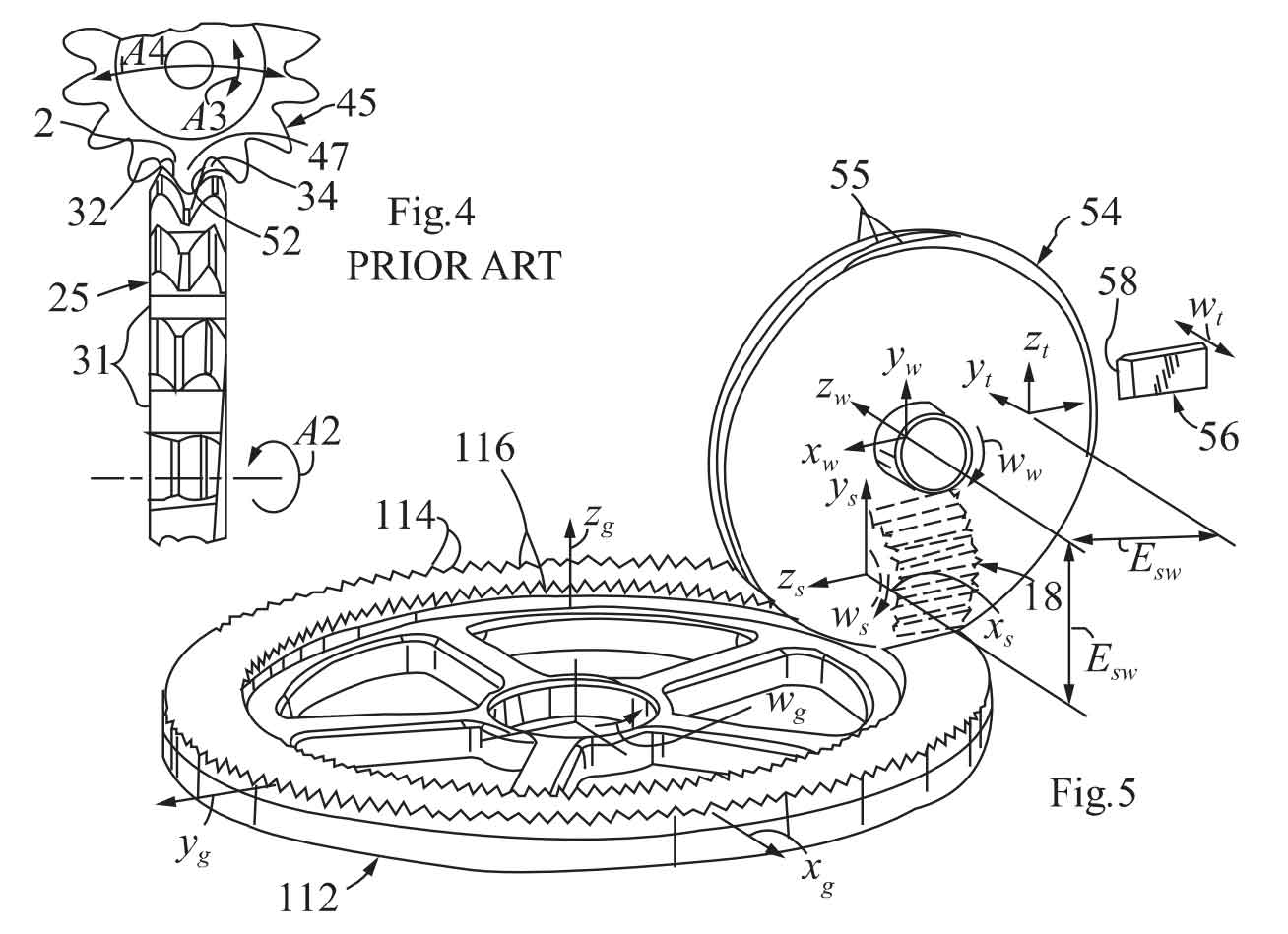

Due to the low efficiency and accuracy of gear shaping and can only cut soft tooth surface gears, which is not conducive to the high-speed and heavy-duty application of surface gears. With the support of NASA, the military and Boeing, Litvin et al. Proposed the method of hobbing (grinding) surface gears with worm hobs (grinding wheels). The principle of this processing method is shown in Figure 3. It is necessary to define the profile line of the worm tool (Fig. 4 in the figure) with the tooth profile of the gear shaper cutter (commonly known as the profile wheel at this time). The tool makes tooth feed movement along the axial direction of the profile wheel (dotted line in Fig. 5 in the figure), which can simulate the axial (longitudinal) tooth profile of the profile wheel, Because the normal section of the forming wheel spirals around the worm axis to form the forming surface of the tool, the rotation of the worm tool around its own axis can simulate the rotation of the forming wheel, and the workpiece rotates around its own axis, so as to realize the meshing between the worm tool and the face gear, and simulate the meshing between the forming wheel and the machined face gear.

The workpiece and worm tool are in point contact, which belongs to double parameter envelope, but due to continuous indexing, the machining efficiency is high. On the one hand, it is necessary to simulate the meshing process between the production wheel and the face gear. Even if it is hobbing, the machine tool is relatively complex. In case of gear grinding, because the tool needs to be trimmed in the machining process, the tool can be trimmed with face gear profile, small wheel profile, plane profile, etc. among them, because it needs to develop into motion in the trimming, it is the most complex to trim the tool with plane profile, which increases the complexity of machine tool and operation again.

Based on this manufacturing technology, foreign scholars have done extensive and detailed research, such as meshing worm tool design, avoiding tool singularity, tooth surface modification and stress analysis, durability test and so on, which has created a good theoretical basis for the practical application of this machining technology. China has also made great progress in the technology of worm tool machining face gear. For example, Wang Yanzhong, Zhao Ning, Zhu Rupeng and Shi Zhaoyao have made outstanding contributions in worm tool design, tooth surface generation, machining experiment and detection.

Worm tools are mainly used in foreign countries for rough cutting and fine grinding of gears. However, this is a typical high-precision technology, and the machine tool, motion and control system involved are very complex. Only a few foreign enterprise groups such as Boeing, NASA and Beixing master it. For example, the second generation worm grinding wheel face gear grinding machine developed by Beixing company, including NC and manual adjustment of generation, tool dressing and error compensation, has as many as 13 moving shafts. It is undoubtedly very challenging to accurately control so much motion to manufacture face gear. At the same time, it also makes the manufacturing cost of face gear extremely expensive. The application of worm cutting tool to cut and grind high-precision face gear promotes the practical and important application of face gear, such as the face gear shunt confluence transmission system on Apache helicopter. However, limited by China’s current equipment manufacturing level, the technology of worm tool machining face gear, especially the gear grinding technology, there are still some difficulties in developing high-precision gear grinding machine based on worm tool in a short time, and it is still difficult to popularize on a large scale.