Die forging refers to the process that the helical gear blank is formed in the die bore under the action of external force to obtain the forging. In this process, the shape of helical gear blank changes, and the size of helical gear blank will have a great impact on the quality of forging. In terms of precision forging process, it is very important to reasonably design the shape and size of helical gear blank.

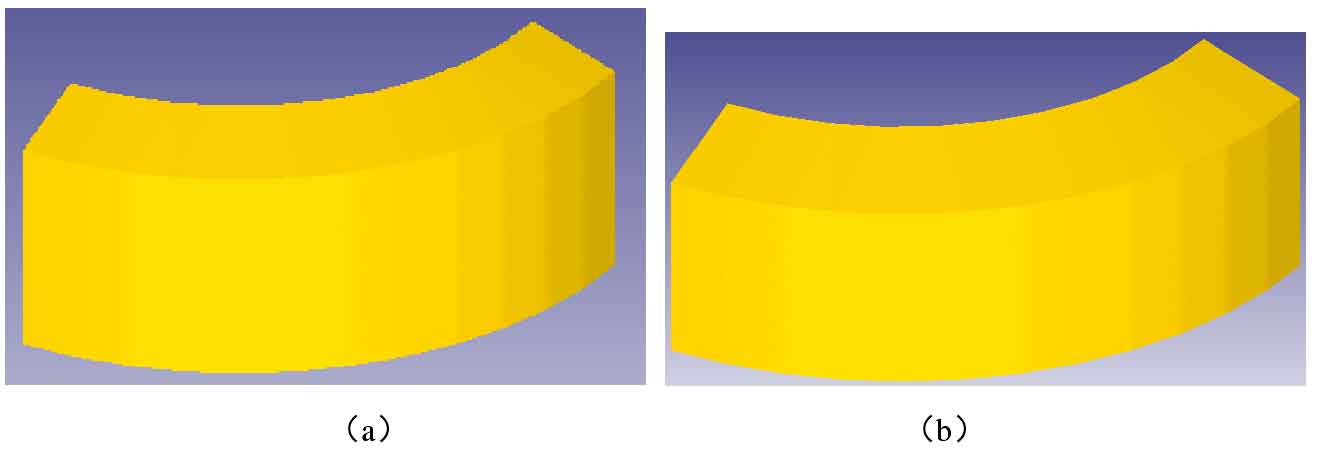

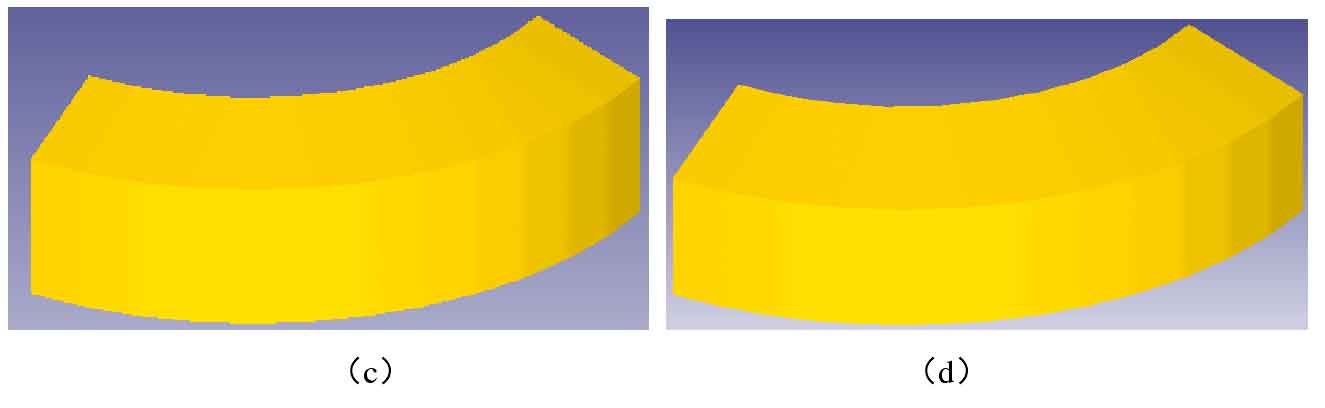

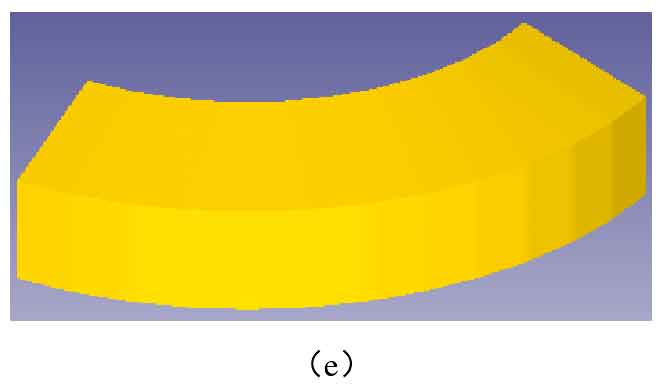

Open the three-dimensional mathematical model of the pre forging of the driven helical gear of the automobile rear axle in CATIA v5r21 software, and the volume of the forging is 3.15 by using the volume calculation tool of the software × 10-4 m3。 According to the three-dimensional mathematical model of the pre forging of the driven helical gear of the automobile rear axle, its outer diameter is 188.3 mm and its inner diameter is 114.32 mm. Therefore, the helical gear blanks with inner diameter of 125 mm, outer diameter of 160 mm, 165 mm, 170 mm, 175 mm and 180 mm and upper surface cone angle of 18 ° are selected for simulation experiment. According to the principle of constant volume in the plastic forming process, after calculation, the height of helical gear blanks should be 47 mm, 41 mm, 36.8 mm, 33.5 mm and 30.8 mm respectively. Its geometric model is shown in figure (a) (b) (c) (d) (E).

For the above five groups of simulation experiments, the main parameter settings in the pre-processing interface of DEFORM-3D are the same. After introducing the helical gear blank and the upper and lower dies, set the forging temperature to 800 ℃, the preheating temperature of the upper and lower dies to 300 ℃, the mesh division of helical gear blank to 100000, the friction coefficient to warm processing, the friction coefficient to 0.25, and the running speed of the upper die to 12.5 mm / s, Conduct simulation operation after setting.