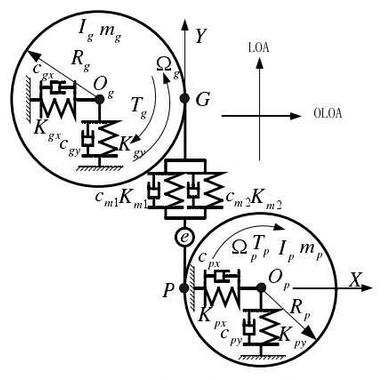

In order to study the comprehensive influence of meshing force and friction force on tooth surface, a simplified dynamic model of Figure 2.2 system is established by using centralized parameter method. The model has six degrees of freedom for translation of active and passive gears in X and Y directions and rotation around their respective axes as shown in the figure.

Km I (tmi (t), CMI (t), CMI (tmi (t) (i=1, 2) is the first I in the Km diagram.For meshing stiffness and damping coefficient of gear, meshing stiffness and damping coefficient change with meshing position; both Kp and damping coefficient change with meshing position; Kpx, px, Kpy, py, Kg, Kgx, gx, Kgy and Kgy are support stiffness of main and passive gear bearings respectively; CPX bearing stiffness, cpx, px, cpy, cpy, py, cgx, gx, cGy and cGy are corresponding damping..E(t) is the gear error defined as follows:

Re is the combination of manufacturing errors such as pressure angle error and pitch error of gear, which is related to gear manufacturing accuracy, eSavg is related, Savge is the error caused by gear surface fluctuation, surface roughness and friction and wear are related, _is the initial phase, P is the number of teeth.

In the direction of engagement line (LOA), the dynamic relative displacement difference between P and G points in active and passive gears is defined as the dynamic transmission error: