Die tooth profile design is the key to the precision forging die design of spiral bevel gear. The basic basis of die tooth profile design is the relationship between die tooth profile and cold forging, and the influencing factors that determine this relationship. Generally speaking, the influence of thermal factors is mainly considered when designing die tooth profile.

| Temperature range (℃) | 20-300 | 20-400 | 20-600 | 20-700 | 20-900 | 20-1100 |

| Coefficient of linear expansion | 12.4 | 13 | 13.6 | 14.4 | 16.6 | 18 |

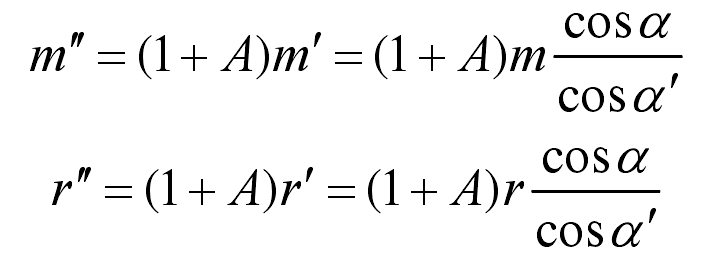

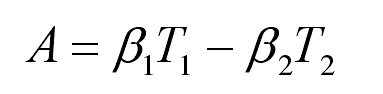

If only considering the influence of thermal factors, it is considered that there is a uniform temperature field in the spiral bevel gear forging and die, the equivalent linear expansion rate a can be calculated by the following formula:

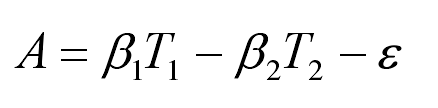

After considering the influence of elastic factors, the formula is updated as:

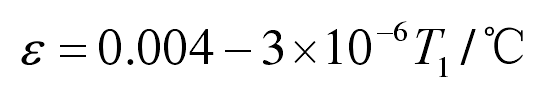

For steel materials, equivalent elastic strain ε It can be calculated according to the following formula:

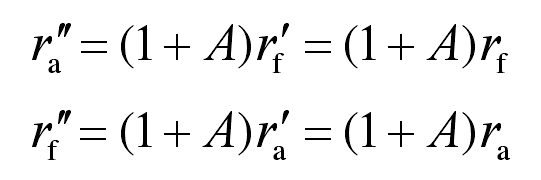

According to the involute tooth profile expansion theorem, the curve after involute tooth profile expansion is still involute, and its length parameters such as base circle radius and indexing circle radius change in equal proportion according to the linear expansion rate. The pressure angle and sub cone angle of the corresponding point of spiral bevel gear profile remain unchanged. Therefore, the angle parameters of the die tooth profile are the corresponding forging tooth profile parameters, which do not need to be calculated. The length parameters of the die tooth profile are calculated as follows: