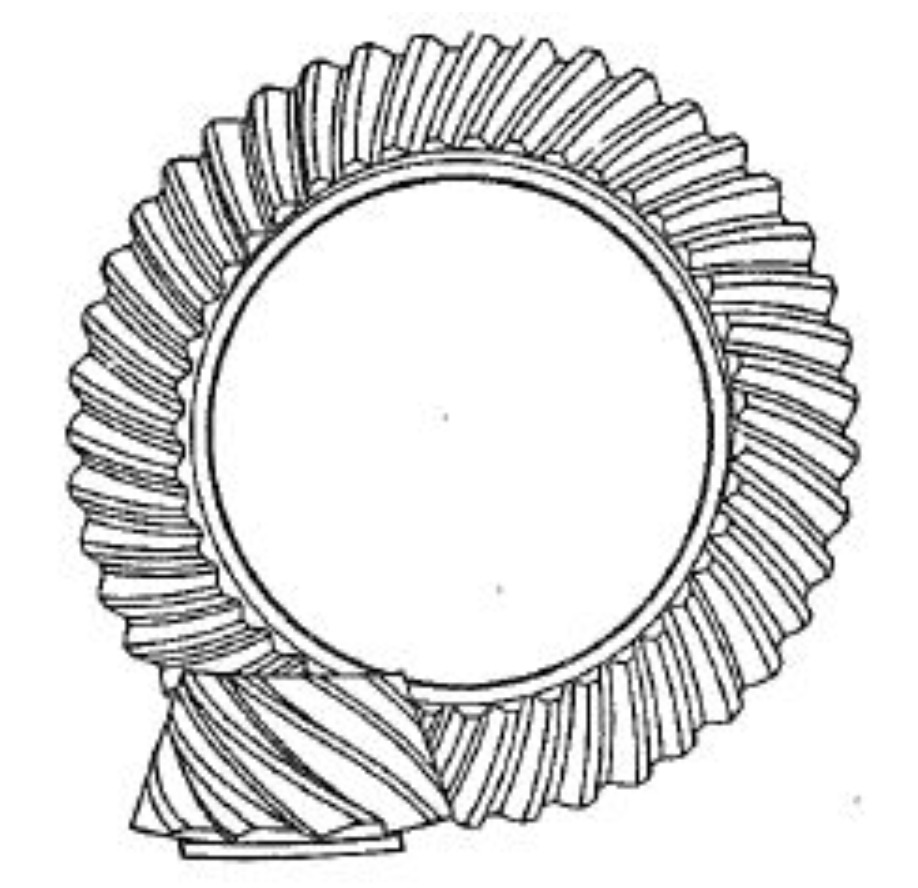

Hypoid gear is an advanced type of bevel gear, commonly used in heavy machinery for enhanced durability and efficient torque transmission. hypoid gear are distinguished by their axes, which do not intersect; instead, the axes are skewed, often resulting in a larger diameter gear engaging with a smaller one.

Advantages in Heavy Machinery:

- Increased Durability: The design of hypoid gear allows for more gradual engagement between the teeth. This gradual engagement reduces the impact stress and distributes the load more evenly across the teeth, leading to increased durability.

- Improved Torque Transmission: Due to the increased surface contact between teeth, hypoid gear can transmit higher levels of torque compared to traditional bevel gear. This is particularly beneficial in heavy machinery where large amounts of power need to be transferred efficiently.

- Lower Noise and Vibration: The tooth engagement in hypoid gear is smoother, which significantly reduces noise and vibration. This is a critical factor in heavy machinery, as it leads to a more comfortable working environment and less wear on other components.

- Compact Design: Hypoid gear allow for more flexibility in design, often resulting in a more compact gear arrangement. This is advantageous in heavy machinery where space and weight are critical factors.

- Improved Differential Gear Design: In automotive applications, hypoid gear are often used in the differential, where they allow for the drive shaft to be offset, leading to improved ground clearance and vehicle design flexibility.

Applications in Heavy Machinery:

- Construction Equipment: Such as excavators, bulldozers, and cranes, where the need for robust and efficient power transmission is paramount.

- Agricultural Machinery: Tractors and combine harvesters benefit from the durable and efficient power transmission of hypoid gear.

- Mining Equipment: In heavy-duty mining applications, the durability and compact design of hypoid gear is extremely beneficial.

Considerations and Challenges:

- Manufacturing Complexity: The production of hypoid gear is more complex than standard bevel gear, requiring specialized equipment and expertise.

- Lubrication Requirements: Hypoid gear demand high-quality lubrication due to their sliding action, which can increase maintenance needs.

- Cost: The complexity in design and manufacturing often translates to a higher cost compared to standard gear.

Conclusion:

Hypoid gear represent a significant advancement in gear technology, offering numerous benefits in heavy machinery applications. Their ability to transmit higher torque, enhanced durability, and reduced noise and vibration, while maintaining a compact design, makes them an invaluable component in many heavy-duty applications. Despite their manufacturing complexity and cost, the advantages they bring to heavy machinery often outweigh these challenges.