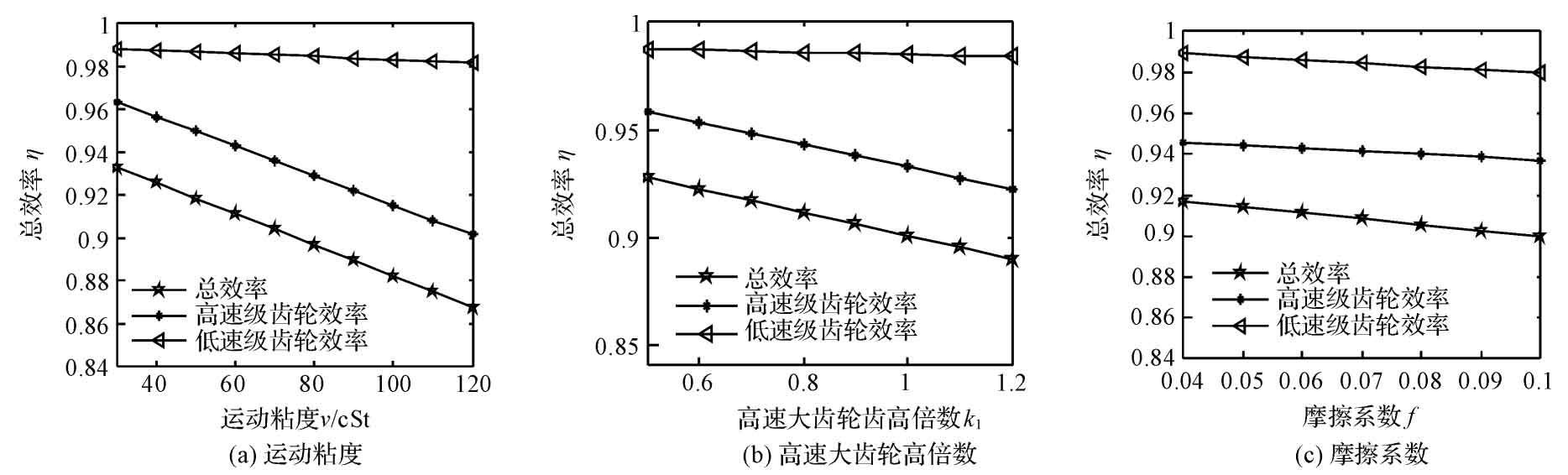

The efficiency change curve of the sample gearbox under different working environment parameters is drawn by using Matlab software. The relationship between kinematic viscosity, high multiple of high-speed gear teeth, friction coefficient and total efficiency is shown in Figure 1.

As shown in Figures 1 (a) and 1 (b), within the given variation range, the total efficiency of the gearbox of the wheel drive system decreases with the increase of the kinematic viscosity of the lubricating oil and the multiple of the tooth height of the high speed gear immersed in the lubricating oil. As shown in Figure 1 (c), within the given variation range, the total efficiency of the gearbox decreases with the increase of the sliding friction coefficient between the tooth surfaces.

To sum up, the efficiency of high-speed gear is the main factor affecting the total efficiency. Compared with high-speed gear, the efficiency of low-speed gear changes more obviously with the increase of friction coefficient, and the meshing loss of low-speed gear accounts for a large proportion of its total loss. The effect of kinematic viscosity on the total efficiency of the gearbox is more obvious. Compared with the low-speed gear, the high-speed gear has lower efficiency and more power loss under the same conditions.

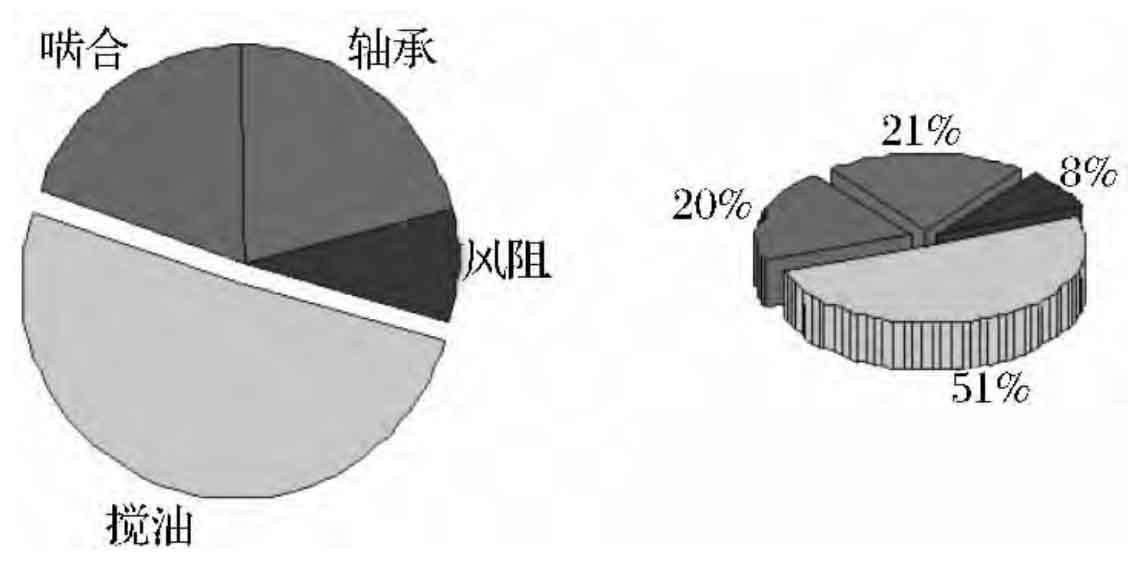

When the working environment parameters are fixed, the total efficiency of the gear box of the wheel drive system of the electric vehicle is calculated to be 0.911 4. The proportion of the four losses to the total power loss is shown in Figure 2. Among the total power loss, the oil mixing loss accounts for the largest proportion, accounting for 51% of the total power loss. The meshing loss and bearing loss account for approximately 20% and 21% of the total power loss, respectively. The wind resistance loss accounts for the smallest proportion, only 8%.