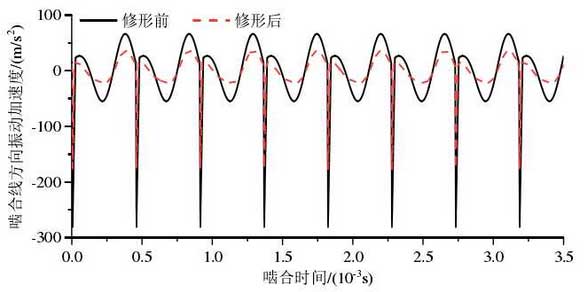

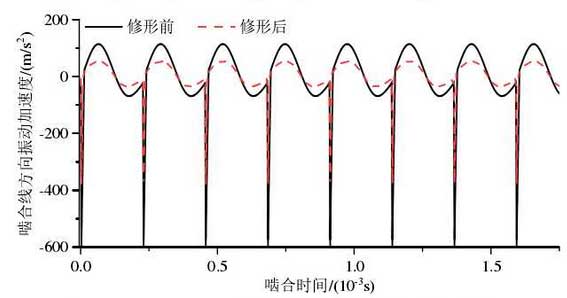

In order to test the vibration reduction effect of single-stage high-speed helical gear transmission after modification, the time-varying meshing stiffness curve after tooth surface modification can be obtained by using the load-bearing error curve after tooth surface modification. The time-varying meshing stiffness curve and meshing impact curve before and after tooth pair modification are input into the dynamic equations of single-stage high-speed helical gear transmission as shown in the formula, and the single-stage helical gear is obtained after solving The relative vibration acceleration time domain diagram of meshing line direction before and after wheel drive repair is compared and analyzed. Figure 1 shows the time domain diagram of system vibration at 6000rpm and Figure 2 shows the time domain diagram of system vibration at 12000rpm.

In Fig. 1, after tooth surface modification, the sudden change value of acceleration caused by meshing impact decreases from 266.68 M / S2 to 176.41 M / S2, and the root mean square value of relative vibration acceleration decreases from 52.38 M / S2 to 27.92 M / S2.

In Fig. 2, the sudden change value of acceleration caused by meshing impact decreases from 574.11m/s2 to 376.91m/s2, and the root mean square value of relative vibration acceleration decreases from 103.91m/s2 to 55.77m/s2. This shows that the tooth surface modification has better vibration reduction effect on single-stage helical gear transmission.