Taking the initial forging temperature of spiral bevel gear as 1000 ° C, 1050 ° C and 1100 ° C and the friction coefficient as 0.3 and 0.7 respectively, the forging process of driving spiral bevel gear blank is numerically simulated, and the influence of initial forging temperature and friction coefficient of spiral bevel gear on the forming effect is analyzed.

1.Equivalent stress-strain distribution under different conditions

When the friction coefficient is 0.3 and 0.7 respectively, the equivalent stress and strain distributions under different initial forging temperatures of spiral bevel gears are shown in Figures 1, 2, 3 and 4.

The numerical simulation results are shown in Table 1.

| Programme | 1 | 2 | 3 | 4 | 5 | 6 |

| Temperature (° C) | 1000 | 1000 | 1050 | 1050 | 1100 | 1100 |

| Coefficient of friction | 0.3 | 0.7 | 0.3 | 0.7 | 0.3 | 0.7 |

| Equivalent stress (MPa) | 568 | 836 | 561 | 819 | 558 | 802 |

| Equivalent strain | 5.71 | 6.93 | 5.62 | 6.51 | 5.58 | 6.39 |

It can be seen from the above chart that the forging process of the driving spiral bevel gear blank is the same as that of the driven spiral bevel gear. In the range of 1000 ° C-1100 ° C, when the friction coefficient is the same, the higher the initial forging temperature, the smaller the stress-strain value during the final forging; When the initial forging temperature is the same, the smaller the friction coefficient, the smaller the stress-strain value at the final forging. The influence of friction coefficient is greater than that of initial forging temperature.

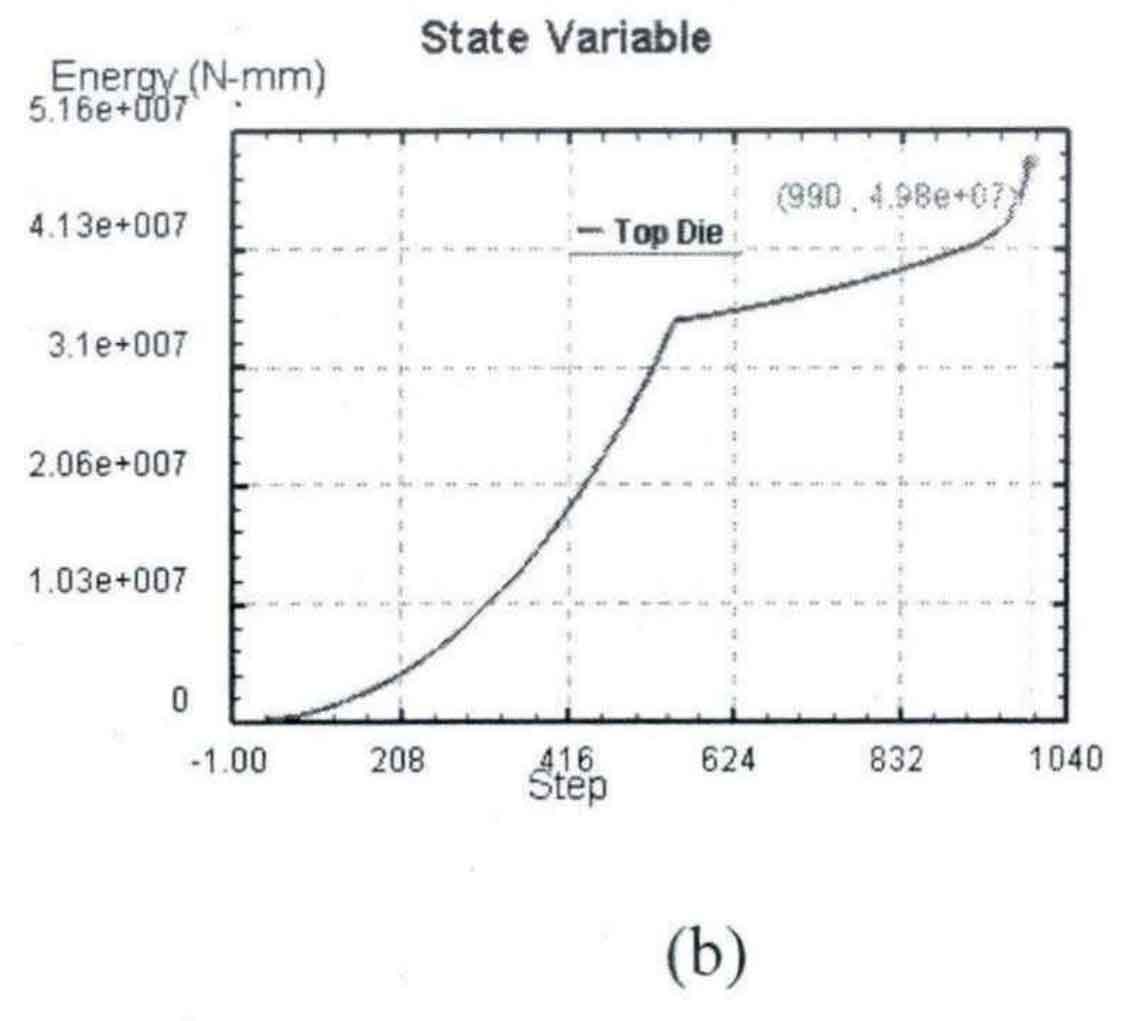

2.Energy consumption curve of iteration step under different conditions

When the friction coefficient is 0.3 and 0.7 respectively, the energy consumption curve of iterative steps under different initial forging temperatures is shown in Fig. 5 and Fig. 6.

The numerical simulation results are shown in Table 2.

| Programme | 1 | 2 | 3 | 4 | 5 | 6 |

| Temperature (° C) | 1000 | 1000 | 1050 | 1050 | 1100 | 1100 |

| Coefficient of friction | 0.3 | 0.7 | 0.3 | 0.7 | 0.3 | 0.7 |

| Forging energy consumption (kJ) | 54.3 | 58.8 | 49.8 | 54.4 | 49 | 53.8 |

It can be seen from the above chart that in the range of 1000 ° C-1100 ° C, when the friction coefficient is the same, the lower the initial forging temperature, the greater the forging energy consumption of spiral bevel gear. Moreover, the lower the temperature, the faster the increase of forging energy consumption is in the range of 1000 ° c-1050 ° C than that in the range of 1050 ° c-1100 ° C. When the initial forging temperature is the same, the greater the friction coefficient, the greater the forging energy consumption of spiral bevel gear.