Adjusting spiral bevel gear small wheel generating gear pitch cone ΔR01, the table lists the different values of the pitch cone distance of the generating wheel, and studies its influence on the contact condition.

| Serial Number | a | b | c | d | e |

| Pitch cone distance /mm | 154.2470 | 155.6470 | 155.7470 | 155.8470 | 156.2470 |

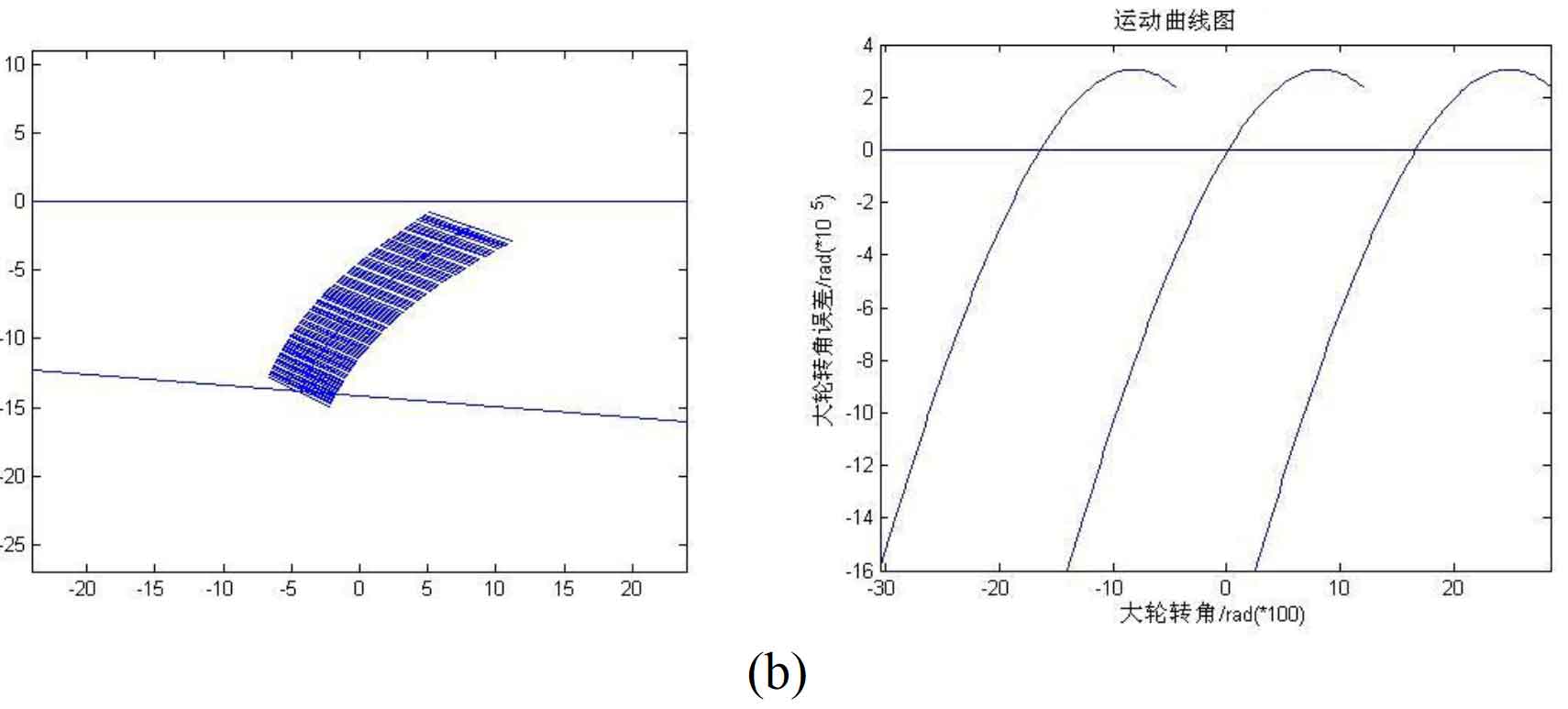

On the basis of the processing parameters shown in the figure, the TCA results of changing the pitch and cone distance of the shaping wheel of the spiral bevel gear pinion by -0.5mm, -0.1mm, 0mm, 0.1mm and 0.5mm respectively. In figure (c), the motion curve and tooth surface contact area of spiral bevel gear are ideal. By observing the change of the contact area, the pitch and cone distance of the shaping wheel of the small wheel are adjusted in the positive direction, which has a very obvious effect on correcting the inner diagonal of the convex contact of the spiral bevel gear small wheel, and has a great influence on the motion curve of the spiral bevel gear pair.

When the pitch cone of the shaping wheel of the spiral bevel gear small wheel is adjusted in the positive direction, the inner diagonal contact phenomenon is reduced, resulting in the outer diagonal; when the pitch cone of the shaping wheel of the spiral bevel gear small wheel is adjusted in the negative direction, the inner diagonal contact phenomenon is intensified, resulting in the inner diagonal; By observing the change of the slope k of the motion curve when the abscissa is 0, the pitch cone distance of the shaping wheel of the spiral bevel gear small wheel is adjusted in the positive direction, the slope k of the motion curve when the abscissa is 0 is less than 0, and the contact area moves to the tooth root; The pitch taper of the shaping wheel of the spiral bevel gear small wheel is adjusted in the negative direction, the slope of the motion curve when the abscissa is 0 is k>0, and the contact area moves towards the tooth top.