At present, the research on the law of fatigue crack growth mainly uses experimental methods and numerical analysis methods. According to the theory of damage mechanics, fatigue crack formation starts from loading until the crack grows to a certain crack size α 0。( The number of cycles or time experienced during the process up to the detectable size is the life of fatigue crack formation. The fatigue crack growth rate is obtained based on experiments and experience, but there is no clear definition. Manson takes the crack length of 0.076mm (1 / 32 inch) as the critical size of crack initiation, and J. schijve defines the crack length of 0.5mm as the crack initiation size, B. Baidurya gives the expression of crack initiation size:

Where, Δ Kth is the threshold value of stress intensity factor; σε Is the endurance limit of the material; Δ Kth and σε All are measured when the stress ratio R = – 1.

In order to characterize the strength of the stress-strain field at the crack tip, the concept of stress intensity factor fire is used in fracture mechanics. Different crack forms have different stress intensity factors, which control the whole deformation field near the crack tip, which is directly proportional to the stress, strain and displacement of the crack tip. Stress intensity factor is a function of load size, loading mode and crack size, crack shape, component geometry and geometric size. The general expression of the stress field near the crack tip is as follows:

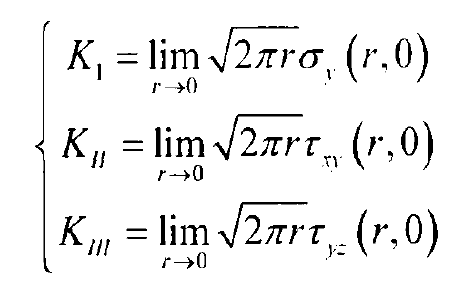

The stress intensity factor can be defined by the crack tip stress field: