Abstract

External Helical Gear Pump Mixers (EHGPM) are widely utilized in various industries due to their high efficiency, compact design, and ease of maintenance. This study focuses on numerically simulating the gelatin/water two-phase flow field within the mixer and optimizing its structural design to enhance mixing uniformity. The Volume of Fluid (VOF) model is employed to analyze the effects of operational conditions and mixer components on the mixing process. Several optimization strategies are proposed and evaluated to improve the mixing efficiency. The results provide valuable insights into the design and operation of EHGPMs for industrial applications.

Introduction

External Helical Gear Pumps (EHGPs) are essential components in many industrial processes, particularly in the food, pharmaceutical, and chemical industries. EHGP mixers facilitate the mixing of two or more fluids, enhancing their homogeneity for downstream processes. The helical gear in these pumps create a continuous and stable flow, reducing pulsations and noise compared to spur gear pumps. However, the complex internal flow dynamics and narrow gear mesh gaps pose significant challenges for accurate simulation and optimization.

This study aims to numerically simulate the gelatin/water two-phase flow field within an EHGPM and optimize its structural components to enhance mixing uniformity. The specific objectives include:

- Modeling and Simulating the Two-Phase Flow Field: Develop a three-dimensional transient numerical model of the EHGPM using the VOF multiphase flow model.

- Analyzing Operational Conditions: Investigate the effects of varying inlet velocities and rotational speeds on the mixing process.

- Structural Optimization: Optimize the center splitter and inlet configurations to improve mixing efficiency.

- Validation and Discussion: Validate the simulation results through experiments and discuss the implications for industrial applications.

Modeling and Simulation Methodology

Geometric Model and Meshing

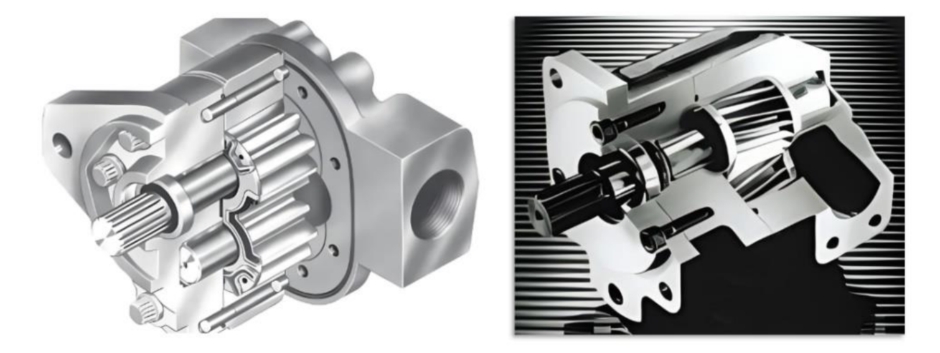

The EHGPM model used in this study comprises a pair of helical gear, a mixer housing, a center splitter, and inlet/outlet ports (Figure 1). The key geometric parameters are summarized in Table 1. The computational domain is discretized using structured grids generated in ANSYS Meshing, with refined meshes in the narrow gear mesh regions to capture the complex flow dynamics.

| Parameter | Value |

|---|---|

| Gear tooth number | 8 |

| Module (mm) | 6.35 |

| Pressure angle (°) | 20 |

| Helix angle (°) | 8 |

| Center distance (mm) | 51 |

| Gear width (mm) | 665.74 |

| Center splitter height (mm) | 50 |

| Center splitter length (mm) | 646 |

Table 1: Key geometric parameters of the EHGPM.

Governing Equations

The fluid flow within the EHGPM is governed by the continuity and Navier-Stokes equations, along with the VOF multiphase flow model. The standard k-ε turbulence model is employed to capture the turbulent flow characteristics. The governing equations are discretized using the finite volume method and solved using the commercial CFD software ANSYS Fluent.

