In this method, the gear parameters, i.e. modulus m, number of teeth Z and pressure angle α , It can be adjusted as needed. For standard gears, the modulus is derived from the following relationship:

Where: H is the depth of gear groove.

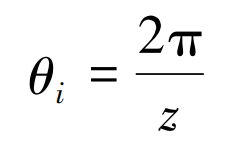

Therefore, gears with arbitrary modulus can be produced by adjusting the gear groove depth H. The number of teeth Z can be determined by changing the indexing angle, that is:

Where: θ I is the graduation angle.

Pressure angle α The half cone angle is the same as that of conical end milling cutter. When the half cone angle of the tool does not match the pressure angle, it can be realized by tilting the tool path surface. The pressure angle adjustment method is shown in the figure.

As shown in the figure, the tool path direction is inclined Δα , This is the difference between the pressure angle and the half cone angle. Therefore, any pressure angle can be achieved by modifying the tool path direction.