When a pair of helical gears are engaged, the contact line of the two gear surfaces is a straight line inclined to the axis. During the meshing process of the two tooth profiles, the contact line first enters the meshing from the front end face. With the rotation of the tooth, it gradually enters the meshing area along the tooth width. At this time, the length of the contact line of the tooth profile increases gradually from zero until the rear end face of the gear pair When the contact line reaches the meshing point, all tooth widths enter the meshing area, and the length of contact line reaches the maximum value. After a period of meshing, the front face begins to break away from the meshing area, and the contact line begins to decrease gradually. When the last end face of the tooth width disengages from the meshing area, all the teeth are out of engagement.

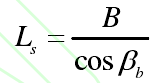

The maximum length of the contact line is as follows when the helical gear is fully engaged in the meshing area

The contact line of helical gear is gradually increased to SL as the gear rotates. When the helical gear is out of engagement, the contact line gradually decreases. As shown in Figure 2 and figure 3, a pair of helical gear pair contact line change diagrams are established respectively by using and considering the coincidence degree.

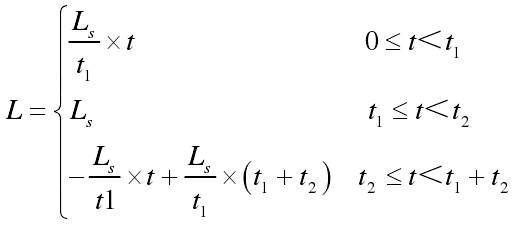

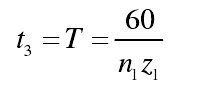

Let the driving wheel rotate at a constant speed, and its speed is N1. Thus, the time T1 when a pair of helical gears are fully engaged and the time T2 from the beginning of engagement to the beginning of disengaging can be solved. According to the calculation method of helical gear contact line proposed by Yang et al., T1 and T2 can be obtained respectively as follows, among which the expressions of θ 1 and θ 2 can be referred to:

According to the above figure 2, the relationship between the contact line L and a pair of helical gears can be solved

When each pair of gears of planetary gear system are meshed, the coincidence degree is greater than 1, so there are many pairs of gears meshing at the same time, as shown in Figure 4 below. The change of contact line of gear pair when multiple pairs of gears are engaged at the same time is drawn.

According to figure 4, the total contact line length l can always be solved when the helical gear is meshed with multiple teeth