The conventional drilling rig uses the hoisting system composed of winch, wire rope, crown block and traveling block to drive the hook or top drive device to lift and lower the string. Because the bit pressure can not be provided actively in the process of running in, it is necessary to drill vertical holes when operating horizontal wells and shallow oil and gas reservoirs. The weight of drill string in the vertical section provides the bit with the bit pressure, while the rack and pinion drilling machine can better solve the above problems. Since the 1990s, in order to increase the exploitation of oil and gas wells, the methods of exploiting the remaining wells in old oilfields, horizontal well branch exploitation and multi-objective exploitation of production layers have been widely used. Therefore, it is necessary to develop the mining technology of horizontal well, directional well and extended reach well. The successful development of the multi-functional rack and pinion drilling machine and the continuous innovation of the corresponding technology improve the mining efficiency of the horizontal well and the extended reach well, and solve the problems of trajectory control, bit pressure application and directional control in the mining process of the horizontal well.

1 Rack and pinion drill definition

The rack and pinion drilling machine uses the movement of the rack and pinion in the vertical direction to drive the top drive device for drilling operation. The biggest difference between rack and pinion drilling machine and conventional drilling machine is the composition of lifting system. The rack and pinion drilling machine breaks through the inherent composition of the lifting system of the conventional drilling machine and designs the power unit on the derrick. Its power device replaces the functions of winch, crown block and traveling block of conventional drilling rig, and cancels the use of vulnerable steel wire rope. At the same time, the derrick structure of rack and pinion drilling rig is different from that of conventional drilling rig – rack and guide rail are designed on the derrick. Compared with conventional drilling rigs, the characteristics of rack and pinion drilling rigs are summarized as follows: 1) compact design, small footprint, modular design has been widely used, which improves the market competitiveness of rapid relocation; 2) the drilling depth span of rack and pinion drilling rigs is large, ranging from 2000m to 5000m. It is proved that the rack and pinion drilling machine is not only widely used in shallow oil and gas reservoir, but also has a great space to play in deep oil and gas reservoir; 3) the rack and pinion drilling machine is developing towards automatic and unmanned operation. These rigs are equipped with top drive, pipe processing device, power wool channel, iron roughneck and other equipment, and the number of operators can be reduced to 2-3, greatly improving the drilling safety performance; 4) from the perspective of structure, the winch, crown block, traveling block and other devices are canceled, the drilling equipment is simplified, the vulnerable parts such as wire rope are canceled, and the drilling efficiency is improved. In practical application, when the drill string is lowered, the meshing transmission of the rack and gear provides the bit with WOB, which is conducive to the exploitation of horizontal well and directional well.

2 Development status of rack and pinion rigs abroad

Rack and pinion rigs appeared earlier abroad, and the rig manufacturing equipment has become more and more mature. The most representative features are American augers in the United States, Max Streicher in Germany and TTS sense in Norway.

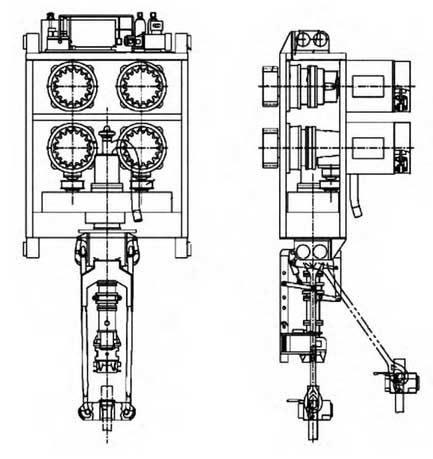

The rack and pinion drilling machine designed by American augers is a vehicle mounted drilling machine, which has no winch, rotary table, cathead, rat hole and cross beam of the drilling floor. This kind of drilling machine has a high degree of intelligence and modularity. Equipped with horizontal vertical hydraulic pipe operation device, not only the operator control in 2 ~ 3, and greatly reduce the floor area. The whole rig covers an area of about 2090m2. The power head device in the lifting system is composed of 6 hydraulic motors and planetary gear reducer. The power head device drives the pulley to move on the derrick. The production rigs include vr-300 rack and pinion single rig in 2007 and vr-500 rack and pinion single rig launched in 2009, as shown in Figure 1.

TTS sense (EDM) of Norway launched the world’s first rack and pinion workover rig in 2001, with the model of 250K. Then in 2005, it launched the finder 250t AC variable frequency rack and pinion land rig. The rack is of modular design and connected by pins to form a rack chain. The derrick adopts a closed mast structure. An inert tensioning wheel is equipped at the top and bottom of the derrick to guide the rack chain, which is driven by six AC variable frequency motors + transmission box + gear wheel fixed at the bottom of the derrick, as shown in Fig. 2 and Fig. 3.

