0 Introduction

Among modern mechanical transmissions, gear transmission is the most widely used form of transmission. Compared with other forms of mechanical transmission, gear transmission can change the speed, torque and direction, and has transmission efficiency With the advantages of high rate, accurate and stable transmission ratio, and large power range, it plays a key role in many fields such as automobiles, machine tools, aviation, and construction. Since entering the industrial age, accidents caused by cracks caused by gear fatigue failure have often occurred, so gear fatigue failure has occurred at home and abroad Research continues. In this paper, the relevant research on the initiation and propagation of gear fatigue cracks at home and abroad in recent years is summarized, and the mechanism of gear fatigue failure, the three types of cracks, the causes and methods of crack initiation and propagation are summarized, and suggestions for future related research are put forward.

1 Gear fatigue failure

In the complex and harsh working environment, the gear needs to withstand great shear stress and impact force due to the high working speed and large load, and will be damaged under the cyclic load condition, which is called gear fatigue failure.

1.1 Main modes of gear failure

In industrial gears with rough surfaces, surface pitting is mainly affected by surface roughness. It causes defects such as residual stress, fatigue, and surface cracking, and some surface pitting can also be caused by chips, machining defects, large notches, and inclusions. Typical failure types include tooth fatigue fracture, work surface wear and pitting, gear surface bonding, and plastic deformation.

Among the types of gear fatigue failures, the most common and most typical fatigue failure forms are contact fatigue and bending fatigue. Fajdiga et al. contact fatigue is defined as a type of damage that causes crack initiation and propagation due to changes in the microstructure of a material under the influence of rolling or sliding contact loads over time. Figure 1 shows an example of pitting on the surface of a gear.

Fig. 1 Pitting pits on gear surfaces

Gear flank contact fatigue is one of the most common causes of gear operational failure due to excessive local Hertz contact fatigue stress. There are many reasons for the mechanism of contact fatigue, the main of which are: local The accumulation of dislocations causes gear bending fatigue, resulting in microcracks; Higher loads lead to bending fatigue fracture of gears; Plastic deformation around the gear is caused by uneven inclusions or other defects in or under the contact surface. The phenomenon of fatigue failure caused by repetitive pulsating bending loads acting on the tooth root is called bending fatigue, and the hardening treatment of the gear surface and the resulting residual stress affect the gear bending fatigue. Single-tooth bending fatigue testing is commonly used to study the load-bearing capacity of a tooth in relation to the bending failure mode. According to numerous test observations, the tooth root is the key location of potential faults, and this area is accompanied by cyclic and variable stresses, and the gear bending fatigue mostly occurs in the tooth root area. Surface pitting is the main manifestation of contact fatigue. Recently The microstructure detection and characterization technology is relatively mature in the study of gear fatigue. Figure 2 shows the macroscopic failure fracture morphology of an AISI 8620 steel helical gear in a bus gearbox. To understand the germination of gear cracks and The cause of propagation was analyzed by scanning electron microscopy (SEM) to analyze the fracture surface and tooth surface of the failed helical gear, and the crack initiation and propagation area under SEM is shown in Figure 3. The observation results show that the fatigue failure of helical gears is caused by pitting corrosion near the end section line of the tooth end face caused by tooth surface misalignment. Here the crack initiates at the tooth active where the maximum tensile stress occurs Analysis of the scanning electron microscope images at the root radius of the side shows that the destructive pitting and spalling zones are located near the nodes. Fatigue cracks originate in these areas of damage and continue to expand. Figure 4

The crack propagation area is shown to have obvious sandy beach signs under the scanning electron microscope, and the fatigue crack has penetrated a large part of the gear before it breaks.

