Abstract: This paper focuses on the optimization design of hypoid gear transmissions utilizing a multi-objective genetic algorithm. Considering the significant impact of hypoid gear volume on manufacturing costs and the influence of noise on riding comfort, an optimization model is established with the objectives of minimizing transmission volume and noise while ensuring sufficient load capacity. The results of an example calculation demonstrate a significant reduction in both transmission volume and noise compared to the original design.

1. Introduction

Hypoid gears are widely used in high-speed, high-load, and high-precision transmission systems due to their compact structure, high load capacity, long service life, and low transmission noise. However, they are typically used in devices requiring large transmission ratios, which can lead to larger gear pair dimensions and increased material costs. Additionally, traditional hypoid gear design relies heavily on experience, often resulting in gears that are not cost-effective or performance-optimal. This paper aims to optimize the design of hypoid gears by minimizing both transmission volume and noise using a multi-objective genetic algorithm, thereby enhancing vehicle comfort and reducing manufacturing costs.

2. Mathematical Model for Hypoid Gear Optimization Design

2.1 Determination of Design Variables

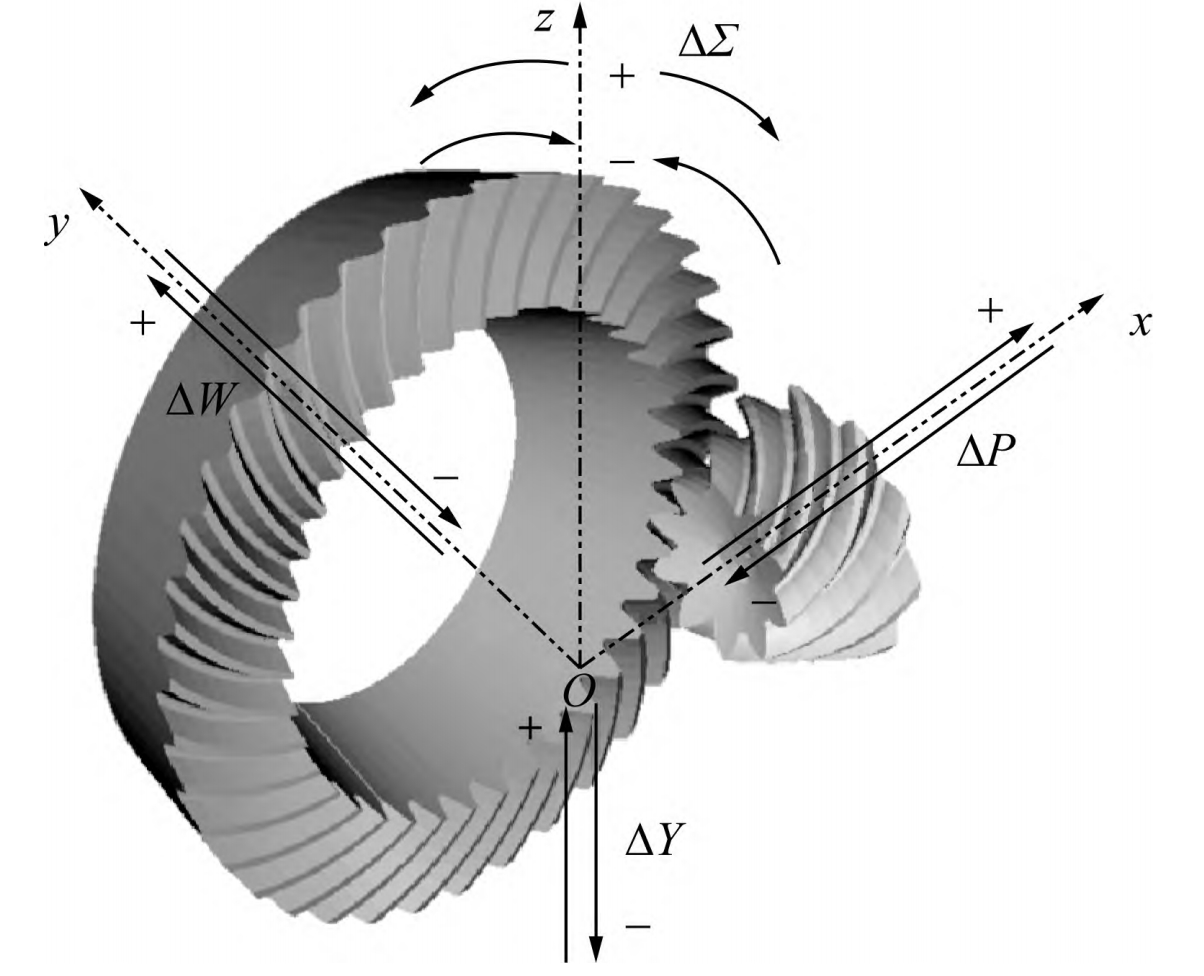

Based on the formulas for hypoid gear volume and gear mesh noise, the independent parameters under a fixed transmission ratio are the number of teeth on the pinion (z1), the large-end pitch diameter of the gear (de2), the face width of the gear (b2), the offset distance of the pinion axis (E), and the spiral angle at the midpoint of the gear (β2). Therefore, the design variables are:

X = [z1, de2, b2, E, β2]T

2.2 Establishment of Objective Functions

To achieve a more compact structure and lower noise, two objective functions are established:

- Minimizing Transmission Volume:

min F(x) = V1 + V2

where V1 and V2 are the volumes of the pinion and gear, respectively, calculated using complex geometric formulas involving the parameters mentioned above.

- Minimizing Noise:

min F(x) = |2 – (k2tanβ – k3/23tan3β)A0πm|

where k2 is a coefficient, β is the average spiral angle of the gears, A0 is the pitch cone distance, and m is the large-end module of the gear, with specific calculation methods detailed in references.

2.3 Establishment of Constraint Conditions

Based on the characteristics and requirements of hypoid gears in practical production, the following constraint conditions are proposed:

| Constraint Condition | Range/Value |

|---|---|

| Number of teeth (z1, z2) | 5 ≤ z1 ≤ 12, z2 ≥ 30, 40 ≤ z1 + z2 ≤ 60 |

| Offset distance (E) | 0.1de2 ≤ E ≤ 0.2de2 |

| Face width of gear (b2) | 4m ≤ b2 ≤ 10m |

| Average spiral angle (βm) | 30° ≤ βm ≤ 50° |

| Contact fatigue strength requirement (SH) | SH ≥ SHmin |

| Bending fatigue strength requirement (SF) | SF ≥ SFmin |

3. Optimization Solution Based on Multi-objective Genetic Algorithm

For multi-objective optimization problems, where there are two or more objective functions, there is no single solution that can optimize all objectives simultaneously. Instead, the optimal solutions typically form a set of solutions known as the Pareto front.

The Non-dominated Sorting Genetic Algorithm II (NSGA-II) is adopted in this paper due to its efficiency and convergence speed. The basic flow of the NSGA-II algorithm is illustrated in Figure 1.

<img src=”https://example.com/nsga-ii-flow.png” /> Note: This is a placeholder image; replace with an actual flowchart of the NSGA-II algorithm.

In MATLAB, the multi-objective genetic algorithm function gamultiobj is used, which employs the controlled elitist genetic algorithm NSGA-II. The function’s parameters include the objective function, number of variables, linear inequality constraints, boundary conditions, nonlinear constraints, and algorithm options.

4. Optimization Design Example

The basic parameters of the hypoid gear pair are as follows: transmission ratio i = 4.1, pinion teeth z1 = 10, gear face width b2 = 30 mm, offset distance E = 20 mm, large-end pitch diameter of the gear de2 = 200 mm, and reference point spiral angle βm2 = 37.14°.

Using the gamultiobj function in MATLAB, multiple sets of solutions are obtained, with the Pareto optimal solution set stored in [x, fval], where fval is the objective function value corresponding to x. The fval values roughly form a spatial curve known as the Pareto front.

<img src=”https://example.com/pareto-front.png” /> Note: This is a placeholder image; replace with an actual Pareto front plot.

Considering both objectives, a point near the difference in coincidence factor ΔεF = 0.05 is selected as the optimization result, where ΔεF represents the deviation of the coincidence factor from the optimal value of 2, which is directly proportional to noise.

| Design Method | z1 | de2 (mm) | E (mm) | b2 (mm) | βm (°) | Volume (mm³) | εF |

|---|---|---|---|---|---|---|---|

| Traditional | 10 | 200.00 | 20.00 | 30.00 | 37.14 | 2.8324 × 10^5 | 2.1552 |

| Optimized | 10 | 196.99 | 19.72 | 26.13 | 38.51 | 2.4725 × 10^5 (-12.7%) | 1.9532 |

5. Conclusion

This paper addresses the multi-objective optimization problem of minimizing both volume and noise in hypoid gears using the NSGA-II algorithm, with optimal parameters calculated using MATLAB’s optimization functions. Compared to traditional design methods, the proposed method demonstrates better optimization results and improved design efficiency and cost reduction. The findings of this study provide a theoretical basis for subsequent design improvements and serve as a reference for the optimization design of other gear transmissions.