Transmission error is an important factor affecting the accuracy and dynamic characteristics of gear transmission. Efficient and accurate modeling and analysis of transmission error is an important foundation for improving the performance of gear transmission. Scholars at home and abroad have done a lot of research on modeling methods for gear transmission error. Common modeling methods include analytical methods, finite element methods, and semi-analytical methods. In order to improve the efficiency of solving problems, analytical methods are used to establish a calculation model for gear transmission error, which greatly shortens the solving time, but insufficient consideration of the structural elasticity of the gear results in limited accuracy of the solution. In order to shorten the solving time while ensuring accuracy

At present, many scholars have begun to study the application of semi-analytical methods in the analysis of gear transmission accuracy.Cylindrical Gear In addition, in terms of the analysis of factors affecting transmission error, based on finite element modeling, the influence of different quality materials on the static transmission error curve of gears has been explored. Based on analytical modeling, the influence of gear eccentricity on transmission error has been studied considering different degrees of eccentricity.

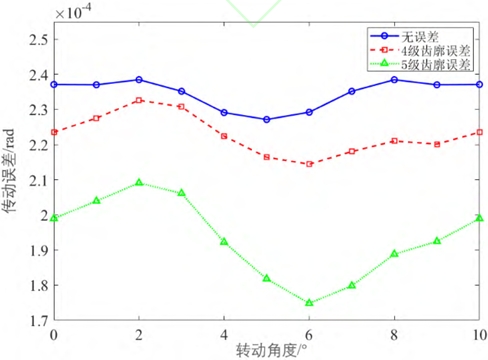

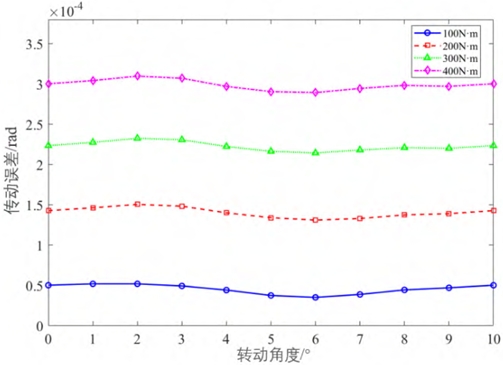

Research on gear transmission errors has not considered elastic errors. Therefore, this article takes involute cylindrical gears as the research object, establishes a gear contact model considering elastic errors based on a semi-analytical method, and combines deformation compatibility conditions and force balance equations to study the impact of elastic errors on transmission accuracy,Cylindrical Gear aiming to provide guidance for the engineering application of cylindrical gears.

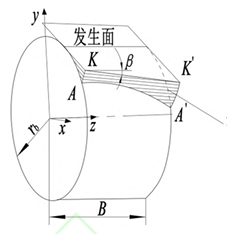

Based on the generation principle of involute cylindrical gear tooth surfaces, the tooth profile error is combined with the tooth surface equation to establish an error tooth surface model, Cylindrical Gear providing a geometric theoretical basis for the finite element solution of gear transmission errors.

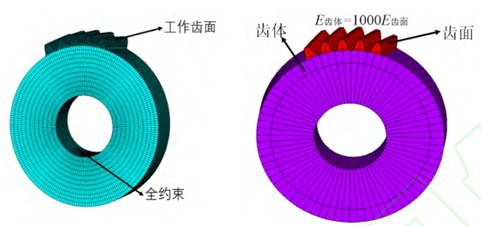

Due to the same parameters of the driving and driven gears, it is only necessary to establish a complete and partial finite element model of the driving wheel in ANSYS software to obtain the bending-shear deformation coefficients of the driving and driven gears .Cylindrical Gear Taking the helical gear as an example, its overall finite element model uses a five-tooth model. A full constraint is applied to the center hole of the gear to obtain a complete compliance matrix; the elastic modulus of the wheel body and the tooth body are the same. The local finite element model of the helical gear, where a full constraint is applied to the non-contact tooth surface, and the elastic modulus of the tooth body is 1000 times that of the tooth surface elastic modulus to ensure that only local contact deformation is included on the contact tooth surface. Cylindrical Gear The node coordinates and elements on the contact tooth surfaces of the driving and driven wheels are completely consistent.

The analysis steps for the transmission accuracy of cylindrical gears considering elastic errors are as follows:

First, based on the basic parameters of the gear, a geometric model of the gear is established to calculate the position of the gear contact line, and the gear contact line is discretized to obtain evenly distributed discrete points and determine their position coordinates.

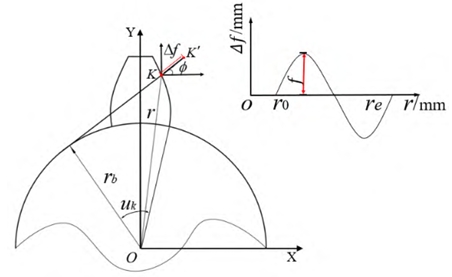

2) Based on the coordinates of the discrete contact points obtained, taking into account the tooth profile error, the magnitude of the tooth profile error corresponding to each contact point is determined by the distance from the contact point to the gear center. The resulting magnitude of the tooth profile error is substituted into the contact gap, and combined with the coordinates of the initial discrete contact points to obtain new contact point coordinates, and derive the overall deformation equation of the gear.

3) Assuming that the initial load has the same effect on all potential contact points, the displacement, overall flexibility matrix, and local contact flexibility matrix at each contact point can be obtained,Cylindrical Gear and then the complete flexibility matrix of the gear can be integrated.

4) Determine whether the contact point is engaged based on the contact force at the contact point: Fi < 0 N indicates that the point on the contact line is not engaged, and Fi > 0 N indicates that the point on the contact line is engaged. Obtain all the points of contact through iteration and update the compliance matrix.

5) Determine whether the result converges by checking if Fi+1-Fi <ε. If the convergence condition is not met, perform a second iteration until the final equation solution is obtained.

6) Calculate the transmission error of the gear at this time based on the obtained equation solution, and calculate the transmission error at the next time based on the above steps until obtaining a transmission error within one meshing cycle T,Cylindrical Gear and then end the calculation and output the transmission error.

Conclusion

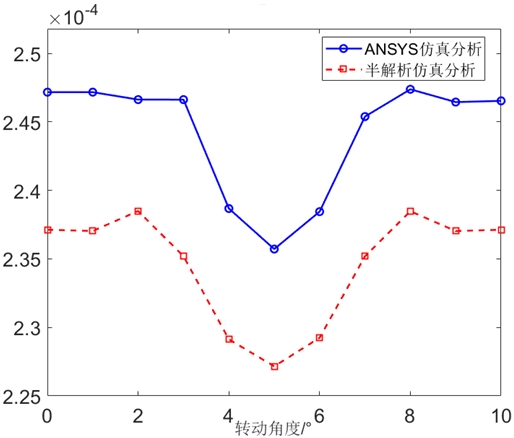

Combining the advantages of finite element simulation and analytical methods, Cylindrical Gear taking involute cylindrical gears as an example, a semi-analytical contact model of cylindrical gears considering elastic errors was established. The correctness of the constructed semi-analytical model was verified by comparing the results with those based on traditional finite element simulation methods. The results showed that the semi-analytical method can effectively improve the efficiency of solving the transmission accuracy of cylindrical gears. Compared with traditional finite element simulation methods, Cylindrical Gear the solving speed of this method was increased by 79.57 times, and the accuracy of the solution was high. At the same time, based on the constructed semi-analytical model, the influence of different loads and tooth profile error levels on the transmission accuracy of cylindrical gears was analyzed, providing guidance for the engineering application of cylindrical gears.