Table 1 shows the basic parameters of hypoid gears, and table 2 shows the basic parameters of large and small wheel machine tools with the tool inclination half generation method. Based on NS normal datum, the solid model of hypoid gear is established by tool inclination semi generating method.

| Parameters | Offset distance E/mm | Axis intersection angle σ / (°) | Number of headers Z0 | Number of teeth Z | Initial installation angle β V/(°) | Cutting edge radius RI/mm | Tooth profile pressure angle α 0/(°) | Tool direction angle σ 0/(°) | Regrinding angle Ψ/ (°) | Rear angle of main blade γ a/(°) | Anterior horn γ s/(°) |

| Hypoid gear pinion concave | 38.1 | 90 | 17 | 11 | -21.176 | 1324.49 | 19.445 | 22.93 | 4.705 | 12.673 | 9.642 |

| Hypoid gear pinion convex | 38.1 | 90 | 17 | 11 | -10.588 | 1305.95 | 20.554 | 22.93 | 4.935 | 13.389 | 10.320 |

| Hypoid gear wheel concave | 38.1 | 90 | 17 | 47 | 10.588 | 1030.74 | 17.485 | 22.93 | 4.304 | 12.678 | 10.290 |

| Hypoid gear wheel convex | 38.1 | 90 | 17 | 47 | 21.176 | 1276.45 | 22.515 | 22.93 | 5.319 | 13.382 | 9.601 |

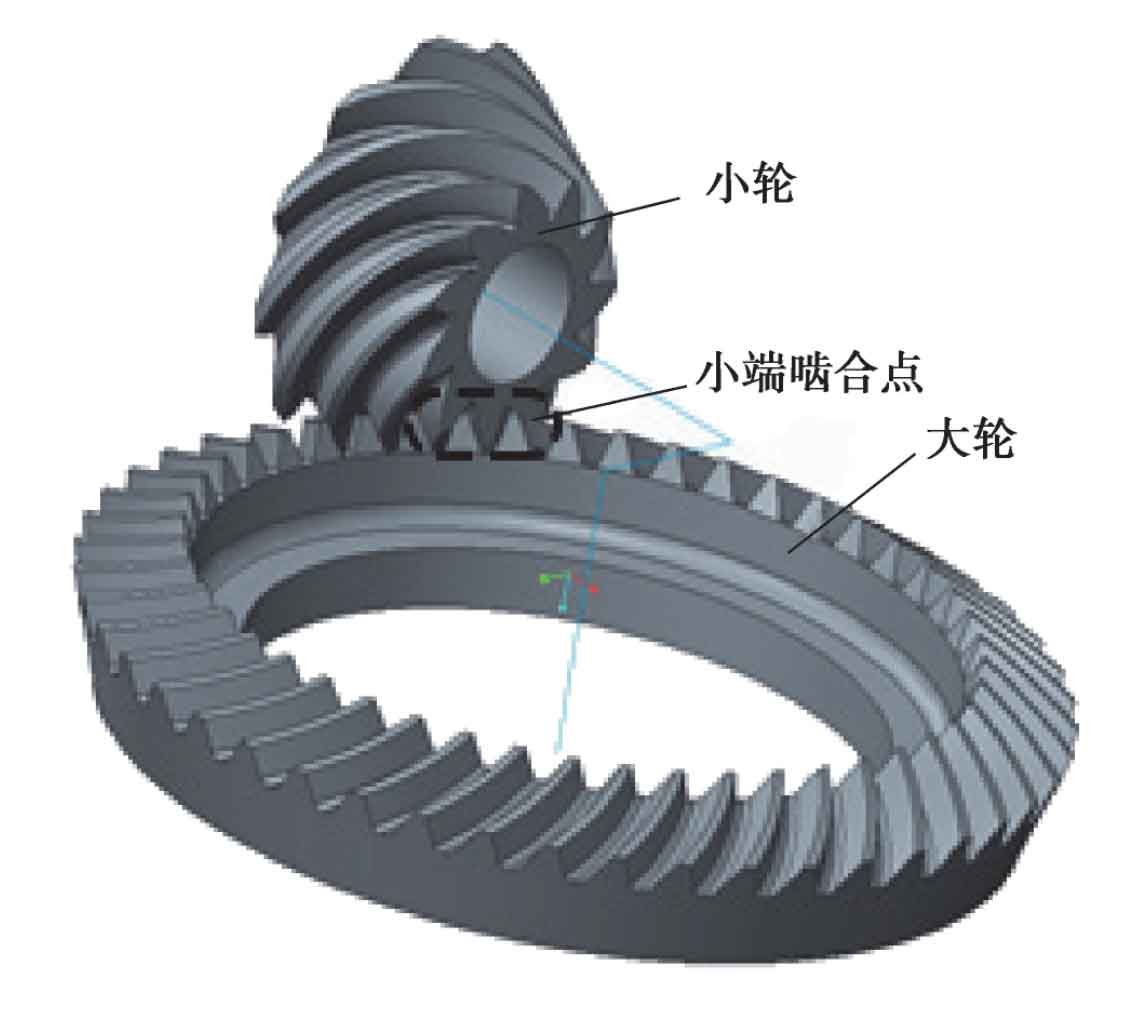

According to the derived mathematical equation of tooth surface and the parameters in Table 1 and table 2, the tool cutting path surface in the blank coordinate system is obtained; The rough of large and small gears is established by Creo, and the track surface of concave and convex surfaces is obtained by boundary mixing. The solid model of large and small gears is obtained by Boolean solution to remove the alveolar material; The hypoid gear meshing entity assembly model is obtained according to the installation parameters, as shown in the figure.

| Parameters | Knife angle i/ (°) | Knife angle j/ (°) | Radial tool position SR/mm | Initial shaking table angle q/ (°) | Vertical wheel position Em/mm | Bed B / mm | Horizontal wheel position A/mm | Root cone angle of machine tool γ/ (°) | Roll ratio Ra |

| Hypoid gear pinion | 3.3325 | 146.9405 | 119.6391 | 52.6673 | 39.8352 | -12.2486 | 3.1156 | 23.4453 | 4.722168 |

| Hypoid gear wheel | 0.0000 | 0.0000 | 122.0090 | -29.7048 | 0.0000 | 0.0000 | 0.0000 | 64.7995 | 0.000000 |

It is the accurate mathematical modeling process of the meshing solid model of Oricon hypoid gear, which is mainly divided into two parts: the establishment of the mathematical model of Oricon gear tooth surface and the three-dimensional solid modeling of hypoid gear. The first part is mainly based on the tool reference datum, starting from the machining of gears, establishes the coordinate system of cutter head, cutter head, machine tool and blank machining, and deduces the mathematical model of gear cutting surface of large and small wheels; Through MATLAB programming calculation, the cutting tooth surface point set of large and small wheels is obtained. In the second part, the obtained tooth surface point set is imported into the three-dimensional design software cero, and the tool cutting path surface, the tool cutting groove and the gear processing blank are obtained by boundary mixing; The full tooth cutting slots are obtained through the annular array, and the solid model of the large and small wheels is obtained through Boolean difference; According to the gear assembly parameters, the meshing solid model of Oricon hypoid gear is obtained.