This paper focuses on the new type of double-point contact internal meshing gear with curve configuration. It conducts in-depth research on the basic theory of tooth surface forming grinding, the analysis of the forming grinding temperature field, the prediction and parameter optimization of grinding temperature, and the analysis of residual stress under thermal-structural coupling. The research provides theoretical support and technical guidance for the application and development of this new type of gear in the field of mechanical transmission.

1. Introduction

1.1 Research Background and Significance

Gears play a crucial role in mechanical transmission. As a common mechanical transmission component, they ensure the normal operation of various mechanical equipment by transmitting power and torque. Different combinations of gear sizes and teeth numbers can achieve speed adjustment, meeting the needs of different processes and equipment. Moreover, gear transmission is known for its reliability and durability, which is essential for maintaining the continuity and stability of industrial production and promoting its development and progress.

However, traditional involute gears have some limitations. Their manufacturing process is relatively complex, requiring high-precision processing equipment and techniques, resulting in high production costs and being unsuitable for some low-cost applications. Although involute gears can reduce noise and vibration in gear transmission to some extent, they may still generate a certain degree of noise and vibration under high-speed and high-load operating conditions.

Non-involute curve configuration gears, as a new type of gear transmission form, offer several advantages. Their designed tooth profiles can better adapt to working loads, improving transmission efficiency and reducing friction losses. The circular arc-shaped tooth profile design reduces the impact and vibration during meshing, resulting in less noise and vibration during operation, thereby enhancing the smoothness and comfort of the system. The high flexibility of the tooth profile design allows for customization according to different application requirements, making them suitable for various industrial fields and special working conditions. Additionally, they have good load-carrying capacity and durability. Moreover, the design of curve configuration gears can effectively reduce the volume and weight of gears, providing significant advantages in space-constrained or lightweight applications.

Grinding is a precision machining method that can effectively improve the surface quality and accuracy of gears. By reducing the surface roughness of gears and removing surface defects such as burrs and flash, it can achieve a smoother surface. At the same time, grinding enables higher-precision gear processing, ensuring that the gear geometry is more accurate and meets the design requirements. However, during the gear grinding process, the rapid accumulation of grinding heat can easily lead to local overheating, causing burns on the tooth surface. Therefore, it is necessary to explore the changes in the tooth surface forming grinding temperature field under different grinding conditions to effectively reduce the grinding temperature. In addition, the residual stress generated during grinding may have adverse effects on the gear, such as deformation, reduced fatigue life, and compromised surface quality. These issues can be addressed by optimizing grinding parameters, employing appropriate heat treatment and surface treatment methods, and controlling the temperature and cutting speed during the machining process.

To further promote the performance analysis and engineering application of the new curve configuration gears, this paper conducts research on the basic theory of tooth surface forming grinding, the analysis of the forming grinding temperature field, the prediction and parameter optimization of grinding temperature, and the analysis of residual stress under thermal-structural coupling of the new double-point contact internal meshing curve configuration gears. The relevant research provides a theoretical basis for the actual grinding process of curve configuration gears and is of great significance for promoting the application of this new type of gear.

1.2 Research Status at Home and Abroad

1.2.1 Gear Machining Technology

In developed countries, gear machining technology exhibits advanced features in terms of innovation, digitization, intelligence, machining accuracy, and process stability. Foreign scholars have made many innovative contributions in this field. For example, Chen et al. constructed an actual forward kinematics model (FKM) based on the geometric error module to establish the error tooth surface of GE, enabling dynamic compensation of tooth surface machining and improving machining accuracy and efficiency. Kanto Kenta et al. utilized a 5-axis machining center and a laser scanning probe to conduct research on a gear profile measurement system based on automatic correction of measurement results, enhancing gear machining accuracy. Tashiro et al. developed a new tool wear testing method during the hobbing process, using uncoated and TiN-coated high-speed steel tools to investigate the influence of coating on cutting resistance and cutting temperature. Mal’ko L. S. et al. considered the cutting of spherical conjugate surfaces of an initial cylindrical gear and confirmed the feasibility of their method through experimental results, demonstrating that high-load-capacity spherical gears can be manufactured without a ball mill when the hardness difference of the contact surfaces is significant.

