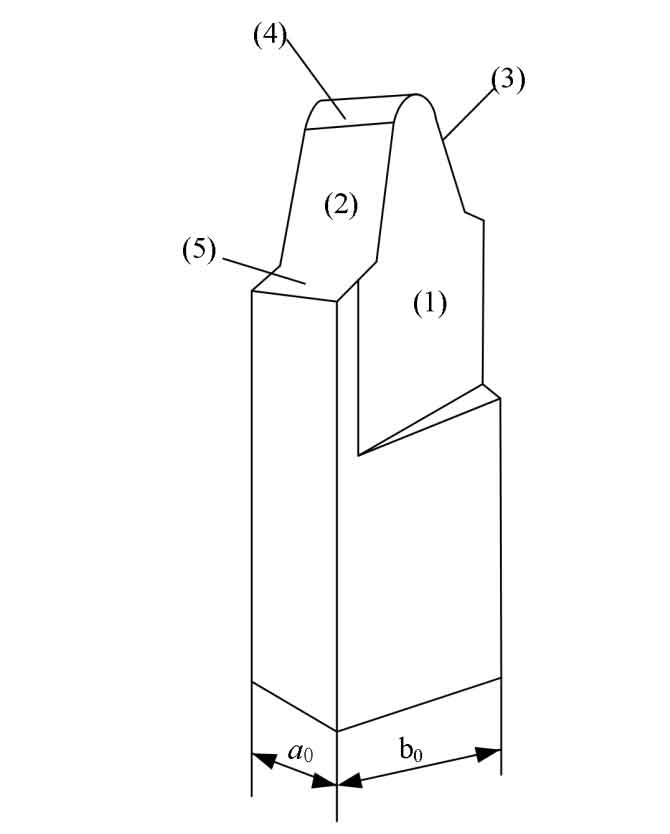

The contour spiral bevel gear milling cutter bar is mostly in the shape of prism, and the cross section in the middle is rectangular. The width B0 of the contour spiral bevel gear milling cutter bar is much greater than the thickness A0 of the cutter bar. The contour of the contour spiral bevel gear milling cutter bar is composed of at least three faces, and the divided parts can be clearly seen from Figure 1.