The hoisting system of Max Streicher drilling rig in Germany is quite different from that of TTS sense company in Norway. In the actual drilling process, the gear moves through the teeth fixed on the derrick. In addition, the drive belt fixed on the derrick provides guidance for the power head device. The main models of the rigs are vdd370 in 2005, vdd200 in 2009 and vdd400.

3 Current situation of rack and pinion drilling machine in China

The research on rack and pinion rig in China is less than that in foreign countries. At present, Baoji Petroleum Machinery Co., Ltd., Nanyang Erji petroleum equipment (Group) Co., Ltd. and other manufacturers have successively invested in the independent research and development of rack and pinion drilling machine. Ren Fushen, Wang Wei and other scholars who have studied rack and pinion drilling rig deeply in China focus on the research of hydraulic simulation, multi-body dynamics and similar prototype development of the lifting system of rack and pinion drilling rig, which provides basis and academic guidance for the design of rack and pinion drilling rig. At the same time, many companies and scholars have put forward patent designs on the lifting system or power head device of rack and pinion drilling machine.

The 2000 m full hydraulic rack and pinion drilling machine designed and developed by Nanyang Erji petroleum equipment (Group) Co., Ltd. uses a vehicle mounted chassis, as shown in Figure 5. It is suitable for underbalanced drilling, slim hole drilling and workover, general workover, snubbing operation, old well re drilling and window side drilling, etc., with high operation efficiency. The nominal drilling depth is 2000 m, the maximum hook load is 1580 K N, and the maximum lifting speed is 0.6 m/s. The power head unit is composed of four hydraulic motors + reducers. The power head unit and the top drive unit are designed as a whole to complete the tripping and drilling operations in the drilling process. The motion form of lifting system is to drive the power head and top drive device to mesh with the rack fixed on the derrick through gears. At the same time, the drilling machine adopts the automatic pipe processing device, which can complete the operation of grabbing the drill pipe, transferring the drill pipe to the wellhead, making up, shoring and moving the drill pipe back to the designated position.

The ts40 / 225db rack and pinion drilling machine designed by Baoji Petroleum Machinery Co., Ltd. has a nominal drilling depth of 4000 m. The power head device is composed of 4 sets of permanent magnet electric motors, of which 2 sets of motors are also the power equipment of top drive drilling device, as shown in Figure 6. The whole rig has compact structure, low energy consumption and high transmission efficiency. The movement form of the lifting system is that the gear engages with the rack installed on the derrick, and the guide pulley is equipped to realize the up and down movement on the derrick. The maximum lifting hook load can reach 2250kN, and the maximum lifting speed can reach 1.2m/s. The brake device is equipped with the main brake and auxiliary brake, in which the main brake adopts the disc emergency brake and the auxiliary brake adopts the energy consumption brake.

4 Development trend of rack and pinion drilling machine

The core technology of rack and pinion drilling machine is the development of power head device in lifting system. In the design of power head device, it is not only necessary to meet the requirements of drilling speed at different times, but also necessary to adjust bit WOB according to the actual drilling conditions. The development of rack and pinion rigs at home and abroad shows that the design features of power head device are not single, and the lifting mode of lifting system is also different. According to different drilling conditions, it is necessary to choose the proper driving mode of power head to improve the drilling performance of rack and pinion drilling machine. Through the design and optimization of the power head, not only the performance of the rack and pinion drilling machine can be improved, but also the rack and pinion drilling machine can better adapt to the needs of the drilling site.

The greatest advantage of the rack and pinion drilling machine is that it can provide downforce, which is suitable for the development and utilization of shallow oil and gas reservoirs and horizontal wells, but it is seldom used in vertical or inclined wells. It will be one of the development trends of the rack and pinion drilling machine to reasonably utilize the modular and compact characteristics of the rack and pinion drilling machine, design and develop the rack and pinion drilling machine suitable for various working conditions, and expand the market of the rack and pinion drilling machine.

5 Conclusion

1) The structure and working principle of the rack and pinion drilling machine determine its difference from the conventional drilling machine, that is, it can provide down pressure in the process of running in, which is suitable for the development and utilization of shallow oil and gas reservoir and horizontal well. A lot of research has been done on the rack and pinion rig at home and abroad, and excellent research results have been obtained, and it has been put into use on the drilling site.

2) As the core component of the rack and pinion drilling machine, the power unit has its own characteristics in the design of American augers, Max Streicher of Germany, TTS sense of Norway, Baoji Petroleum Machinery Co., Ltd. and Nanyang Erji petroleum equipment (Group) Co., Ltd. in China, which shows that the rack and pinion drilling machine has strong adaptability and still has great development space.

3) The improvement of hydraulic system, electric control system and rack and pinion technology can promote the development of intelligent and mechanized rack and pinion drilling machine, so we should continue to strengthen the research and application of electric, hydraulic technology and rack and pinion technology.