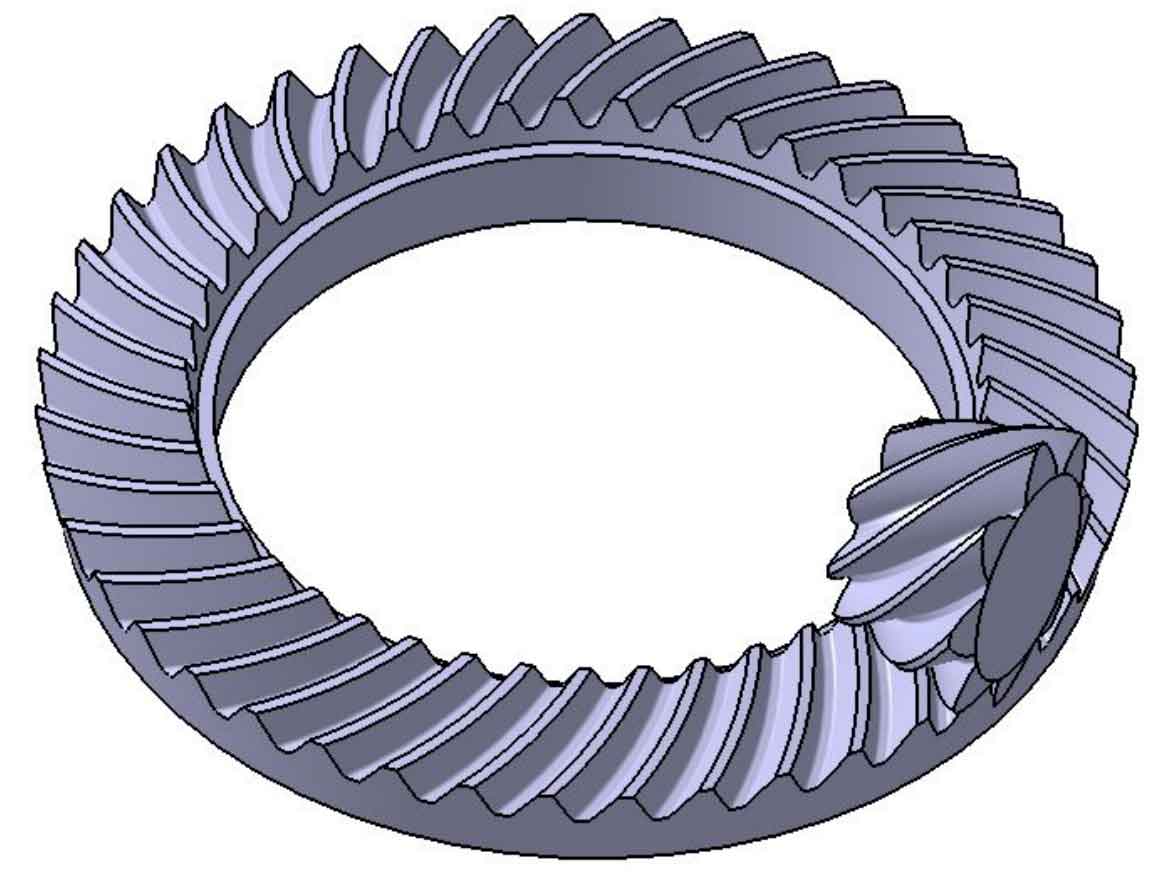

Aiming at the problem that it is difficult to obtain the tooth surface coordinates of HFT hypoid gears, this chapter proposes a mathematical modeling method of tooth surface based on MATLAB, which can automatically calculate the tooth surface coordinates. Firstly, the coordinate transformation matrix from tool to workpiece is established according to Gleason machine tool, then the tooth surface coordinate solution equation is established according to the machining parameters of hypoid gear machine tool and tooth blank parameters, and then the estimated value of gear meshing midpoint is obtained based on the machining principle of hypoid gear, which is used as the initial value to solve the coordinates of other points on the tooth surface, and finally the HFT type hypoid gear tooth surface coordinate solution program surf is established. In order to verify the proposed method, a light truck hypoid gear is taken as an example to obtain the gear tooth surface coordinates, which are imported into CATIA software to obtain the three-dimensional model of the hypoid gear set, and the established model is compared with the actual hypoid gear surface. It can be seen that the difference between the established tooth surface and the actual tooth surface is small.

A method for calculating the tooth surface coordinates of hypoid gears based on MATLAB is proposed. This method has the following advantages:

(1) A detailed actual gear processing process is established, which is related to the coordinate transformation of tooth surface points in the mathematical model of hypoid gear.

(2) A calculation method for automatically estimating the meshing midpoint of hypoid gears and quickly calculating the coordinates of tooth points is proposed. Compared with domestic methods, this calculation method can improve the calculation accuracy and speed. This modeling method can be applied to solve the coordinates of similar hypoid gears.

(3) A complete three-dimensional solid modeling method of hypoid gear is established, which provides a basis for the study of contact analysis of hypoid gear based on finite element.