Single tooth pitch error

Single tooth pitch error refers to the arc length dimension deviation of two adjacent teeth on the indexing circle, which is within a pitch angle of the gear, and has a great impact on the transmission stability accuracy. In the actual gear cutting process, due to the accumulation of indexing error, the single tooth pitch error is often too large, as shown in Figure 1.

Cumulative pitch error

The cumulative pitch error refers to the cumulative result of single tooth pitch error in the circumferential direction. It refers to the error within one cycle of gear rotation, which has a great impact on the motion accuracy. In the actual machining process, the accumulated pitch error is mainly caused by the positioning of tooling, such as eccentricity. As a result, the cumulative error of pitch appears as the fluctuation of quasi sinusoidal function, as shown in Fig. 2.

Tooth profile error

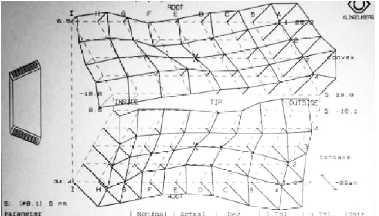

Tooth profile error refers to the deviation of actual tooth profile from theoretical tooth profile, which is mainly caused by tool wear, tooling accuracy, machine feed accuracy and heat treatment deformation during gear processing. The profile error of cylindrical gear is controlled by two dimensions of tooth profile and tooth direction. For the gear of axle main reducer, the evaluation is mainly based on the topological error of tooth surface, as shown in Fig. 3.

Bump

Bumping refers to the impact between the tooth surface and hard object due to improper operation in the production process, resulting in local protrusion or pit on the tooth surface.