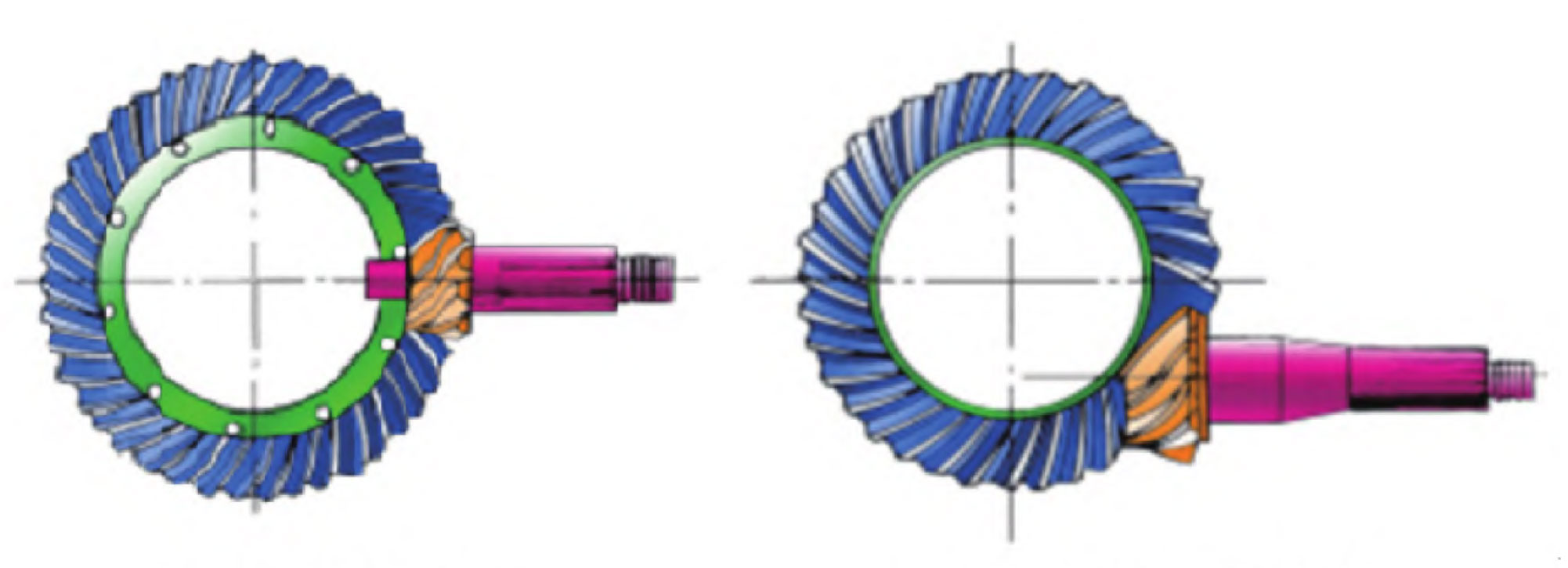

As a more complicated bevel gear in gear transmission, quasi hyperboloid gear has a series of advantages, such as strong bearing capacity, high transmission efficiency, smooth transmission, low noise and large reduction ratio. It is widely used as the main reducer gear of automobiles and becomes a key component in automobile drive axle. Compared with the spiral bevel gear, the large and small wheels of the quasi hyperboloid gear have an extra offset distance (as shown in the figure), which can effectively increase the smoothness and off-road performance of the vehicle when driving. In addition, the quasi hyperboloid gear has relative sliding along the tooth length direction and tooth height direction, which is easy to run in, and easy to grind after heat treatment, which is conducive to improving the tooth surface contact area, improving the tooth surface finish and reducing noise. Therefore, the research on quasi hyperboloid gear has more important practical significance and value.

In recent years, scholars at home and abroad have carried out relevant research on tooth cutting design, machining methods, installation errors and other aspects of quasi hyperboloid gears. Shih et al. proposed the mathematical model of the universal profile roll quasi hyperboloid bevel gear cutter, which is used to simulate the cutting motion of Klingelnberg, Gleason and Oricon tooth systems. Wang et al. proposed a calculation method to convert the mechanical settings of a universal shaking table gear cutting machine into a 6-axis gear cutting machine suitable for the Cartesian coordinate system. On the Free ⁃ Form bevel gear machine, the tooth length direction can be corrected without modifying the tool tip radius and tool tooth shape angle. Takeda et al. analyzed the meshing performance of quasi hyperboloid gears, and measured the transmission error through tests. Dong Xuezhu systematically introduced the meshing theory and gear milling principle of spiral bevel gears and quasi hyperboloid bevel gears, and combed the surface hobbing cutting blank design and gear milling adjustment methods of Oricon gear system and Klingelnberg gear system. Fang Zongde et al. carried out preliminary theoretical exploration on the optimal tooth cutting design of quasi hyperboloid gear generated by tool inclination fully through local synthesis method. Tang Jinyuan and others deduced the working tooth surface equation and the transition surface equation based on the rocker machine tool for the full development of quasi hyperboloid gears from the cutter inclination, which provided an accurate geometric modeling for the load bearing contact analysis of gear teeth.

Based on the coordinate system of the universal rocker type gear cutting machine, the mathematical model for hobbing quasi hyperboloid gears based on the tool inclination full generation method is derived on the new vertical 6-axis CNC gear cutting machine, which is used to guide the actual processing of quasi hyperboloid gears.