In the field of gear finishing in China, scholars have also achieved remarkable results. He Yunpeng proposed a method of rough machining with a finger milling cutter and finish machining with a ball milling cutter to improve the tooth surface machining accuracy of equal-base bevel gears. Chen Wei et al. enhanced the positional accuracy of the internal and external teeth of planetary gears by strictly controlling the parallelism of the end face of the planetary gear, the perpendicularity between the internal teeth and the end face, modifying the hobbing allowance of the external teeth of the semi-finished planetary gear, and calibrating the runout of the end face and circular runout of the planetary gear hobbing tooling. Hu Shanshan et al. optimized the parameters of a two-axis controller using the particle swarm optimization algorithm based on the controller parameters to improve the tooth surface machining accuracy of non-circular gears in CNC hobbing. Wang Zhiyong et al. established a mathematical model of the tooth surface of a straight bevel gear machined by an internal concave cutter head based on the machining principle and structural characteristics of the internal concave cutter head and verified the correctness of the tooth surface mathematical model and the TCA method through gear cutting experiments. Zhang Xincheng et al. derived the tooth surface and tooth root transition surface equations of a face gear and achieved high-precision machining of the face gear through tooth surface error detection using the Gleason 650GMS gear inspection center. Huan Haixiang et al. conducted cutting simulation research on high-strength medium-alloy carburized steel gear thin webs and analyzed the results using range analysis to predict and optimize the cutting parameters. Zong Zifan designed an auxiliary support device and established a finite element prediction model to analyze the deformation law of gears during hobbing and effectively control the deformation during hobbing of cycloidal gears. Wang Shaojie et al. established a mathematical model of the tooth surface of an internal gear honing wheel to solve the honing wheel tooth surface equation. Based on previous research, they proposed to continuously adjust the additional radial movement of the honing wheel during the axial movement of the honing wheel and verified the effectiveness of multi-axis linkage in gear modification machining through simulation. Guo Erkuo et al. established a mathematical model of cylindrical gear shaving based on the theory of crossed-axis gear transmission and proposed a compensation method for tooth profile error, which effectively improved gear machining accuracy.

1.2.2 Gear Form Grinding Technology

Gear grinding technology is continuously evolving both domestically and internationally. Domestic enterprises have made significant progress in improving equipment and processes through technological advancements and market competition to meet the growing demand. In developed countries, they lead in automation, intelligence, and research and innovation, serving the global market and maintaining a competitive edge. Overall, gear grinding technology is advancing globally to meet the market’s demand for high-quality and efficient gear products. However, the technology still faces challenges such as improving machining efficiency, reducing costs, enhancing accuracy and surface quality, adapting to new materials, optimizing lubrication, addressing environmental and energy consumption issues, and promoting digitalization and intelligence. Overcoming these challenges requires the joint efforts of the industry to drive continuous improvement and innovation in gear grinding technology.

To improve gear grinding accuracy, it is crucial to select high-quality equipment, optimize machining processes, enhance operator skills, conduct precise measurement and inspection, establish a quality control system, and continuously pursue improvement and innovation. Zhang Xuecheng et al. proposed a new worm gear transmission method with linear tooth surface contact and a principle and method for grinding cylindrical gears without axial feed using this worm as a grinding wheel. Yang Hui et al. established a mathematical model for tooth profile modification in form grinding, solved the instantaneous contact line between the grinding wheel and the gear, analyzed the influence of the grinding wheel radius and installation angle on the form grinding contact line, and proposed three compensation methods for tooth profile modification distortion errors. Yu et al. presented a new method of MACLA envelope grinding using an ultra-thin diamond grinding wheel with a high-order curve section profile to directly compensate for dressing errors. They also established a mathematical model of the grinding wheel with a high-order curve section profile and a grinding wheel path model. Ding Guolong et al. obtained the complete grinding wheel profile for grinding a tooth slot using the non-instantaneous envelope method and derived the analytical expressions of the left and right fixed chord tooth points. They optimized the grinding wheel profile by changing the shape and position of the contact line between the grinding wheel and the gear. Huang Shuaike et al. solved the grinding wheel profile based on the Simpson numerical differentiation method, combined with the accumulative chord length parameter cubic curve method and the Newton iteration method, and compared it with the grinding wheel profile solved by the local cubic B-spline fitting method. Zhao Yi et al. established a coordinate system based on the form grinding principle and obtained the final axial profile of the grinding wheel through spatial coordinate transformation using the tooth surface equation of the four-arc gear and the contact conditions between the gear tooth surface and the grinding surface of the form grinding wheel. Vilmos V. Simon proposed a new method for grinding hypoid gears using generating and Waguri motions and studied the influence of abrasive size and motion relationships during grinding on the surface roughness of the ground tooth surface. Sheng Bin et al. established a calculation model for the surface roughness of gears ground along the contact line based on the analysis of the machining trajectory of the butterfly-shaped grinding wheel and verified through experiments that contact deformation is the main factor affecting grinding accuracy. Wang Jiong et al. established a geometric error model for tooth profile and helix modification in form grinding, solved the form grinding contact line, calculated the geometric error in form grinding, and provided suggestions for reducing the error.

