Firstly, this article calculates the geometric parameters of meshing cylindrical spur gears through the transmission calculation of highly modified cylindrical spur gears, and uses UG (CAD) software to achieve three-dimensional modeling of meshing cylindrical spur gears, providing solutions for the design and further optimization of similar mechanical products.

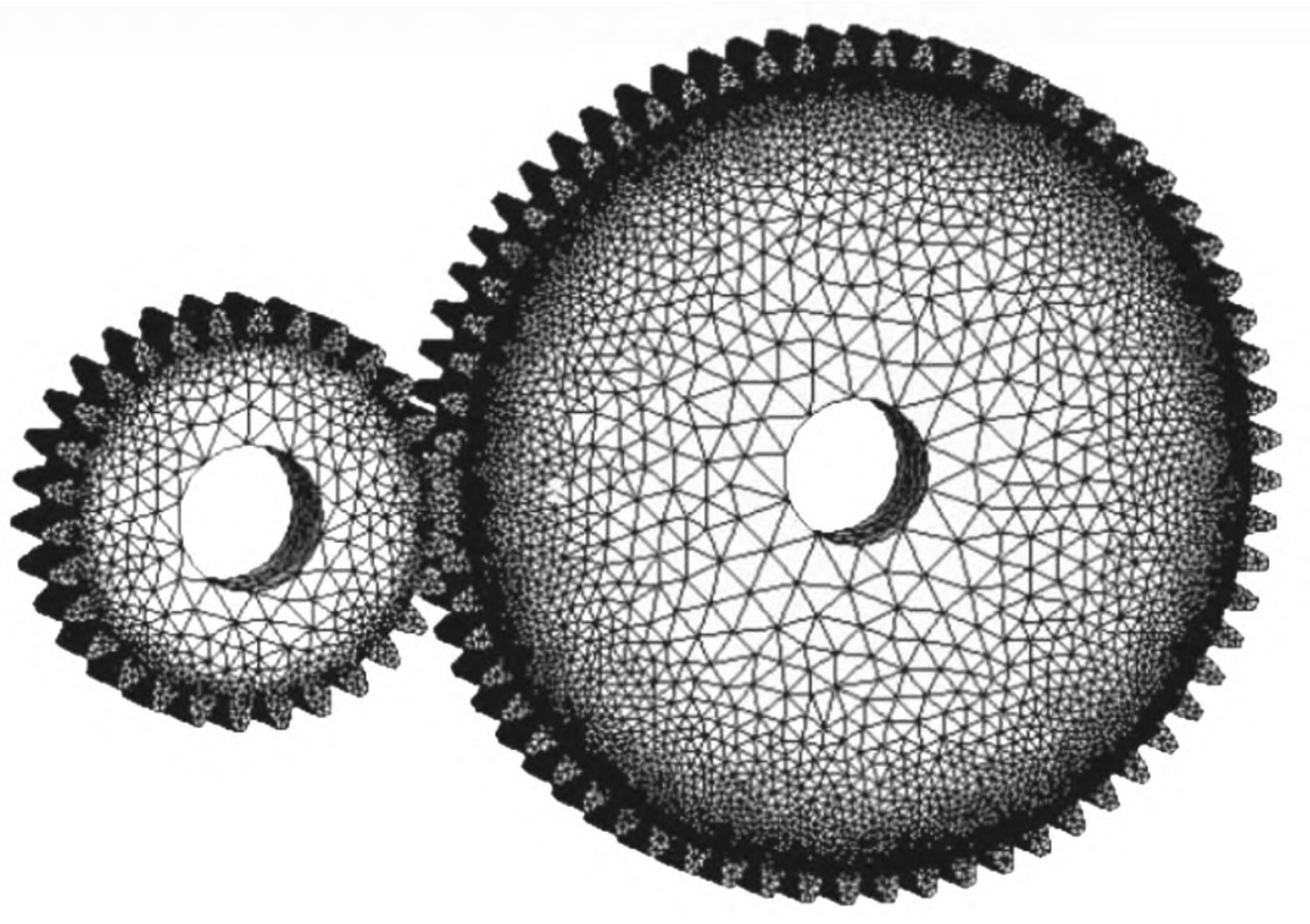

Secondly, the transient dynamics analysis of cylindrical spur gears was conducted using AnsysWorkbench. By assigning materials, 3D mesh partitioning, setting loads and constraints, the stress and displacement cloud maps of the meshing cylindrical spur gears were finally solved, and the force situation during the operation of the cylindrical spur gears was obtained very intuitively.

Thirdly, using the Hertz formula and combining the geometric parameters of the cylindrical spur gear, the theoretical contact stress value of the cylindrical spur gear is calculated and compared with the maximum equivalent stress obtained during the simulation process. The error is small and meets the requirements of the working conditions. Therefore, using UG (CAD) three-dimensional parametric modeling can meet the dynamic characteristics requirements of meshing transmission of highly modified cylindrical spur gears, thereby reducing the cost of product development and shortening the design cycle.