1. Process analysis of parts

Automobile differential planetary gear is an important transmission part in automobile, and its material is 20CrMnTi. The forming process flow is:

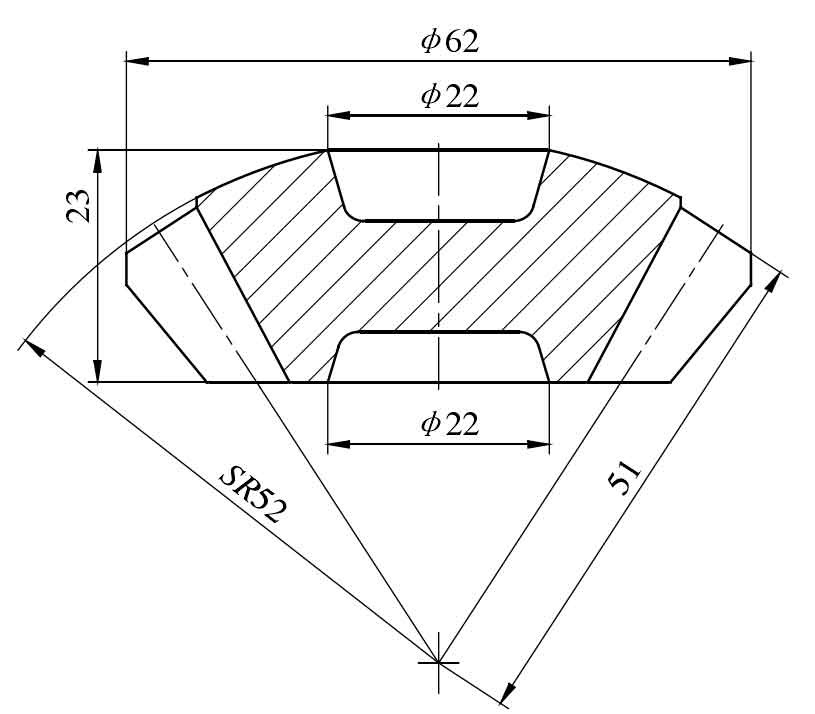

Blanking → deburring and removing surface defects → less oxidation heating → precision forging → surface cleaning → boring and turning back cone sphere → heat treatment → shot peening → grinding inner hole and back cone sphere. Planetary gear forgings are shown in Figure 1.

2. Mold structure design

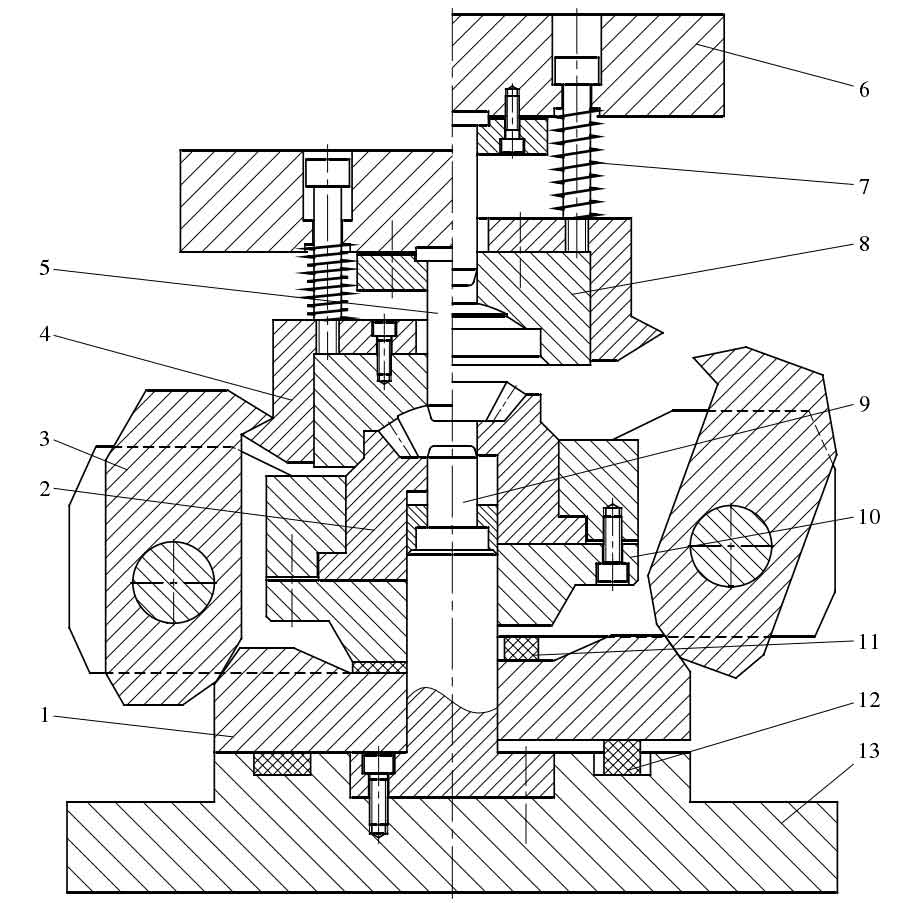

Figure 2 shows the structure of precision forging die for automobile differential planetary gear. The working part of the die is mainly composed of upper female die 8, lower female die 2, upper male die 5 and lower male die 9; The die adopts the matching structure of the upper concave die and the floating lower concave die, and adopts the dynamic locking template to lock the die; The female die is divided into upper female die and lower female die along the parting surface of the forging, which are fixed on the fixed locking template 4 and the lower support plate 10 respectively.

3. Working process of mould

Before the upper and lower dies are combined, the lower die 2 and the lower support plate 10 are at their upper limit position, the blank is placed in the cavity of the lower die 2, and the blank is naturally positioned against the hole cavity wall. The upper die moves down with the slider of the press, and the upper die 8 is aligned with the lower die 2 to form a closed die cavity; Spring 7 is compressed and gives a downward force to the lower die. The upper die continues to go down, the upper punch 5 applies pressure to the blank to make it begin to deform, and the movable lock template 3 moves downward with the lower die and starts to rotate inward around the axis; As the upper mold goes down, the lower support plate 10 compresses the rubber 11, so that the inclined panel 1 moves downward and compresses the rubber 12. At the same time, the movable locking template 3 hooks the fixed locking template 4 to lock the upper and lower molds; When the lower die reaches the bottom dead center, the deformed metal fills the cavity. After the automobile planetary gear is formed, the upper die is lifted. With the separation of the upper punch 5 from the forging, the force acting on the lower concave die 2 and inclined panel 1 will be greatly reduced, and the rubber 11 and 12 will rebound. Under the action of inclined panel 1, the movable lock template 3 will rotate outward, and the upper die, lower concave die 2, lower support plate 10 and inclined panel 1 will rise to their respective upper limit positions. Take out the forging and complete a working cycle.