1.2.3 Research on Gear Form Grinding Temperature

There has been extensive research on grinding temperature fields both domestically and internationally. W. B. Rowe proposed a deep grinding thermal model particularly relevant to the HEDG process and experimentally confirmed that HEDG can achieve lower specific grinding energy compared to shallow grinding and generating grinding. Yan Hongzhi et al. established a 3D finite element model of the grinding temperature field of gears using the heat conduction and rectangular moving heat source theory and the finite element method and analyzed the transient temperature field of gear grinding. Li Guolong et al. simulated the temperature field of involute gears made of 45# steel ground by a large plane grinding wheel using ANSYS software and numerically calculated the grinding temperature using MATLAB software. They compared the simulation and calculation results and found that the variation of the grinding temperature along the tooth width direction was consistent. Yang et al. established a new temperature model based on the moving heat source distribution of a high-order function curve in the grinding zone and compared the results. They found that the highest temperature heat source based on the high-order function curve appeared earlier and closer to the front of the grinding contact arc compared to the triangular and rectangular heat source distribution shapes. Su Jianxin et al. simulated the change in tooth surface temperature under different grinding conditions using ANSYS based on the involute gear grinding model and compared the simulation results with grinding experiments. They found that the use of grinding fluid, large feed speed, high grinding wheel speed, and small grinding depth could effectively reduce the maximum tooth surface temperature and avoid tooth surface burns. Yi Jun et al. proposed a heat source distribution model for involute gears based on the right triangle heat source theory and found through grinding experiments that the rolling angle affected the distribution of the grinding temperature along the involute gear tooth surface. Gao et al. studied the relationship between the grinding wheel-workpiece contact geometry, the local material removal mode in the grinding zone, and the grinding temperature distribution. They established a comprehensive three-dimensional analytical thermal model considering the grinding wheel-workpiece contact geometry and its influence on the grinding heat flux distribution and verified the model through experiments. Pang et al. proposed a Weibull heat flux distribution model for predicting the temperature in dry and wet grinding and calculated the workpiece surface temperature distribution using the experimental heat flux obtained by the inverse algorithm. They also analyzed the error between the calculated temperature and the experimental temperature. To prevent the occurrence of thermal damage, Ke Qingxun et al. numerically simulated the distribution of the tooth surface temperature field under different gear grinding process parameters in the wet grinding condition. They calculated the heat distribution ratio and convection heat transfer coefficient during the grinding process using theoretical analysis and simulated the distribution of the tooth surface temperature field in the wet grinding condition using the finite element method and computer simulation software. Ma Zhanlong et al. simulated the distribution of the grinding temperature field using the finite element method and verified the accuracy of the simulation results through experiments. Subsequently, they used the simulation results as training samples to predict the grinding temperature under different conditions using a BP neural network and verified the accuracy of the BP neural network prediction model by comparing it with the simulation results. Jiang Tianyi et al. established an improved error backpropagation (BP) neural network based on the good nonlinear approximation characteristics of the artificial neural network using the orthogonal experimental results as the training samples of the neural network. They minimized the network error using the Levenberg-Marquardt algorithm and optimized the combination of the sum of squared network weights and thresholds using Bayesian regularization. Sun Weizhao et al. obtained the grinding temperature data through simulation, wrote a convolutional neural network program using the Google open-source deep learning tool TensorFlow, and compared the prediction results with the simulation values. The results showed that the grinding temperature prediction model based on the convolutional neural network had strong learning ability and nonlinear fitting ability, significantly improving the grinding temperature prediction accuracy.

1.2.4 Research on Grinding Force-Thermal Coupling

The grinding force-thermal coupling phenomenon in gear grinding refers to the mutual influence and coupling relationship between the mechanical cutting force and thermal effects (including temperature distribution and thermal deformation) during the grinding process. This research area encompasses the thermomechanical behavior of materials during grinding and is of great significance for improving grinding efficiency, enhancing the surface quality of parts, and Research on Tooth Profile Grinding Method and Temperature Field Analysis of Internal Meshing Gear with Curve Configuration.

