1. Analysis of cold shaping process scheme

The cold extrusion die after multi-objective optimization is used for production, and the cold extruded spur gear is detected on the spur gear detection center. The two important indexes of spur gear accuracy detection are the total deviation of tooth profile and the total deviation of helix. Randomly select a formed spur gear for measurement, and detect the total tooth profile deviation and helix deviation of the left and right tooth surfaces of the three teeth selected at the approximate trisection position along the circumference of the spur gear. The accuracy of tooth profile is between 7 ~ 8 levels, while the accuracy of tooth direction is poor, between 9 ~ 10 levels. Therefore, the accuracy of cold extruded spur gear is between 10 levels, which fails to meet the accuracy requirements of Grade 8 spur gear specified in GB / t10095-2001. Therefore, it is necessary to increase the cold shaping process to improve the accuracy of cold extruded spur gears.

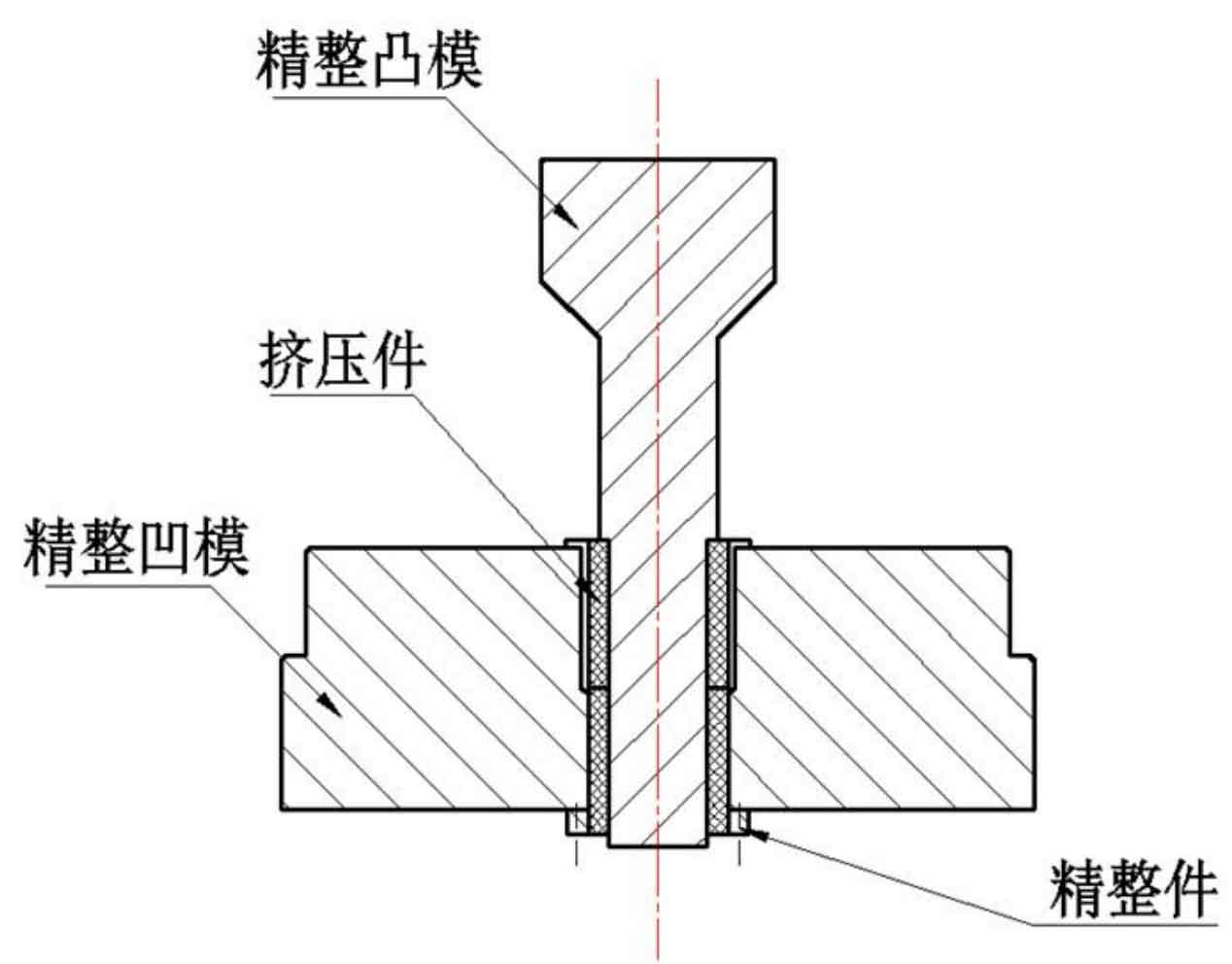

Figure 1 shows the cold shaping process diagram of spur gear. The cold extruded spur gear is put into the shaping die, and the workpiece passes through the shaping die in the form of continuous extrusion. The cold extrusion tooth profile die optimized in the previous chapter is adopted. The cold extrusion straight tooth cylindrical gear has a collapse angle of about 2mm at the upper and lower ends, and the maximum collapse angle is 0.29mm. The tooth top of the extruded straight tooth cylindrical gear can meet the design size requirements after external circle or full tooth cold shaping. Because the accuracy requirement of the tooth root is not high, it can meet the service requirements after cold extrusion. Therefore, the cold shaping of large module spur gear is mainly the shaping of tooth surface.

