There are two kinds of torsional vibration of bevel gear transmission system: low-frequency torsional vibration and high-frequency torsional vibration. Low frequency torsional vibration is determined by the vibration of the system. For the central bevel gear of aeroengine, because the natural frequency of low-frequency torsional vibration is usually outside the working speed of bevel gear, it is not dangerous to the rim of bevel gear. The most dangerous is the high-frequency torsional vibration whose frequency is the meshing frequency of bevel gear and its frequency doubling, and its vibration source is the change of tooth stiffness in the meshing process. Because the coincidence degree of transmission gears of most aviation accessories is between 1 and 2, a pair of teeth and two pairs of teeth mesh alternately in the working process of gear teeth. When two teeth mesh, the meshing stiffness of bevel gear is about 1.75 times that of single tooth mesh. The change of meshing stiffness is the main excitation source of torsional vibration of bevel gear; In addition, the alternating torque on the gear teeth is another important excitation source of high-frequency torsional vibration.

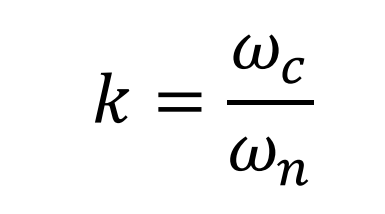

Torsional vibration of the bevel gear is related to meshing frequency of the bevel gear. When the natural frequency of torsional vibration of bevel gear transmission is equal to the frequency doubling of meshing frequency, the torsional vibration of bevel gear transmission increases. Generally, torsional vibration contains multiple harmonics with values of 0.5, 1.0, 1.5 and 2.0. Among them, the strongest harmonic is the harmonic with K value as an integer, i.e. k = 1.0, 2.0, 3.0.

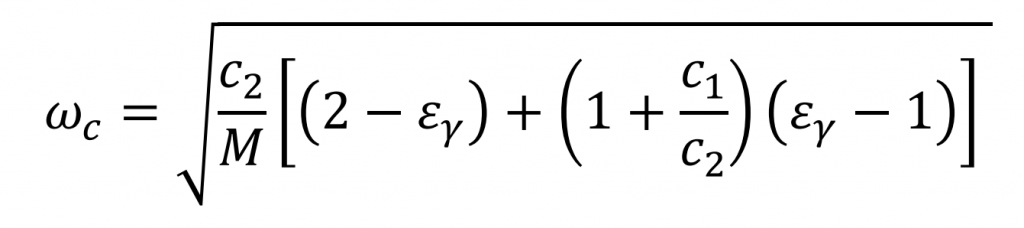

Where: ω C – average natural frequency of torsional vibration of bevel gear transmission device

C1 – unit stiffness of a pair of teeth when entering or exiting meshing,

C2 – unit stiffness of a pair of teeth when a single tooth starts to mesh,

Mass of gear teeth – M,

I1, I2 – moment of inertia of large and small gears;

B – working tooth width of bevel gear;

Db1, DB2 – base circle diameter of pinion and large gear;

εγ— The total coincidence degree of Bevel Gear Considering tooth deformation, machining error and modification;

ω N – meshing frequency of teeth;

N – speed of bevel gear;

Z – number of bevel gear teeth.