Fig. 2 Higher magnification photograph of the fracture surface of the failed helical gear tooth

Fig. 3 Crack initiation and expansion regions under

scanning electron microscope (SEM)

Fig. 4 SEM displays typical brittle breaks in the crack extension region

1.2 Fatigue injury behavior research

From processing to forming, gear materials require processing techniques such as heat treatment, surface hardening, grinding, etc., therefore, some initial residual stress will be generated in these processes, and the initial residual compressive stress is conducive to fatigue life, while the initial residual tensile stress is not conducive to fatigue life. Overloads and different loading sequences have an effect on the residual stresses, especially the effects of overloads on subsequent cyclic fatigue damage.

A lot of research has been done on the contact fatigue behavior of gears when the gears are working. Table 2 shows a summary of the typical literature on gear contact fatigue behavior published at home and abroad in recent years, mainly according to the effects of tooth load, lubrication state, roughness condition and temperature on gear fatigue。 In order to study the fatigue properties of gears, He et al. calculated and recorded the deterioration of gear materials, the detailed evolution of damage and the stress response during cyclic loading using Abaqus based on continuous damage mechanics. The stress field of the gear contact area and the tooth root area was calculated, and the tooth surface contact fatigue and tooth root bending fatigue were evaluated. The simulation results show that the risk of gear surface contact fatigue failure is much greater than that of gear bending fatigue failure. Wang et al. combined crystal plasticity and continuous damage to describe the fatigue damage behavior of the gear microstructure. The stress-strain response (including shear strain amplitude, maximum normal stress, and normal stress amplitude) obtained by the model is compared, and the microstructure-sensitive model is verified. The verification results of stress-strain response show that the contact fatigue accumulates slowly in the early stage of gear service, increases sharply in the later stage, and the bending fatigue damage is relatively flat in the whole process, and the grain orientation is aligned with the teeth The type of wheel fatigue failure has an important impact.

It is critical to be aware of fatigue damage in a timely manner and to detect fatigue damage on a routine and continuous basis. Most of the current fatigue damage assessment methods are carried out by using the acoustic nonlinearity of ultrasound guided waves, which are detected by acoustic emission signals, and their main purpose is to detect and evaluate the fatigue damage severity of materials and structures, from the embryonic stage of fatigue damage to the gradual growth of macroscopic cracks, and to accurately describe and continuously monitor fatigue damage by establishing a model framework. In order to improve the accuracy of the numerical results of damage quantification based on the second harmonic, a fatigue crack based on guided wave simulation was proposed Compared with the traditional simulation method based on linear crack as the damage model, the nonlinearity of the advanced simulation method in terms of crack length trend and size is closer to the experimental results.

1.3 Factors influencing fatigue strength

The fatigue problem of gears is the weakest link that affects the reliability of the gear transmission system. Studies have shown that for different gears Materials, the factors that affect fatigue performance damage are not the same. The fatigue properties of metal gears are affected by factors such as load, surface roughness and temperature, among which load has been widely studied as an important factor. When using gears, the loads are out of the design range, and the fatigue performance is significantly reduced when the specimen is subjected to periodic overloads of cyclic yield stress levels. In applying different levels of strength to the gears Under load, it is found that when the load is small, the fatigue performance is mainly affected by the stress distribution. As the load increases, the area where the gear can fail expands. For large stress amplitudes caused by load fluctuations, the Brown-Miller-Morrow fatigue criterion is now mostly used Quasi-stress-strain state and prediction of fatigue life. Taking the wind power gear transmission system as the research object, the linear relationship between the torque of the gear input system and the maximum contact stress of the gear is established by using the fatigue criterion, and the random stress is converted into the equal amplitude cyclic stress as the load input variable. Polymer gears have temperature-dependent physical properties, and the temperature rise can significantly reduce the contact pressure of the tooth flank, but at the same time affect the gear fatigue

labor performance, which affects the fatigue life of the gear. It is crucial to consider the effect of temperature on the fatigue strength performance of the gears, even at the same load and speed, the temperature will be affected by the test equipment, the gears Size and shape, surroundings, and cooling and heating rates vary greatly. The effects of different temperature conditions on the fatigue wear of gears were studied, and the results showed that at low temperature (30 °C), The fatigue properties of polymer gears are significantly better. According to the study, in addition to the two main factors of load and temperature, there are other factors such as roughness, such as the slight convexity of the tooth surface Experience has a great impact on gear contact fatigue. The influence of microconvex body parameters on gear contact stress is studied, and the results show that within a certain range, the curvature radius of microconvex body increases, and the contact stress also increases. The contact stress increases with the increase of height, and the height factor has a greater influence on the stress. think, corrosion Damage, such as pitting and the presence of intergranular cracks, can reduce fatigue life, while corrosion pits often form multiple small fatigue cracks that grow together to form larger cracks.

2 Initiation and propagation of fatigue cracks in gears

2.1 There are 3 types of fatigue cracks in gears

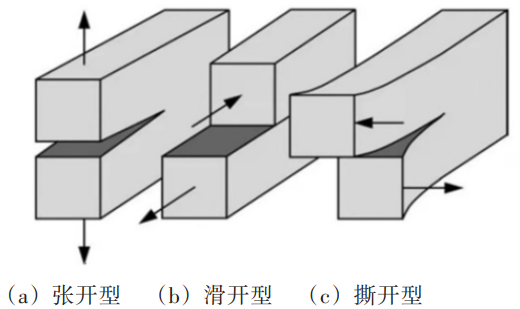

Cracks occur in gears under the action of external forces, and cracks can be divided into 3 types, as shown in Figure 5. Opened expansion cracks (Fig. 5(a)) are cracks produced by tensile stresses perpendicular to the crack surface; Slip-open cracks (Fig. 5(b)) are triggered by a crack perpendicular to the crack surface,

Cracks resulting from slip under shear stress perpendicular to the crack tip; Tear-open cracks (Fig. 5(c)) are cracks that are parallel to the crack surface Cracks caused by tear propagation under shear stress at the leading edge.

Fig. 5 Three basic forms of the crack

It is concluded that in the steady-state crack propagation stage, when the applied load is increasing, the open and sliding cracks will propagate The expansion rate increased. The crack propagation rate in the acceleration stage is basically the same as that of the increased applied load. Under constant load, the crack propagation rate of the gear is higher than that of the open type. Slip-open fatigue cracks typically occur on or below the surface of a component. Slip-open fatigue cracks that start from the surface propagate under the action of air or lubricants, and slip-open fatigue cracks that start from the inside of the surface are usually caused by inclusions in the middle and propagate in a vacuum.

2.2 Analyze the fatigue crack initiation of gears

Cracks are the most common gear failures, and fatigue crack initiation is one of the important stages in the pitting process. Where and how fatigue cracks occur depends on static, dynamic, or thermal loads, the microstructure of the material, the type of stress applied, and the micro- and macro-geometry of the specimen. Compared with the constant amplitude, the changing amplitude of the gear is more likely to initiate cracks than the constant amplitude, and the rate of crack generation is greater. Under the same amplitude loading conditions, the rate of surface crack growth is greater than that of deep crack. In order to make the designed gear safe and reliable, researchers have done a lot of research on the mechanism and propagation path of gear crack initiation, so that people can have a clearer understanding of it.

2.2. 1 Causes

The mechanism of crack initiation has been studied for a long time, but there has been no specific conclusion and it is still in the speculation stage. Since there is no specific description of the cause and process of cracking, there is none

method to carry out specific numerical analysis. During the production of gears, it has been found that the extrusion process may cause some surface defects that may affect the integrity of the material

negative effects. Cracks are generated during extrusion, and the high hardness and low toughness of the alloy promote fatigue crack propagation of existing defects. According to the microscopic analysis of the fatigue area of the gear, it can be clearly found that the fatigue arc and radial fringes are distributed in the fatigue source area and the expansion zone respectively, and there are tooth surface machining knife marks near the initial crack. Therefore, it is determined that the cause of the crack is due to the initial knife marks of the tooth surface machining, and the crack gradually expands to the point of fracture under the continuous cyclic load. The three-dimensional finite element method was used to study the initiation of gear cracks, and the results showed that the maximum stress existed at the root of the gear teeth, and the initial crack appeared at the place where the stress value was the largest. A two-dimensional plane strain finite element mesh was established to evaluate the stress at each point of the gear teeth in each load cycle, and combined with the finite element analysis, the risk of cracks in different parts of the gear was calculated, and the analysis results showed that the tensile stress caused by surface hardening led to high fatigue stress in a large area inside the gear.

