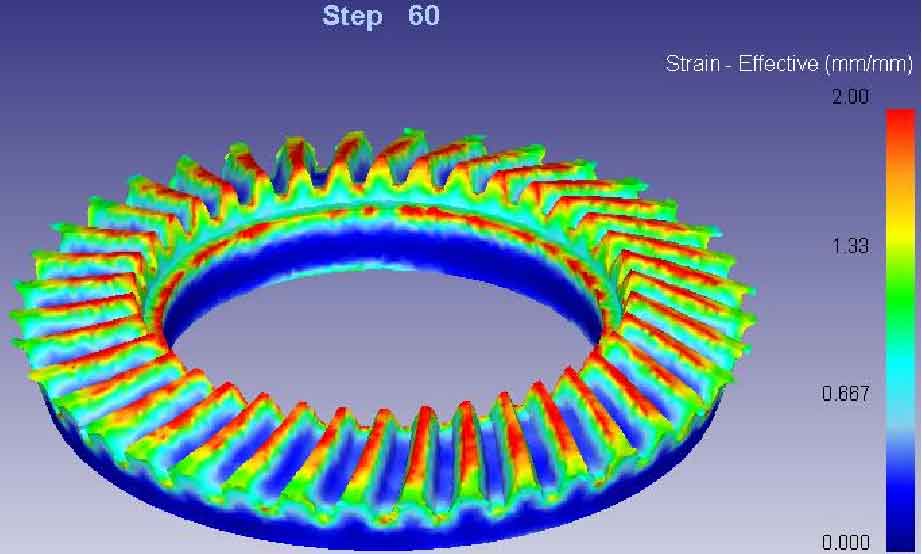

The figure shows the distribution of equal effect variation in the final step. From the figure, it can be seen that the places where the equal effect of spiral bevel gear becomes larger in the cold finishing process are mainly distributed in the tooth top of spiral bevel gear, and the equal effect of other parts becomes smaller.

In the whole cold finishing process of spiral bevel gear, the equivalent strain of tooth top increases with the increase of stroke, and the maximum equivalent strain is only 3 mm / mm, which is far less than the equivalent strain in the warm precision forging process of spiral bevel gear.

Therefore, the equal effect of spiral bevel gear cold finishing process becomes smaller, and the shape variable is relatively smaller.