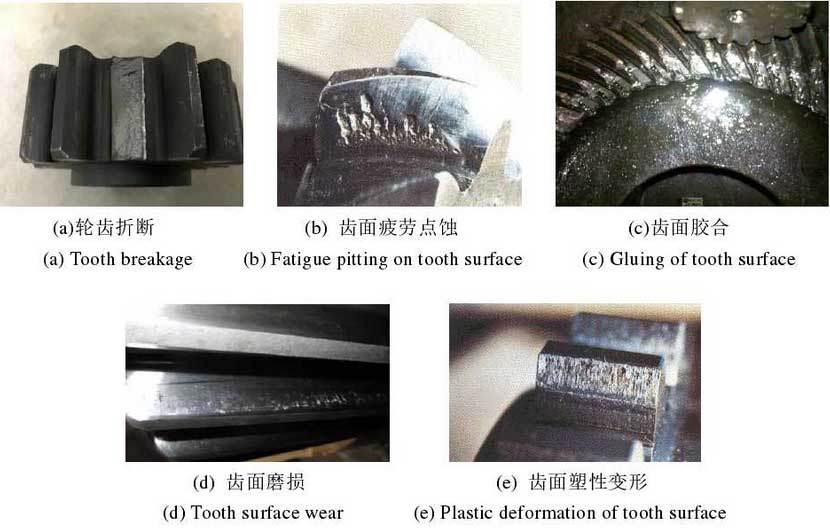

In most cases, the failure of gear teeth is the result of damage accumulation. Due to the different manufacturing processes of gears and the different load forms in different working situations, there are many kinds of damage and failure forms of gears. It mainly includes: gear fracture, tooth surface fatigue pitting, tooth surface gluing, tooth surface wear, tooth surface plastic deformation, etc. However, with the continuous improvement of gear surface treatment technology, the contact fatigue strength of the gear has been greatly improved, so the fracture of gear teeth under the action of bending fatigue stress has become a major failure mode.

Under the cyclic action of compound load, the bending stress is produced at the root of the gear, which leads to the initiation of micro cracks. The cracks extend to the macro cracks under the further action of the bending stress. Finally, the proportion of the gear bending fatigue fracture failure is 32.8% of the total gear failure. The reason for this phenomenon is that the maximum bending stress of the gear is produced at the root of the gear in the actual working process, and the stress concentration phenomenon is easy to occur at the tooth root position.

The proportion of bending fatigue tooth fracture failure, contact fatigue failure, overload tooth fracture failure and surface wear failure of gear is more than 10%, and the proportion of these four failure forms together accounts for about 90% of the total failure mode, which is the main failure mode of gear. This is mainly due to the different working environment of gears in different working situations and the different action forms of working load.

As shown in Fig. 1, there are five common failure forms of gears.