In general, undercutting will not occur in the large wheel of hypoid gear with small number of teeth and large reduction ratio, but undercutting may also occur due to negative displacement xhm2 = – xhm1. The method of undercut inspection for aligning the hypoid gear wheel is as follows.

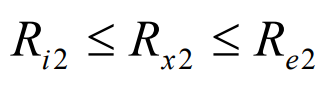

The cone distance rx2 of the inspection point of the large wheel of hypoid gear is determined by the following formula:

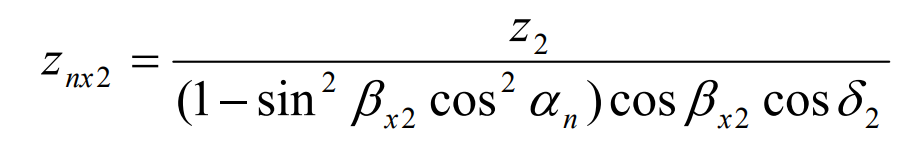

The median value znx1 is:

In order to further select a smaller effective pressure angle, the following formula holds:

When α nC< α Nd, yes α eminx= α nC; When α nC≥ α At nd, α eminx= α nD。

Determine the maximum height deflection coefficient of the calculation point of the hypoid gear pinion:

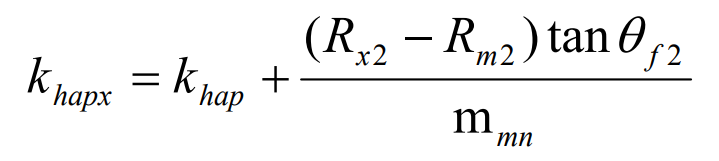

The tool tooth height khapx of the inspection point is:

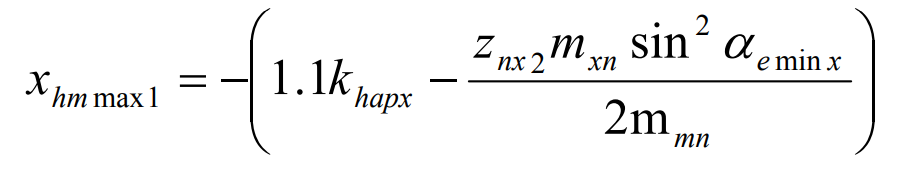

The maximum height modification coefficient xhmmax1 of hypoid gear pinion is:

At this time, if xhm1 > xhmmax1, the hypoid gear wheel will not undercut.

In order to check whether undercutting will occur in the large wheel of hypoid gear with small number of teeth and large reduction ratio, take the cone distance rx2 = 35 of the inspection point. In the calculation example, the tooth top height coefficient and tooth height coefficient of hypoid gear small wheel are 0.05 and 3.5 respectively. After calculation, xhm1 = 1.53 and xhmmax1 = 1.26, that is, xhm1 > xhmax1. Therefore, The designed hypoid gear wheel meets the above conditions without undercutting.