2.2. 2 Detection methods

Whether it is for fracture mechanics research or safety research, the means and methods to measure the initiation, propagation rate and direction of cracks are very important. In a large number of studies, researchers have established: Different models detect cracks caused by fatigue movements of gears based on the distribution of residual stresses, stress-strain curves, etc. The study was carried out by mapping the distribution of residual stress and hardness at different distances on the gear surface

the gear fatigue crack initiation area; Combined with the distribution of fatigue strength and working stress from the surface to different depths, it is easy to determine the areas most prone to fatigue and the location of fatigue crack initiation by varying the applied load. In order to quickly predict the crack propagation path, a factorial design method for gear bending fatigue simulation was proposed. A two-dimensional boundary element model with assumptions of linear elasticity is used to design the factorings In the experiment, the bending fatigue damage was modeled using a polynomial function. The established prediction model can quickly establish the crack trajectory of thin-edge gears at any number of cycles. The reliability of damage (fault) definition is improved by processing the time-frequency vibration signal related to the rotational speed in the time-frequency analysis. According to the predictions, there will be some characteristic changes in the signal measured at the time of the crack that should increase the number of sidebands in the spectrum. At present, the analytical model of good gear stiffness meshing calculation has been improved, and the analytical model method is compared with the finite element method The results are in good agreement and the calculation time is shorter. An analytical grid stiffness calculation model with non-uniform distribution of root cracks along the tooth width was proposed, which could well predict the tooth cracks generated in the early stage of the spur cylindrical gear pair. Through the case study, it can be seen that the statistical index of crack-related dynamic characteristics in the gear transmission system is more sensitive to the propagation of the crack along the tooth depth than the propagation of the crack along the length. Among the three statistical indicators (inter-peak, kurtosis and crest factor) used in this paper, kurtosis had the least sensitivity to crack propagation. It was found that the gear crack is closed in the non-service state, but in the working state, the crack is open; An improved calculation model of the meshing stiffness of the tooth surface of the gear with cracks was proposed, which considered the change of the effective compression cross-section of the crack tooth surface and the neutral layer offset caused by the crack opening. For large cracks, the influence of the bending stiffness change caused by the neutral layer shift on the mesh stiffness cannot be ignored.

2.3 Analyze the causes of fatigue crack propagation in gears

2.3. 1 Extension Methods

Fatigue crack propagation prediction is an effective tool for estimating the remaining useful life of structural components before failure. After a crack occurs in the gear, defects in the material, pre-cracks and cyclic loads can easily lead to undetected defects The crack propagates into any shape in any direction. There are several numerical simulation methods for gear fatigue fracture, including the finite element method, BEM, meshless, and extended finite element method. In recent years, the simulation of crack propagation has increasingly changed from 2D to 3D, and the finite element method and extended finite element method are mostly used to simulate and predict the crack propagation of gears. Moes et al

It is found that the extended finite element method can predict the crack propagation rate, the number of failure cycles, the crack shape and the final size of the crack, which is basically consistent with the morphology of the test results, which verifies the reliability of the method. Using the extended finite element method,The influence of the initial crack geometry and cyclic load factors on the fatigue fracture behavior of the gear teeth was analyzed, a two-dimensional finite element model of a pair of teeth was established in Abaqus, and a crack was pre-set at the root of the tooth, and the simulation model and meshing were shown in Figure 6, and the crack propagation direction was determined according to the maximum stress criterion. According to the expansion finite element simulation model, it is found that the initial position of crack initiation has a great impact on the direction and rate of crack propagation