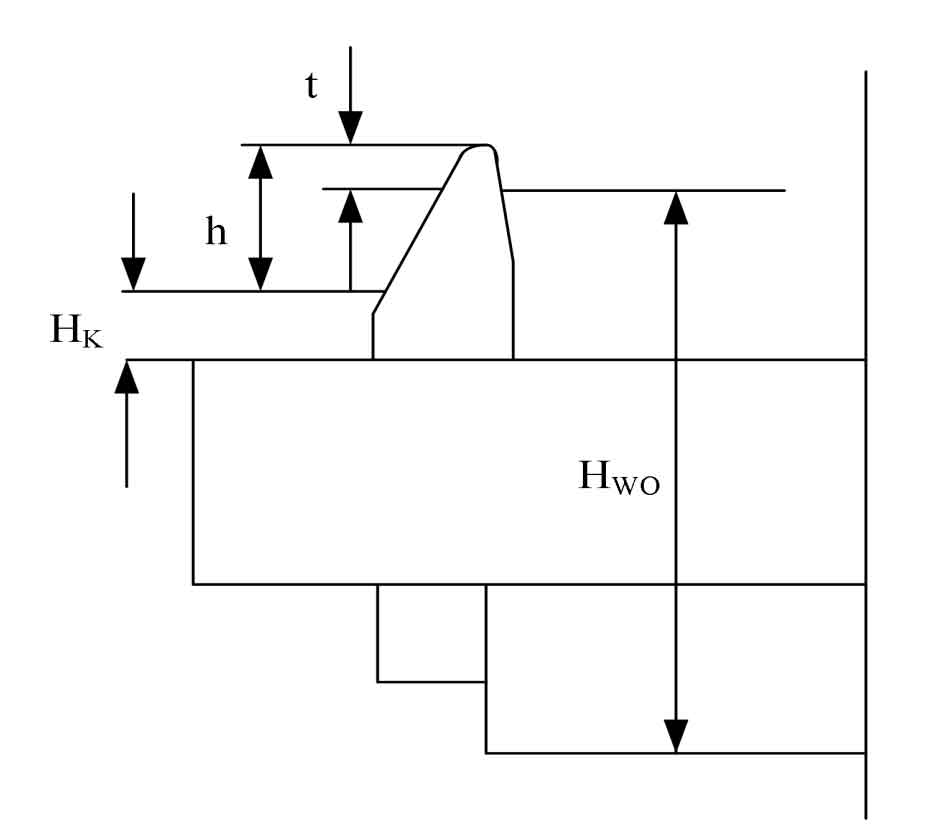

As shown in Figure 2, hwo is the length from the bottom of the cutter head installed on one side of the milling cutter bar of equal height spiral bevel gear to the edge of the milling cutter bar; HK is the installation distance reserved for the convenience of debugging the milling cutter bar of equal height spiral bevel gear; T is the length from the reference point of cutting edge to the tip of contour spiral bevel gear milling cutter; H is the distance of the grinding part of the milling cutter of the spiral bevel gear with equal height teeth.

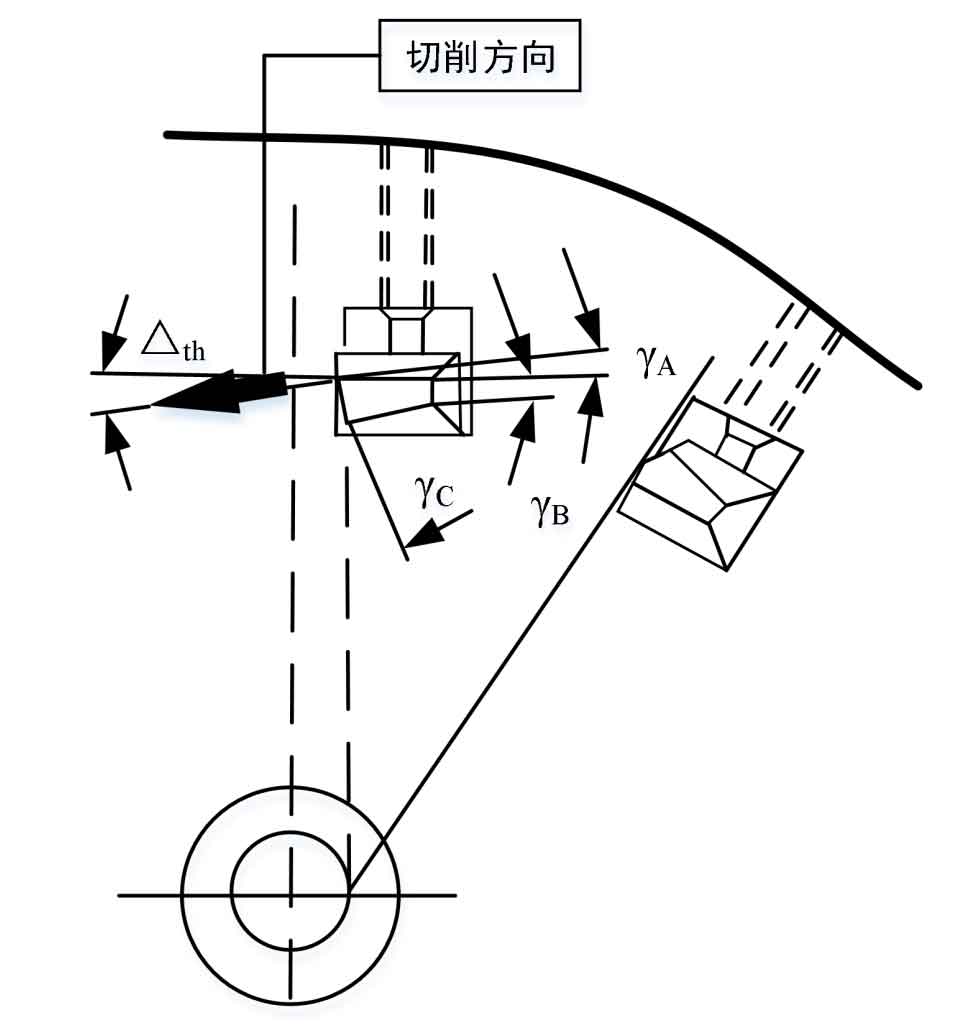

As shown in Figure 3, the motion direction of the contour spiral bevel gear milling cutter is consistent with the rotation direction of the contour spiral bevel gear milling cutter head, and its motion direction is the same as the transverse angle of the contour spiral bevel gear milling cutter bar Δ th ; The rake angle of a tool in machining motion γ c. Back angle of main edge γ A. Back angle of secondary edge γ B 。