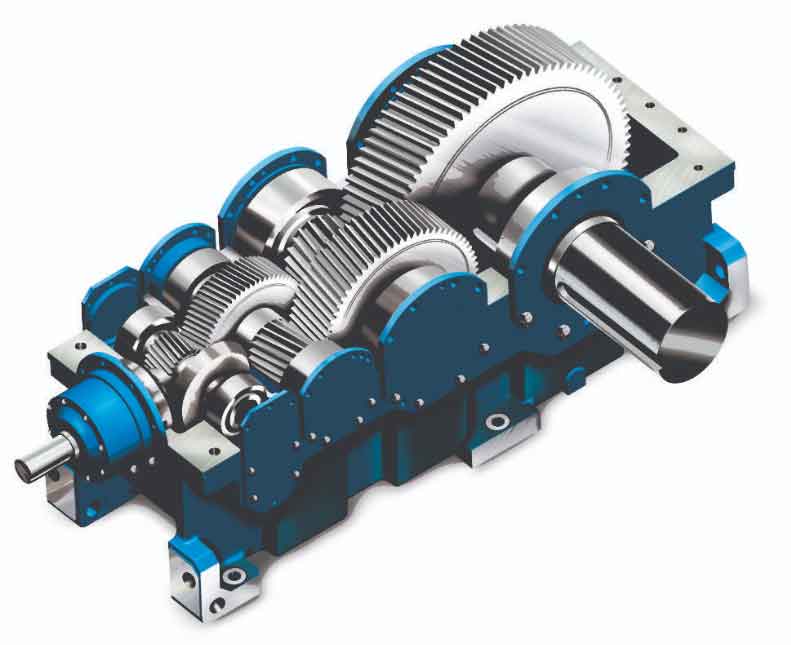

As gearbox play an important role in the mechanical drive system of wind turbine,Its main function is that the generated mechanical Power transfer to the generator and the corresponding speed under the action of wind turbines in the wind, thus ensuring the normal operation of wind turbine gearbox is extremely important.And the type of large-scale wind turbine gear box is the subject in this paper.Based on signal analysis.Expert system about state monitoring and fault diagnosis of the wind turbine gear box is developed successfully.

Gearboxes play a crucial role in the mechanical drive system of wind turbines. Wind turbines are designed to convert the kinetic energy of the wind into electrical energy, and the gearbox serves as an essential component in this process. Here’s how gearboxes are important in wind turbine drive systems:

1. Speed Conversion: Wind turbines operate most efficiently at certain rotational speeds. However, wind speeds are variable, and they may not always match the ideal operating speed. Gearboxes help convert the low-speed rotational motion of the wind turbine rotor into the higher speed required by the generator to produce electricity.

2. Torque Amplification: Wind turbines need to produce significant torque to turn the generator and produce electrical power. Gearboxes can amplify the torque from the low-speed rotor to the high-speed generator, allowing the turbine to generate sufficient electrical power even with relatively low wind speeds.

3. Efficiency Improvement: Gearboxes allow wind turbines to achieve higher efficiency by optimizing the rotational speed and torque levels. By adjusting the gear ratio, the gearbox ensures that the turbine operates at its most efficient point for a given wind speed.

4. Size Reduction: Gearboxes can help reduce the size and weight of the generator, as the higher rotational speed from the gearbox allows for a smaller and more lightweight generator.

5. System Protection: Gearboxes also serve as a protective element in the wind turbine drive system. They can absorb and dampen sudden changes in wind speeds or mechanical stresses, thus preventing damage to the turbine components.

6. Load Balancing: In multi-megawatt wind turbines, where the loads on the rotor and generator can be significant, gearboxes help balance the loads and distribute them evenly across the drive train components, including the main shaft and bearings.

7. Control and Regulation: Gearboxes provide flexibility in controlling and regulating the rotational speed of the generator, which is important for grid stability and power output optimization.

However, it’s worth noting that gearboxes in wind turbines can be subject to significant mechanical stresses and wear due to the variable wind conditions and the large loads they must handle. Therefore, gearbox design, lubrication, maintenance, and reliability are critical considerations in wind turbine engineering to ensure the long-term performance and reliability of the entire wind energy system. In recent years, some wind turbine designs have started using direct-drive systems that eliminate the need for a gearbox, relying on a low-speed generator directly connected to the rotor to produce electricity, which can simplify maintenance and improve overall system efficiency.

The data acquisition system is composed of vibration acceleration transducers ,charge amplifier and NlUSB9215A-DAQ Card and other instruments.And the knowledge base of expert system is established by the characters of signal when faults happen in the wind turbine gearbox.Based on a large number of experimental data,the character of state monitoring is gained from second analysis of kurtosis value and the character of fault diagnosis is consist of energy proportion spectrum of the data.By using BP neural network,the gray relational theory and D-S evidence theory, the inference engine of expert system is designed successfully .The validity and correctness of these principles applied to fault diagnosis are established by simulation· In this paper,the structure of the expert system is devised by the tools of UML, computer Assistant Software Engineering,MATLAB7.0and VisualBasic6.0.Finally,the experiment shows validity and correctness of the expert system applied to the fault diagnosis of large-scale wind turbines gearbox.