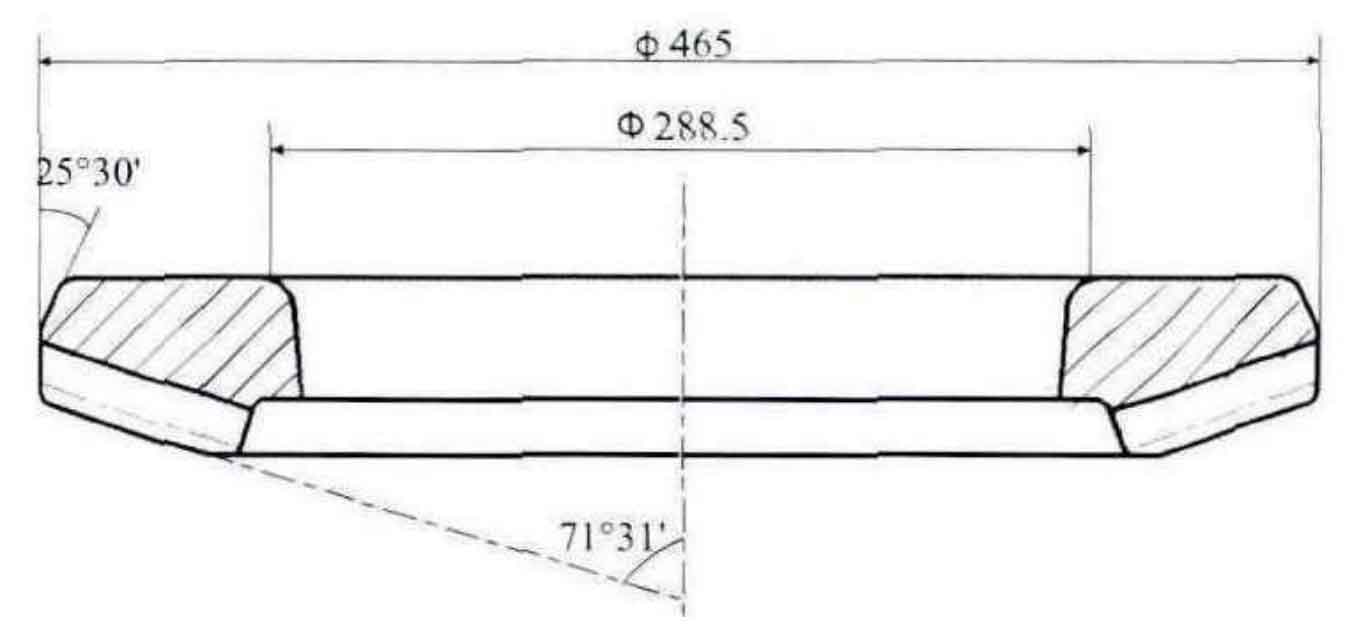

According to the process scheme of “blanking upsetting punching compound rolling preform final forging”, the rings rolled to the required preform size are finally forged on a large tonnage screw press or hot die forging press. Because the upsetting and punching compound forming process is easy to control, this paper mainly studies the rolling preform and final forging process. The figure shows the forging of spiral bevel gear. The maximum outer diameter of the studied constant height spiral bevel gear is 465mm. The face cone angle of spiral bevel gear is 71 ° 31 ‘and the back cone angle is 25 ° 30’.

The initial blank is determined as Φ For 150x328mm round bar, according to the principle of constant volume, the forging blank volume is consistent with the blanking volume. The forging blank size is designed according to the die structure size and formed by rolling process. The calculated blank volume is 5796238mm3, and the preformed blank size is: inner diameter of ring Φ 320mm, outer diameter of ring Φ 430mm, axial height of ring 83mm.