In order to ensure the quality of the experiment, this paper uses the contact area trace based on the concave convex tooth surface of spiral bevel gear to achieve effective verification. The experiment gives the trace trace images of the big gear and the small gear on the concave and convex surfaces respectively. The quality of the visual tracking method in this paper is verified from the images. The experimental results are shown in Fig. 1.

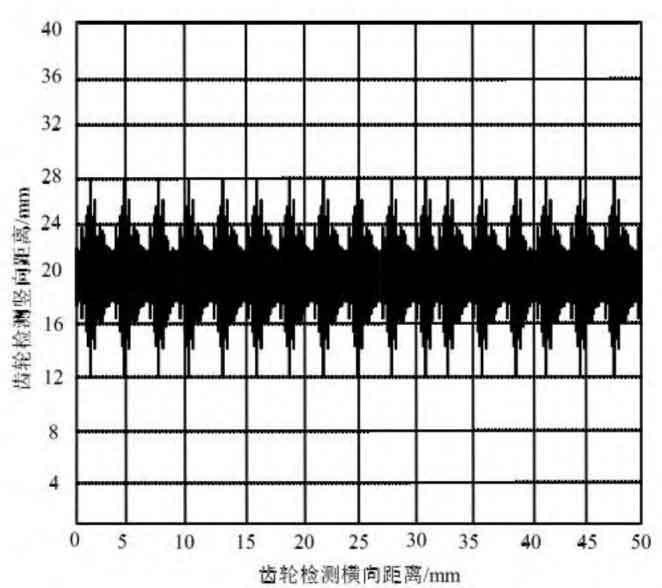

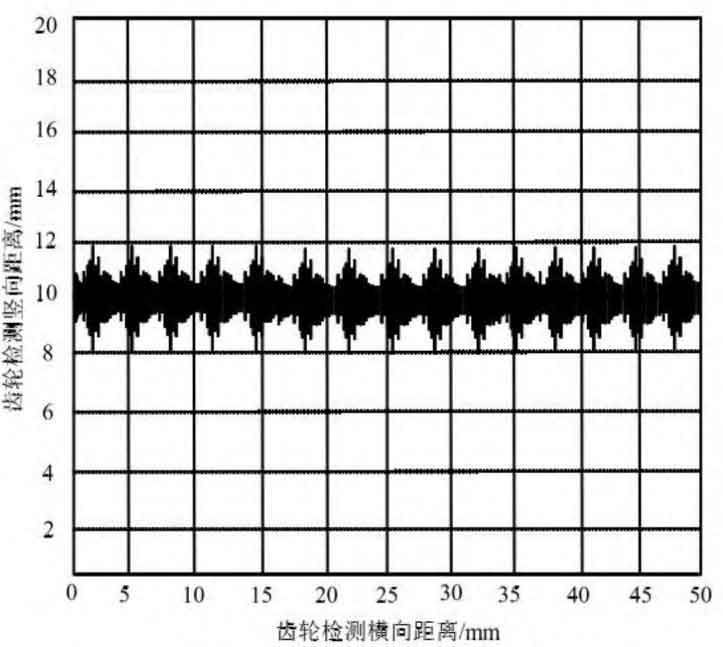

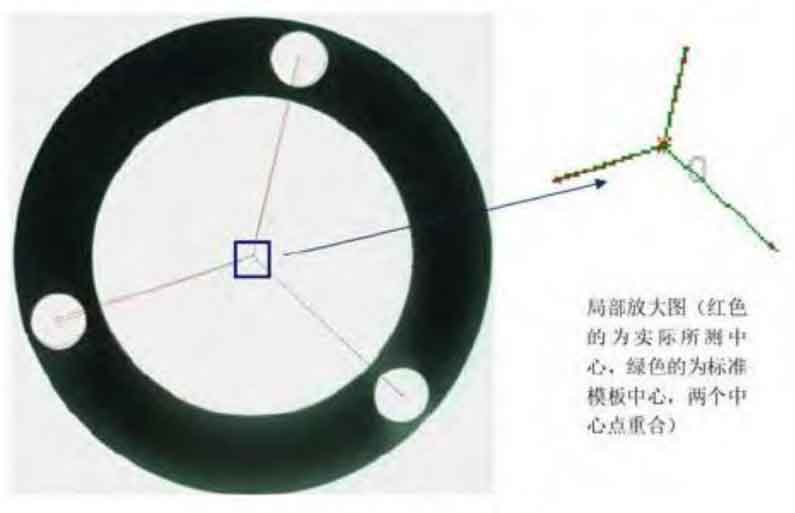

The visual tracking result is signalized, and the result is shown in Fig. 2.

It can be seen from Fig. 2 and Fig. 3 that the trace tracking results of the concave surface of the spiral bevel gear show an irregular motion state, and each concave contact point forms a trace shape with different lengths. It shows that when the motion frequency of spiral bevel gear is high and the rotation speed is high, a large area of meshing surface is generated during the initial contact with the tooth surface, and the center line of the meshing surface is a trace. With the next rotation, the tooth surface and the concave surface of the bevel gear gradually separate, and the trace length becomes shorter. According to the morphological characteristics of the concave surface, when the spiral bevel gear moves, the contact surface trace will be generated infinitely. With the increase of the moving speed, the number of contacts and the contact area, the trace will follow the motion law infinitely and gradually appear a cycle phenomenon. This also explains the phenomenon that the concave surface trace in the figure is relatively scattered. Careful observation of the image also shows that the trace range of the large gear is larger than that of the small gear. This is because the larger contact surface of the spiral bevel gear is, the larger the range of the center line formed at the meshing point is. Through comprehensive comparison, it is found that the experimental results obtained by the visual image tracking method conform to the actual logic and have higher tracking quality.

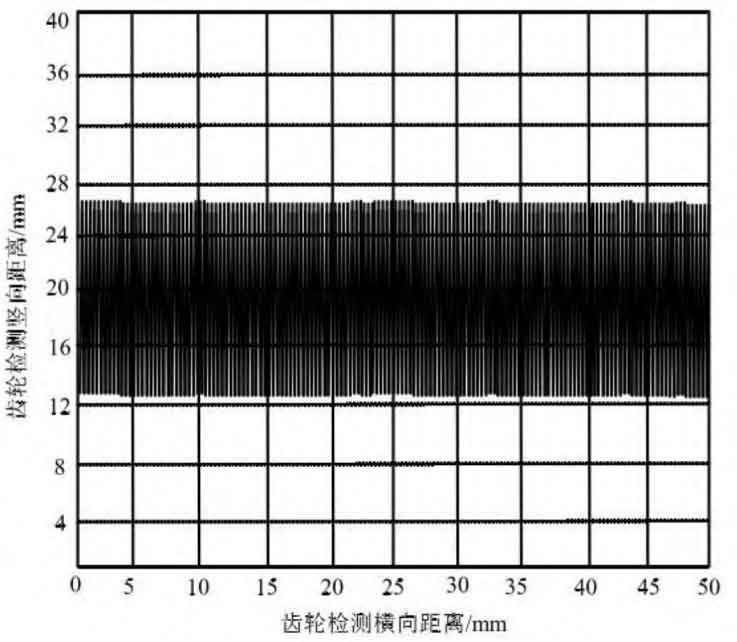

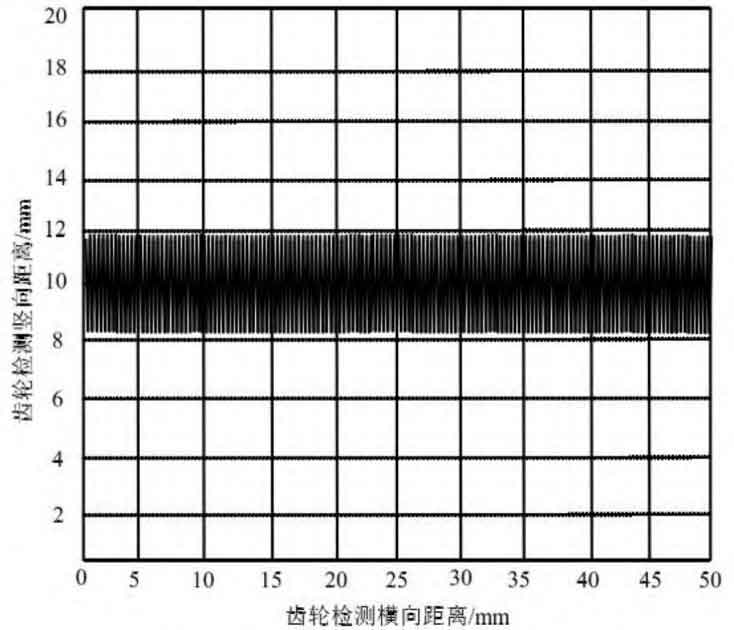

It can be seen from Fig. 4 and Fig. 5 that the trace tracking results of convex surfaces are very different from those of concave surfaces, with large differences. The trace changes of convex surfaces are more regular, and the space between lines is small. The convex surface belongs to a diffusive mechanical form. During the operation of the spiral bevel gear, the convex surface will infinitely expand the contact force between the spiral bevel gear and the tooth surface, so that the contact surface between the two will gradually become smaller and reduced to a minimum stress point. The smaller the point, the smaller the trace. With the operation of the spiral bevel gear, a more concentrated motion range will gradually be formed. Through the comparison of the concave and convex experimental results, the tracking effect of this method is better, which is in line with the actual situation, and the trace tracking results are reasonable and accurate.