Hypoid gear pair is a special bevel gear pair used to transfer staggered axis motion and load. It has the advantages of strong bearing capacity, good meshing performance, compact structure and long service life. It is widely used in the main reducer of vehicles and construction machinery.

A comprehensive subject combining the professional knowledge of hypoid gear with computer application knowledge. Starting with the calculation of geometric parameters of hypoid gear, this paper explores the calculation method of geometric parameters, the establishment of three-dimensional model, parametric system and motion simulation:

- Based on the geometric design idea of Gleason hypoid gear and combined with the optimization design theory, a new geometric parameter calculation method is proposed to improve the calculation accuracy of geometric parameters in theory by setting the termination conditions of the optimization algorithm. Based on the new design method, the geometric design and strength check of hypoid gear pair are completed, and the geometric parameters of master-slave bevel gear are obtained.

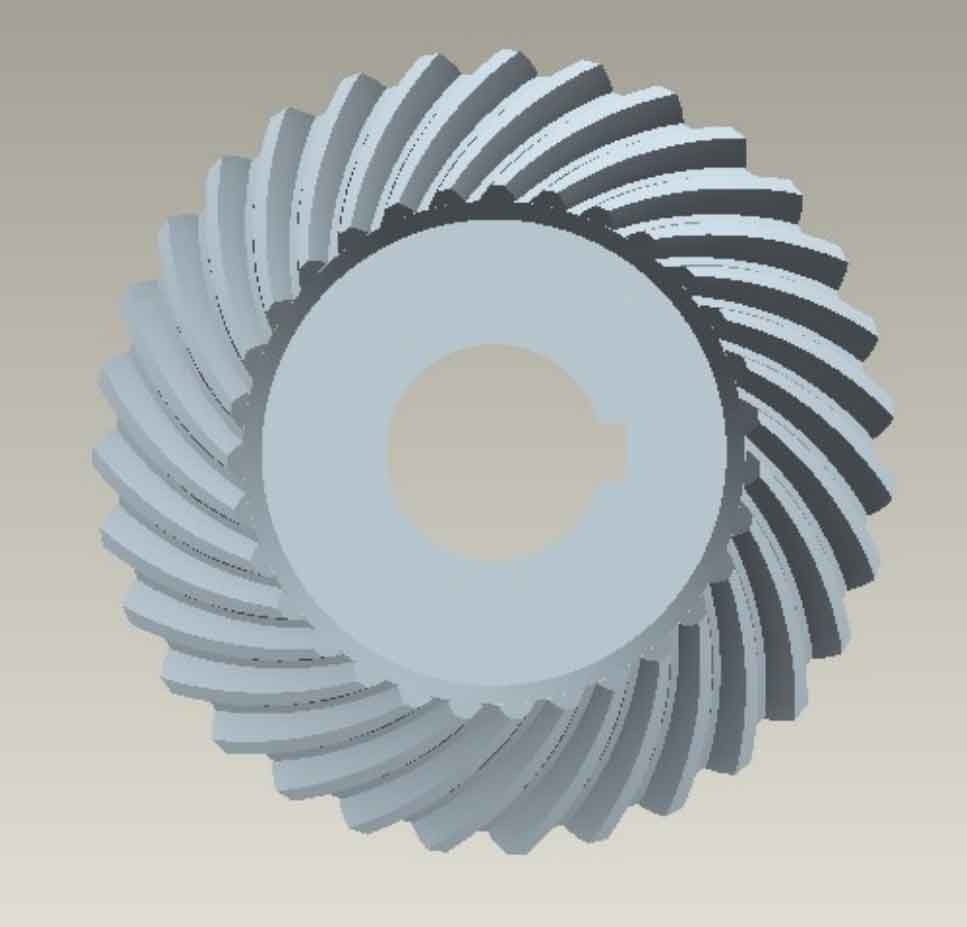

- Based on the spherical involute equation, in Pro / E2 0 software uses the function of generating curve from equation to generate spherical involute to complete the tooth profile of single tooth of hypoid gear pair. Taking visual c + + 6.0 integrated development environment as the development platform, based on the hypoid gear design theory and the principle of parametric design, Pro / E2 is implemented through Pro / Toolkit application program interface 0 software, and the parametric design system of hypoid gear is established.

- Using the mechanism simulation analysis module Pro / mechanism under the Pro / E platform, the motion analysis of the assembled hypoid gear pair mechanism is carried out, the meshing condition and motion interference of the hypoid gear pair are checked, and the speed variation diagram of the hypoid gear at different speeds is obtained, which verifies that the design method is reasonable.