The length of the initial crack affects the crack propagation rate to a certain extent. The time-varying meshing stiffness and crack propagation behavior of the spur cylindrical gear were determined by the extended finite element method, and the results showed that the crack propagation The spread path is strongly dependent on the crack origin. The results of cyclic loading conditions were analyzed using the finite element method, and then the virtual crack propagation method in the finite element method was used to simulate the initial crack to the surface the fatigue crack propagation process of pit formation; In order to obtain the number of loading cycles required for the extension of the initial crack length from the initiation of the crack to the critical length, the relationship between the stress intensity factor and the crack length is given. The path and rate of crack propagation under applied load are studied

Important methods in the analysis of fracture mechanics and are based on the assumptions of linear elastic fracture mechanics. Adopt a principal elastic fracture based on it The two-dimensional finite element method of mechanics or linear elastic fracture mechanics predicts the crack propagation path at the root of the gear tooth. When the crack length is 10%, 20%, 30%, 40% and 50%, respectively, the corresponding vibration signals are recorded. The experimental results show that the multi-pulse rescaling time synchronization averages as well.

2.3. 2 Reasons for expansion

In the process of crack propagation, the stress and the inhomogeneity of the material structure will affect the crack propagation rate and the deflection of the propagation direction, and the process of crack deterioration is usually related to the microstructure change of the material. The stress intensity factor is particularly closely related to the crack propagation of gears, which is based on the linear elastic theory and reflects the cracks The strength of the stress field at the tip. Therefore, it is necessary to numerically simulate the stress intensity factor and study its influencing factors. It is concluded that when the stress intensity factor K is within the range of the critical stress intensity factor KIC, the crack propagation rate remains stable. Figure 7 shows the curve of the stress intensity factor K as a function of crack length a. As can be seen from Figure 7, the crack expands to 2. Before 5 mm, the increasing trend of the stress intensity factor was steady. When the crack length exceeds 2. After 5 mm, the stress intensity factor K exceeds the critical point of the material The value KIC=2 840 N·mm-3/2 and increased sharply, the crack spread rapidly, and the teeth broke. Thirumurugan et al It is believed that in the actual gear operation, the magnitude and position of the force will change with the rotation of the gear, and the influence of the moving gear load on the service life of the gear is studied by using the critical plane damage and finite element theory model, and the number of stress cycles required for fatigue crack initiation is determined. The numerical solution of the infinite elastic plane including macroscopic cracks and arbitrarily oriented microcracks is given, and the stress intensity factor, stress field and strain energy density near the crack tip are obtained, and the influence of microcracks on macroscopic crack strength factors is analyzed. The results show that the influence of microcracks on the macroscopic crack strength factor gradually weakens with the decrease of the length of the microcrack or the increase of the distance between the microcrack and the macroscopic crack. Microcracks increase the strength factor of macroscopic cracks in one direction and decrease them in the other direction.

Fig. 6 Double tooth models for gear engagement and boundary conditions

Fig. 7 Change of the stress strength factor K with the crack length a

In addition, there are also the effects of crack surface roughness, crack offset, crack tip distance, and relative position of cracks on crack propagation. By calculating the value of the stress intensity factor K, the value of K is analyzed relative position, thus simulating the propagation behavior under crack interaction. In the paper, a fracture toughness criterion is mentioned, that is, when the value of the maximum stress intensity factor at the crack tip is greater than the value of the stress strength factor at fracture, the crack will propagate. The effect of rim thickness on gear cracking in different use areas was studied The effect of grain propagation life and behavior, and the effect of different rim thickness on the crack behavior of asymmetrical tooth profile gear was investigated. Perform a static-stress analysis in Ansys Work⁃bench to determine the start point of the crack and define the maximum stress point as the start point of the crack; Again, in Fatigue crack propagation analysis was performed in Ansys Intelligent Crack Propagation. The results show that the fatigue strength of asymmetrical toothed gears is much higher than that of symmetrical toothed gears.

