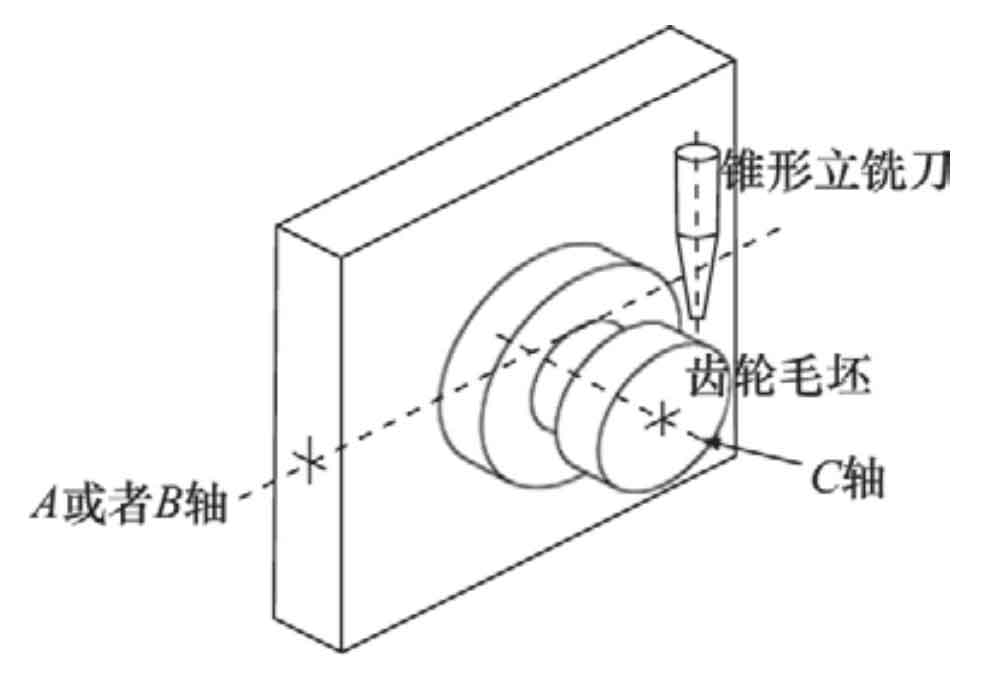

The proposed gear cutting method can be directly realized by using a 5-axis machining center. When the vertical machining center is used, the a-axis or b-axis is inclined by 90 °, and the c-axis realizes the rotation of gear blank and has the indexing function. The setting of 5-axis machining center is shown in Figure 1.

The tool moves zigzag on the horizontal plane in contact with the pitch cylinder. When machining spur gear, according to the formula, the gear blank rotates synchronously with the motion of the tool. When machining helical gears, the gear blank rotates according to the formula, and the required NC code is very simple. The model of 5-axis machining center used in the test is Japan Mazak variaxis 500-5x. The gear cutting on the 5-axis machining center is shown in Figure 2.

The gears processed by the 5-axis machining center are shown in Figure 3.

After measurement, the common normal length deviation of spur gear is shown in Figure 4.

As can be seen from Figure 4, although the processing conditions are not optimized, most of the deviations are within 10 μ Within M. The results show that this method has high accuracy in gear machining.