When the cyclic contact stress on the tooth surface exceeds the fatigue limit of the material, a micro crack appears on the tooth surface or a certain depth of the tooth surface. The crack develops gradually, and the micro metal sheet falls off from the tooth surface to form a pit. This phenomenon is called fatigue pitting. The position of Nm is mostly located at the lower side near the node line, as shown in Figure 1.

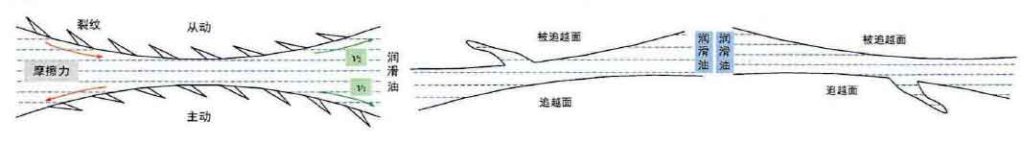

In the meshing process of involute spur gear pair, under the action of cyclic contact stress, cracks always appear along the direction of friction due to the sliding of tooth surface, as shown in Fig. 2. It can be seen from the figure that the direction of friction force and the direction of crack change alternately with the pitch line as the boundary. The point contact model at any meshing position on the tooth surface can be equivalent to the contact of two cylindrical rollers. As shown in Figure 3, the contact velocity of two rollers (active and driven) is V1 and V2, where V1 > V2. The active rollers are defined as the overrunning surface and the driven rollers are defined as the overrunning surface, and the lubricant is filled between the rollers and cracks enter.

(b) Surface crack of overtaken roller

(c) Surface crack of overtaking roller

According to the movement direction, shown in figure 3 (a) direction shown in the figure friction and cracks, and the surface is from right to left to engage in turn, to be overtaking surface crack son contact model (FIG. 3 (b)), the contact point moves, crack mouth contact first, will crack mouth sealed, makes the crack in lube oil pressure high, and the crack tip at the bottom of the existence of stress concentration, so as to make the crack to expand; For the overpass crack sub-contact model (Fig. 3 (c)), when the contact point moves, the crack abdomen contacts first to squeeze out the oil inside the crack and reduce the oil pressure, thus slowing down the crack propagation. Combined with the meshing contact characteristics of the tooth surface, the direction from the pitch line to the tooth root is the traversal surface, and the direction from the pitch line to the tooth tip is the traversal surface. Therefore, cracks below the pitch line are easy to expand and pitting corrosion occurs, which is consistent with the pitting failure characteristic figure in Fig. 1.