2. Cold shaping method

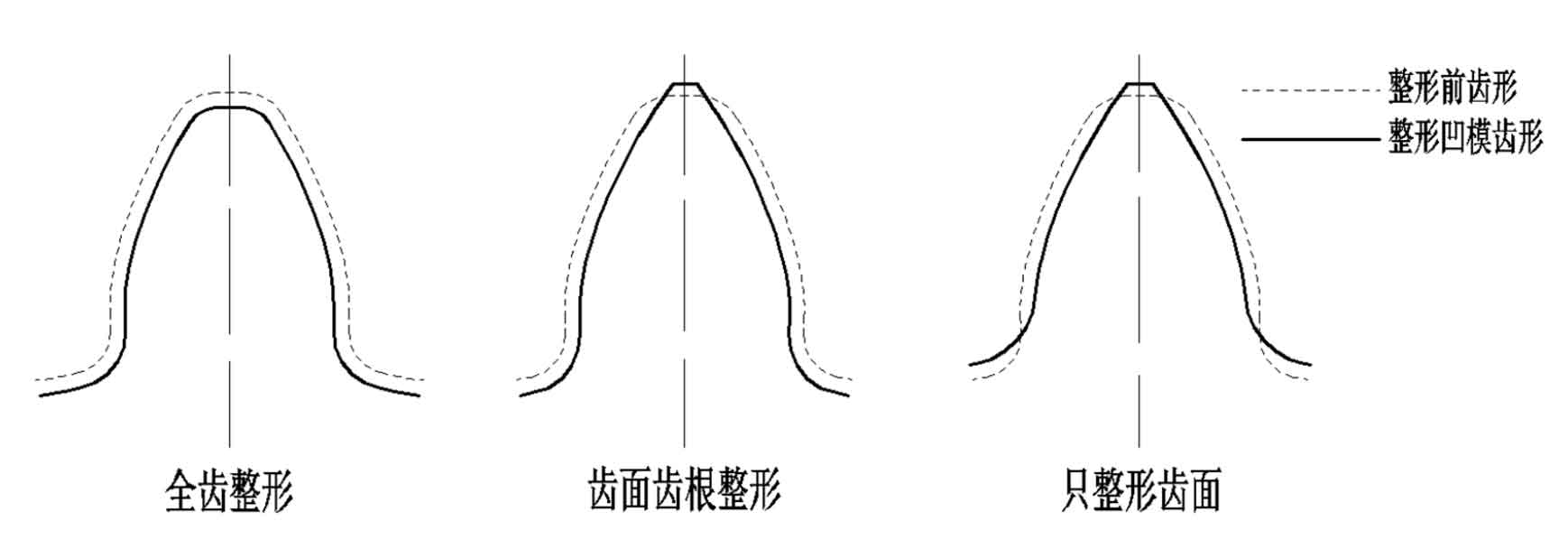

According to the accuracy requirements of large module spur gear, three cold shaping methods are designed as shown in Figure 2, which are full tooth shaping, tooth surface root shaping and only tooth surface shaping. Full tooth shaping is to reshape the tooth top, tooth surface and tooth root; The shaping of tooth surface and tooth root is to reshape the tooth surface and tooth root, and the tooth top is completed by subsequent turning; Only shaping the tooth surface is to shape the tooth surface, and give way to the tooth root and tooth top during the design of shaping die.

3. Preliminary determination of shaping quantity

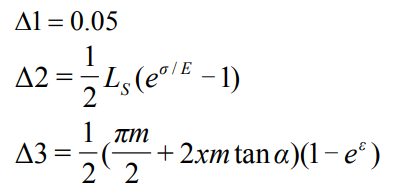

Shaping quantity is one of the important process parameters of cold shaping process, which directly affects the accuracy of straight cylindrical gear after shaping. Taking the cylinder model as an example, the tooth profile deformation of spur gear during cold shaping is studied, and the calculation formula of shaping amount is deduced:

ΔL = Δ1+ Δ2 + Δ3

Where: Δ 1、 Δ 2 and Δ 3 are the unilateral plastic deformation of tooth profile, the unilateral elastic deformation of die and the unilateral springback of spur gear.

Where: LS is the dimension of the die without elastic deformation, mm; σ Is the unit pressure of die, PA; E is the elastic modulus of die material, PA; ε Is the radial strain of spur gear.

The parameters of the straight cylindrical gear studied are substituted into the formula and the results are rounded. In order to make an intuitive comparison with the tooth thickness, the double-sided shaping amount of the straight cylindrical gear is used to explain, and it is concluded that the double-sided shaping amount of the straight cylindrical gear is 0.15mm. Therefore, it is preliminarily determined that the bilateral shaping amount of spur gear is 0.15mm as the standard of numerical simulation.