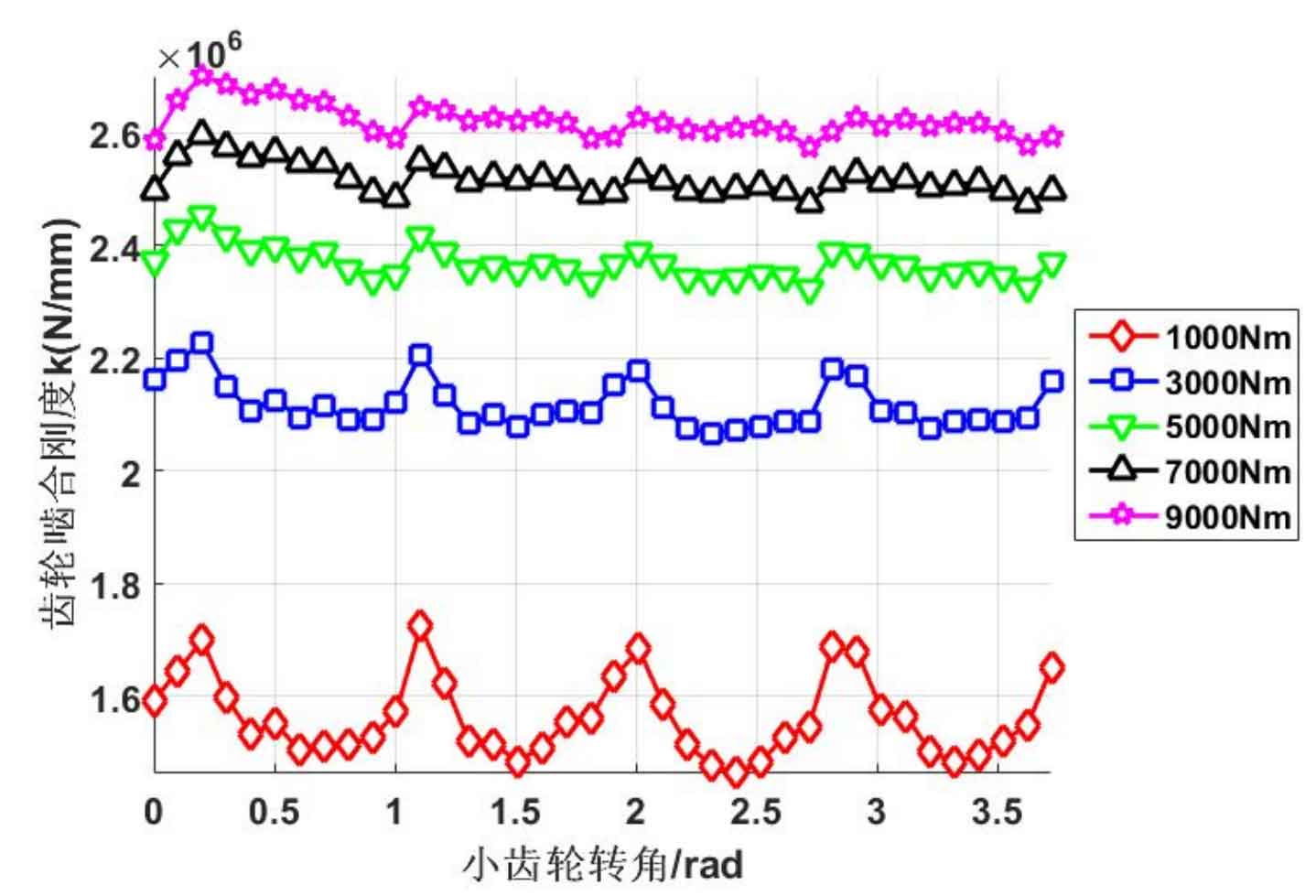

The following is a comparison of the change law of gear mesh stiffness when the gear load is different. Here, the resistance moments of 1000nm, 3000Nm, 5000NM and 7000nm respectively loaded on the large gear are compared with the resistance moments of 9000nm input in the previous section. The comparison of stiffness calculation results is shown in the figure. It can be seen from the figure that as the loading torque of the gear increases, the meshing stiffness of the gear also increases nonlinearly, and the fluctuation amplitude of the meshing stiffness of the gear decreases at the same time.

The main reason is that the increase of gear loading force increases the deformation of gear blank, resulting in the increase of the average meshing stiffness. With the increase of load, the meshing coincidence degree of gears increases, so that the meshing impact of gears decreases.