Boundary Conditions

The inlet velocity and rotational speed are controlled through user-defined functions (UDFs) in Fluent. The outlet is modeled as a pressure outlet, and the mixer housing walls are set as no-slip boundaries. The initial conditions are set to represent a fully filled gelatin solution within the mixer.

Simulation Setup

Transient simulations are performed using a time step of 0.01 seconds, corresponding to a fraction of the gear rotation period. The pressure-implicit with splitting of operators (PISO) algorithm is used for pressure-velocity coupling, and second-order upwind schemes are adopted for spatial discretization.

Analysis of Operational Conditions

Effects of Inlet Velocity

Simulations are conducted at various inlet velocities (0.159, 0.318, 0.636, and 1.272 m/s) to investigate their impact on mixing uniformity. The results are analyzed in terms of water volume fraction distributions and gelatin viscosity variations.

Water Volume Fraction Distributions: At low inlet velocities, water primarily accumulates near the inlet, resulting in a rich water zone at the mixer outlet. As the inlet velocity increases, water distribution becomes more uniform, but excessive velocities lead to centralized water accumulation.

Gelatin Viscosity Variations: The gelatin viscosity decreases significantly in the rich water zone due to water dilution. At an optimal inlet velocity of 0.318 m/s, the viscosity variations are more gradual, promoting mixing uniformity .

Effects of Rotational Speed

The rotational speed is varied from 8 to 90 rpm to assess its impact on mixing efficiency. The results are presented in terms of water volume fraction distributions and gelatin velocity profiles.

Water Volume Fraction Distributions: Increasing the rotational speed promotes water transport to the mixer outlet, enhancing mixing uniformity. However, excessively high speeds can lead to premature water ejection.

Gelatin Velocity Profiles: The gelatin velocity increases with rotational speed, particularly in the rich water zone. However, excessive speeds can lead to flow instability and reduced mixing efficiency .

Structural Optimization

Center Splitter Design

The standard center splitter is replaced with staggered splitters at various inclination angles (8°, 12°, 16°, 20°, 30°, 45°, and 60°). The effects on water volume fraction distributions and gelatin viscosity are analyzed.

Water Volume Fraction Distributions: Splitters with moderate inclinations (e.g., 20°) promote uniform water distribution, while excessive inclinations (e.g., 60°) restrict water flow.

Gelatin Viscosity Variations: Moderate splitter inclinations minimize viscosity variations, enhancing mixing uniformity .

Inlet Configuration

Three inlet configurations are evaluated: a single inlet at the mixer front, dual inlets at the front and rear, and a single inlet with a front cover.

Water Volume Fraction Distributions: The dual inlet configuration enhances water distribution at the mixer rear, while the front cover effectively eliminates the rich water zone.

Gelatin Viscosity Variations: The dual inlet and front cover configurations minimize viscosity variations, promoting uniform mixing .

Validation and Discussion

The simulation results are validated through experimental measurements of gelatin viscosity at the mixer outlet. A good agreement is observed between the simulated and experimental data, with an error margin of < 2%.

Implications for Industrial Applications

The findings of this study have significant implications for the design and operation of EHGPMs in industrial settings:

- Optimal Inlet Velocity and Rotational Speed: Identifying the optimal inlet velocity and rotational speed is crucial for balancing mixing efficiency and flow stability.

- Optimized Center Splitter Design: Moderate splitter inclinations promote uniform water distribution and reduce viscosity variations.

- Enhanced Inlet Configurations: Dual inlets and front covers can significantly improve mixing uniformity, particularly in large-scale industrial mixers.

Conclusion

This study presents a comprehensive numerical simulation and structural optimization of the gelatin/water two-phase flow field in an EHGPM. The effects of operational conditions and mixer components on mixing efficiency are analyzed in detail. The optimized designs, including staggered center splitters and enhanced inlet configurations, demonstrate significant improvements in mixing uniformity. These findings provide valuable insights for the design and operation of EHGPMs in various industrial applications.