The experimental scheme of dual frequency induction heating of bevel gear is as follows: install the medium and high frequency induction coils on the medium and high frequency power supply respectively, fix the bevel gear specimen on the lifting platform, adjust the spacing between the bevel gear specimen and the induction coil by controlling the lifting platform by personal computer, and collect and record the temperature data of bevel gear tooth surface through temperature measuring instrument.

First conduct medium frequency induction heating, preheat the bevel gear, and heat the temperature of the tooth top to about 900 º C. then move the bevel gear specimen to the high-frequency induction coil through the lifting platform, and adjust the spacing between the bevel gear specimen and the high-frequency induction coil for high-frequency induction heating. Finally, the bevel gear is quenched and cooled.

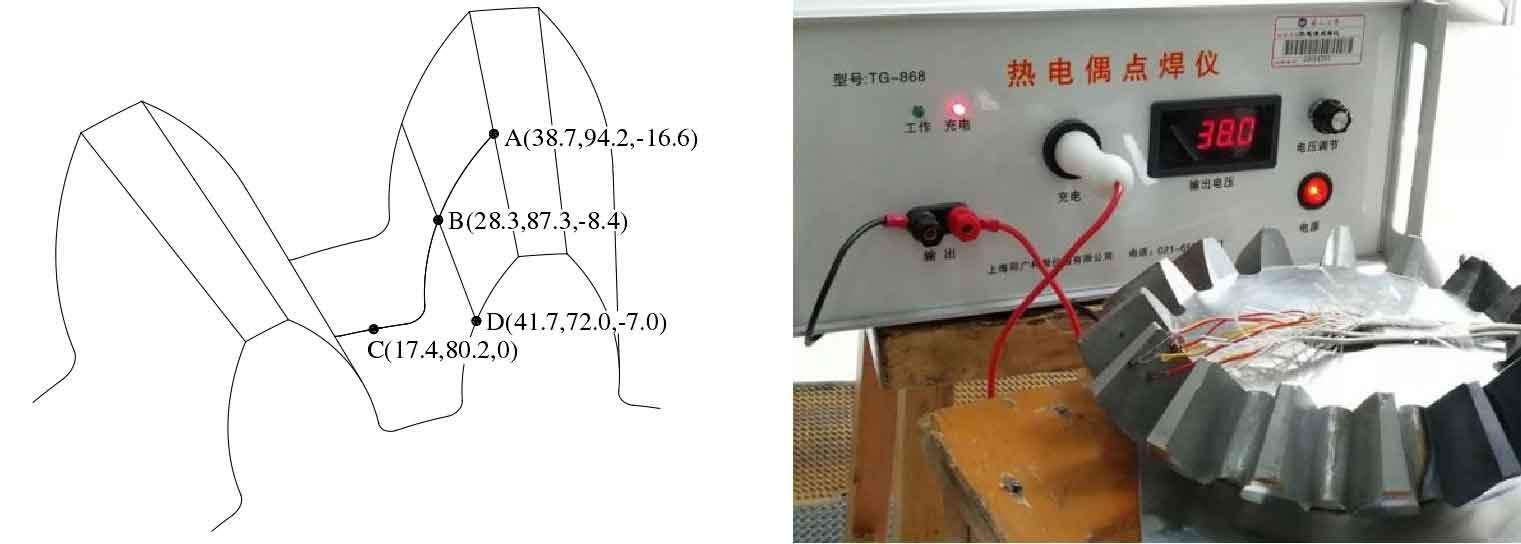

When the bevel gear is heated by dual frequency induction, the thermocouple temperature measuring line is used to measure the surface temperature of the bevel gear. The thermocouple spot welding instrument of the laboratory is used to weld the thermocouple on the surface contour of the bevel gear, with a total of 4 points. The specific conditions are as follows: point a is located at the tooth top, points B and D are located on the tooth surface, and point C is located at the tooth root, as shown in the figure.

Before the experiment, check whether the medium and high frequency power supply, power supply water cooling system and induction coil water cooling system work normally. Before the formal dual frequency induction heating experiment, the normal operation of the temperature detection device should also be ensured. Therefore, before the formal induction heating, connect the medium frequency power supply for a short time to check whether the temperature measuring instrument can detect and record the 4-point temperature data normally. If the temperature data cannot be detected, the problem may be the wiring of the temperature measuring instrument or the temperature measuring software. If the data of only one point fails to be recorded normally, it may be that the thermocouple joint of this group fails to be spot welded normally, and it should be spot welded again. If there is no problem, carry out the double frequency induction heating experiment of bevel gear normally.