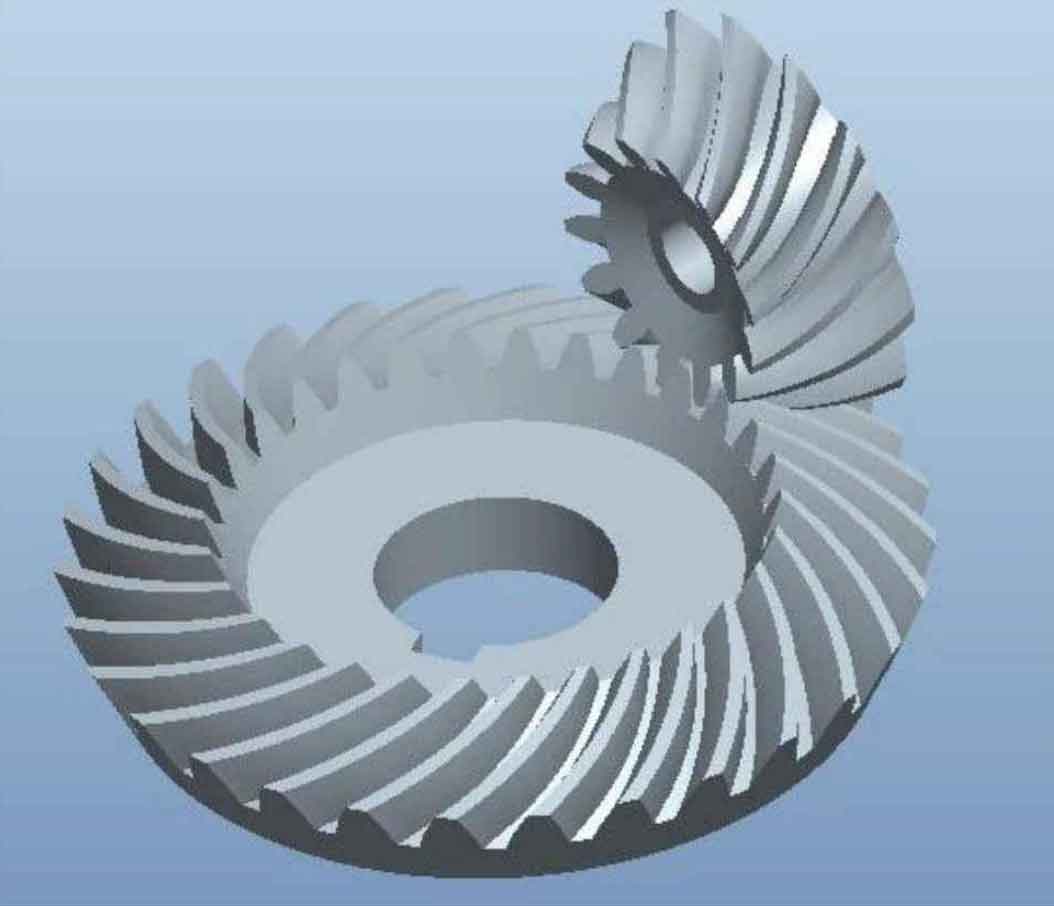

The milling method of hypoid gear is studied. Including the derivation of gear machining equation, machining simulation and machining experiment. The specific research contents are as follows:

1) This paper expounds the basic principle of involute gear generation line cutting method, demonstrates the feasibility of this method for machining hypoid gears, and deduces the machining equations of large and small wheels of hypoid gear pairs.

2) In order to facilitate the machining of hypoid gears, the curve fitting of the cutting area is carried out on the corresponding gear base plane Q. On this basis, the kinematic equation of gear machining is derived, and the NY program is compiled. Based on the existing CNC spiral bevel gear milling machine tool, VERICUT machine tool model is established; In this software, the same cutting tool and gear blank as the actual milling cutter are established, and the NC program is imported into the model for simulation processing, so as to verify the feasibility of hypoid gear processing by generating line gear cutting method.

3) Design the large and small gear blanks of hypoid gears, and finish them into the required shape after purchasing raw materials. Carry out tool setting and relevant adjustment on the CNC spiral bevel gear milling machine tool to complete the gear processing. Finally, the tooth surface is scanned and tested, which proves the feasibility of manufacturing hypoid gear by the method of generating line cutting.