1.Fracture morphology analysis

1.1 macroscopic observation of fracture

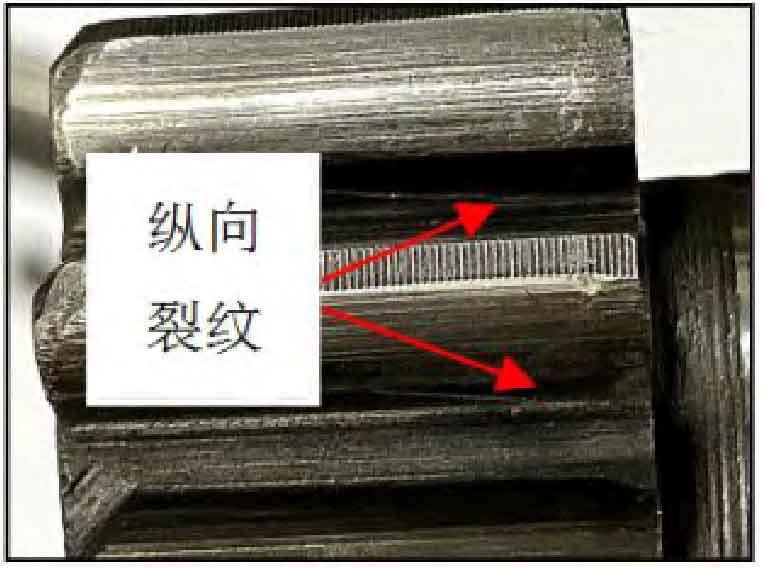

The three teeth of the driving gear of the starting motor are broken from the tooth root as a whole, as shown in Figure 1. Longitudinal cracks of different lengths appear on the tooth root of other unbroken teeth, as shown in Figure 2. There are different degrees of wear marks on the end face of the gear.

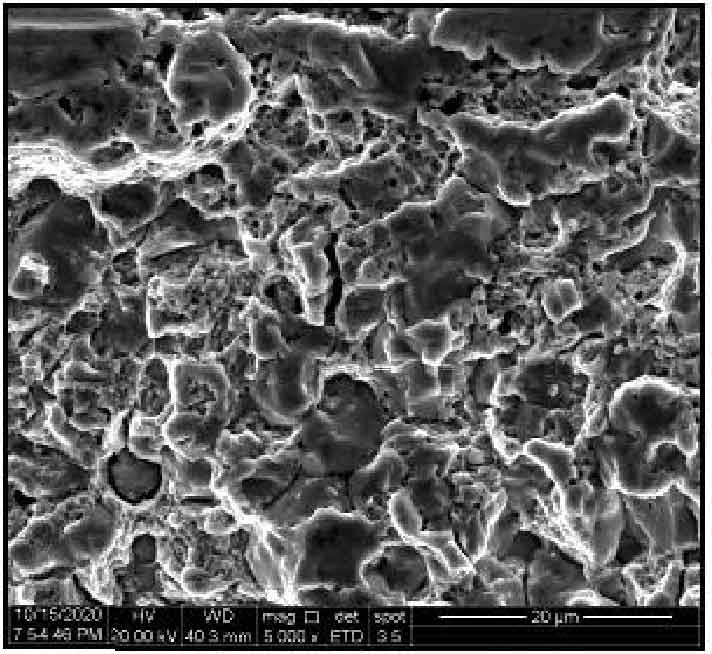

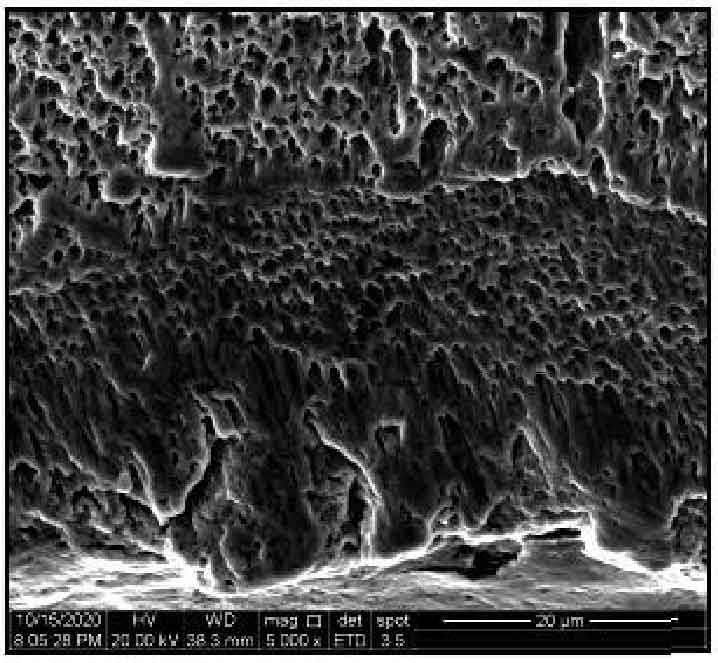

The fracture surface was detected by scanning electron microscope (SEM). The crack source of tooth root was characterized by intergranular dimple, as shown in Fig. 3. The final fracture zone was characterized by equiaxed dimple and shear dimple, as shown in Fig. 4. There was no fatigue crack and no fatigue feature.

