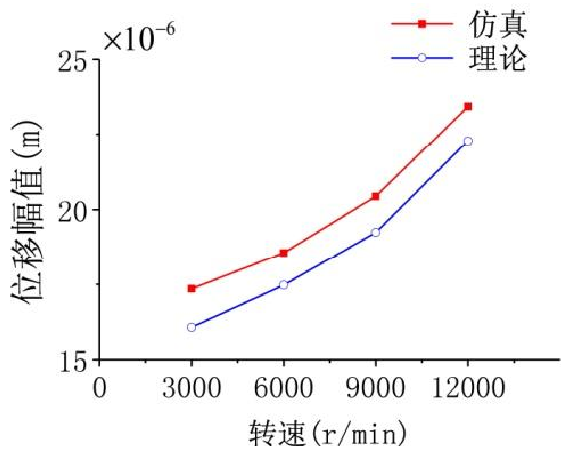

The lumped parameter method and ADAMS software are used to model and solve the dynamics of the same research system. In the first mock exam, the 2 methods are all studied and analyzed on the same model. Now, the amplitude and vibration characteristics of the rotor vibration are compared with the 2 methods when the rotor speed n is 3000, 6000, 9000, 12000r/min, the input power is 11kw, and the sealing material is C/C composite. Matlab is dimensionless. Firstly, it is dimensionless. Secondly, the vibration displacement of rotor solved by ADAMS simulation and lumped parameter method has obvious periodic amplitude fluctuation. Therefore, the average value of rotor vibration displacement amplitude in a period is solved firstly, and then the amplitude and frequency are compared. Finally, the simulation results of Adams are compared with MATLAB The percentage error of the calculated results.

From the figure It can be found that with the increase of the rotor speed, the radial vibration displacement of the rotor also increases, and with the increase of the speed, the increase of the rotor vibration displacement increases; because the simulation model established in this paper adds the corresponding material properties, constraints and driving constraints according to the theoretical model, the two curves are overall similar, and in the same order of magnitude; the two curves are similar, and in the same order of magnitude The difference is due to the difference between Adams and theory in the processing of the model or in the calculation method, but on the whole, the relative error is small, and the calculation results of theory and simulation show good consistency in the change law and trend.

According to the numerical results in the table, it can be seen that the main factors affecting the system vibration are 1-fold and 2-fold, while the 3-fold (high-frequency) is not obvious in theoretical calculation and simulation. By comparing the first three times of frequency, it can be found that although the theoretical and simulation methods are different and have a certain impact on the calculation results, the theoretical and simulation results are basically consistent, and the error percentage is small. To sum up, the rationality of the theoretical model is verified by comparing the simulation results with the theoretical results.