2. Basic Theory of Tooth Surface Forming Grinding for Double-Point Contact Internal Meshing Curve Configuration Gear

2.1 Overview

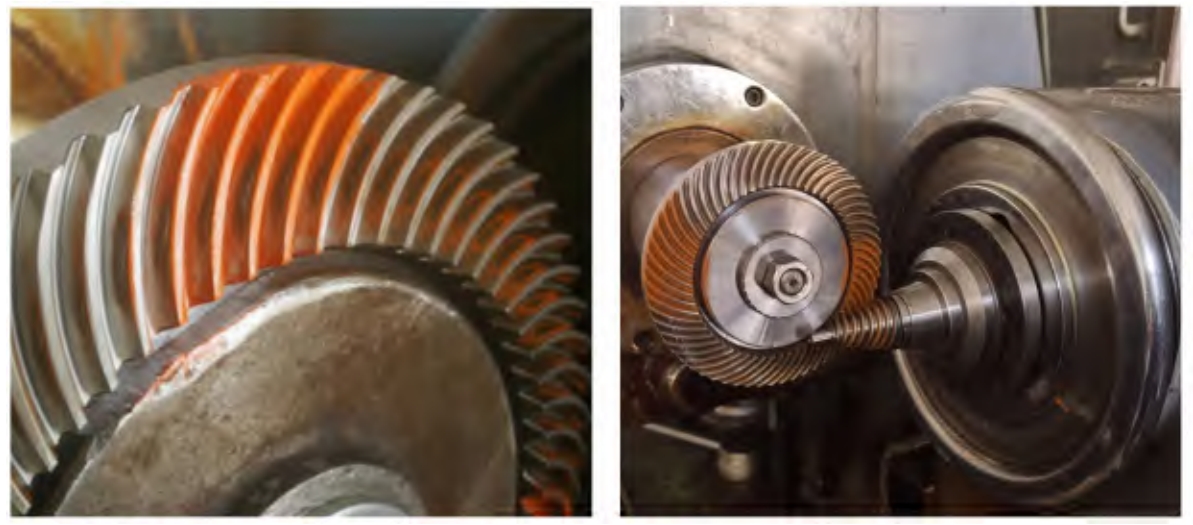

Gear forming grinding is a precision machining method that removes material through abrasive cutting. The key aspects of this process include the geometric design of the gear, the control of grinding force and heat, error analysis and compensation, the material characteristics and grinding performance, and gear inspection and quality control. The geometric design of the gear, which involves parameters such as tooth profile, number of teeth, module, and pressure angle, determines the basic shape and working characteristics of the gear, ensuring proper meshing and transmission efficiency. During the grinding process, a specialized forming grinding wheel is used, and its shape and motion trajectory are precisely controlled to guarantee the accuracy of the tooth profile and the surface quality. Error analysis and compensation are crucial for improving machining accuracy. By using numerical control technology to monitor and adjust the grinding parameters in real-time, errors resulting from machine accuracy, grinding wheel wear, and thermal deformation can be compensated. Different gear materials exhibit different grinding characteristics, and selecting the appropriate grinding wheel material and grinding parameters is essential for ensuring machining quality. After machining, strict inspection and quality control are required. Through gear profile measurement, surface roughness inspection, and gear meshing performance testing, the machining quality of the gear is evaluated to ensure that it meets the design requirements. In this chapter, based on the constructed tooth profile model of the double-point contact internal meshing curve configuration gear, the spatial contact traces between the forming grinding gears and the grinding wheels for the convex gear and the internal gear are calculated. Based on the spatial coordinate transformation between the gear and the grinding wheel, the corresponding grinding wheel profiles for the convex gear and the internal gear are designed, and the error analysis of the simulated grinding wheel profiles is performed.

2.2 Tooth Surface Equation of Double-Point Contact Internal Meshing Curve Configuration Gear

2.2.1 Establishment of Gear Pair Space Coordinate System

The internal meshing curve configuration gear pair consists of a convex gear and an internal gear. The fixed coordinate systems and are established. The coordinate systems and are fixed to the convex gear and the internal gear, respectively. It is assumed that the convex gear rotates around the axis with an angular velocity of , and the internal gear rotates around the axis with an angular velocity of . The center distance between the two axes is . After a time interval of , the convex gear rotates through an angle of , and the internal gear rotates through an angle of . Figure 2.1 shows the spatial coordinate relationship between the convex gear and the internal gear. and are vectors in the coordinate systems and , respectively. is the distance between the fixed coordinate points and , and and are the two contact points when the gear pair is in mesh.

Based on the coordinate transformation theory, the transformation relationship between the gear pair coordinate systems satisfies:

2.2.2 Gear Pair Tooth Surface Equation

The basic tooth profile of the convex gear consists of a tooth root transition arc and a contact region arc . When the gear pair is in mesh, it is in point contact form, and the normal tooth profile is shown in Figure 2.2.

is the radius of the transition arc , and is the radius of the contact region arc . is a design parameter that determines the position of points on the arc. is the offset of the center of the convex gear tooth profile, is the average pressure angle, is the minimum value of the design parameter , and is the maximum value. and are the addendum and dedendum heights, respectively, and is the total tooth height.