2.Chemical composition analysis

According to the GB / T 3077 standard, the chemical composition of the gear meets the requirements of the standard.

3.Metallographic examination and analysis

3.1 gear crack morphology

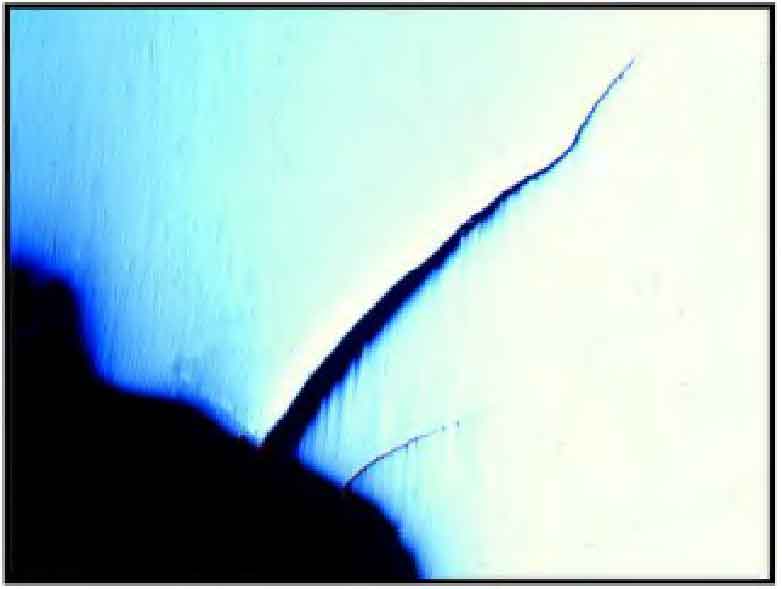

After cutting, grinding and polishing, the fault gear is detected under the optical microscope. The crack originates from the root of the gear. The crack is relatively straight, the starting part is wide, and the tail is sharp. There is a certain angle between the tail of the crack and the surface of the tooth root, as shown in Figure 5; According to the standard JB / t6141.3 “metallographic examination of carburizing heavy duty gears”, the tested microstructure after corrosion is fine acicular martensite + carbide with grade 2 martensite and grade 2 carbide, which is normal carburizing quenching tempering microstructure; No oxidative decarburization was found on both sides of the crack, as shown in Figure 6.

3.2 detection and analysis of non-metallic inclusions

If the non-metallic inclusions exceed the standard, the continuity of the matrix will be destroyed, and the stress concentration point and crack source will be easily produced. The existence of banded structure makes the structure of the material uneven and reduces the plasticity and impact toughness of the material. Therefore, the non-metallic inclusions and banded structure were detected.

The axial matrix of failure fracture gear was sampled longitudinally, and then the non-metallic inclusions and banded structure were detected and analyzed. According to GB / t10561-2005 “determination of content of non-metallic inclusions in steel standard grading diagram microscopic inspection method”, the items of non-metallic inclusions were detected and analyzed, and the grades were A0, B0, C0 and d1.0, which met the requirements of GB / T 5216 “guaranteed hardenability structural steel”.

According to GB / t34474.1 “evaluation of banded structure in steel”, the banded structure is tested and analyzed. The grade is grade 2. The banded structure is generally required to be no more than grade 2, and no abnormality is found.

3.3 detection and analysis of surface and core tissues

According to JB / t6141.3 “metallographic examination of carburizing heavy duty gears”, the surface microstructure is fine acicular martensite + carbide, with grade 2 of martensite and grade 2 of carbide; The microstructure in the core is low carbon martensite + ferrite, grade 3-4. No abnormality is found in the surface and core, which belongs to normal carburizing quenching tempering structure.

4.Mechanical property test

4.1 hardness layer depth detection

The hardness and layer depth of the gear were tested, and the results showed that the surface hardness was 56-60hrc, the core hardness was 40-42hrc, and the layer depth was 0.6-0.85mm, which met the technical requirements.

4.2 tensile and impact test

The tensile and impact specimens are made on the shaft of the gear for tensile and impact tests. According to the national standard GB / t3077, the test data are: tensile strength RM = 1165mpa (≥ 1080mpa), lower yield strength rel = 900MPa (≥ 850mpa), elongation of area a = 13% (≥ 10%), reduction of area ψ= 60% (≥ 45%), impact energy akuz = 75j (≥ 55j), the test results meet the standard requirements.