2.4 Life estimation study of gear fatigue test

Tooth surface pitting caused by tooth surface fatigue

It occurs in the early failure period, and the failure rate of tooth surface pitting is high. It is believed that the crack initiation period accounts for most of the service life, and the influence of the moving tooth load on the fatigue life of the gear is studied The surface method can not only predict the fatigue life of the gear, but also predict the direction of crack initiation. A crack propagation trajectory generation method based on 3D boundary element method was proposed, which was obtained by Franc 3D method

The influence of gear parameter change on the crack propagation path of the root of the spur cylindrical gear, and the crack propagation path was obtained by using the maximum tangential stress crack propagation criterion, and then the remaining life of the gear fatigue crack was estimated. The results show that the larger the pressure angle, the smaller the fatigue life. Lower up The start angle is beneficial for improving fatigue life.

3 Methods to avoid fatigue cracks in gears

There are many ways to avoid gear cracks at the root, with some studies focusing on reducing bending stress levels and thus increasing gear strength. The cause of gear crack initiation is not only work-in-progress In addition to the fatigue load in the middle cycle, a large part of the reason is that in the process of gear manufacturing, the defects in the processing technology cause the concentration of residual stress on the tooth surface. Therefore, in the process of gear processing, the roughness of the gear surface should be reduced and the hardness of the gear tooth root should be enhanced.

The influence of residual stress during machining on the strength of gear roots is minimized. In addition, we can also start from the selection of materials and the design of gears, and use innovative gear materials to design new ecological gears. Traditional materials such as engineering plastics can be replaced with lower-cost materials, and the optimal rim thickness can also be selected to increase the root stress of the gear. by carburizing or coating After machining, the contact surface hardens to extend

Long gear life is standard practice. Chromium coatings are a way to extend the life of steel gears, and these coatings are extremely hard and chemically inert. The friction factor is reduced, i.e. the gears are better lubricated and therefore the service life is increased. When the gear is fatigue damaged, the use of appropriate technology to repair the gear can effectively prevent the occurrence of failure and catastrophic accidents, and can prolong the fatigue life of the cracked gear. protect The maintenance of the technical system (gear unit) in the most suitable working condition is the purpose of maintenance

However, the purpose of modern maintenance is not only to eliminate failures, but also to define the potentially dangerous stages of sudden failures in the operation of the system. The carbon fiber reinforced polymer reinforcement system can significantly improve the fatigue life of steel components. In addition, recent studies have shown that the use of prestressed unbonded carbon fiber reinforced polymer reinforcement systems can further reduce the fatigue crack growth rate and promote crack arrest. In the future technology of detecting gear fatigue faults, we can focus on signal detection, study the amplitude modulation effect of variable speed, and find the corresponding modulation scale, so that the filtering process is more stable, and it is easier to detect and analyze the problems existing in gear work. At the same time, some new methods can be better combined with monitoring crack initiation and propagation, such as the DC voltage fluctuation method, which can monitor the whole process of crack propagation and measure the crack propagation rate in real time, which is based on electricity

The principle of monitoring voltage changes caused by resistance changes.

4 Summary

The manufacturing industry has developed rapidly in recent years, and the performance requirements for all aspects of gears are getting higher and higher. Under the continuous cyclic load of internal and external forces, the gear will fatigue, crack initiation, and eventually lead to fracture. Cracked

There are three types: open type, sliding type and tear type, and the causes of different crack types and the rate and direction of propagation are very different under different working conditions. Cracks have become the most common failure of gears, and many research tests have been done on the initiation of cracks. The causes of crack initiation depend on the static, dynamic or thermal load, the selection and processing of the material, the type of action of the external working conditions, etc. Under the action of continuous internal and external forces, the crack of the gear propagation. There are many methods to study gear crack propagation, among which numerical simulation methods include finite element method, boundary element method and extended finite element method, and in recent years, more and more extended finite element methods have been used. The method of crack propagation involves many factors that are utilized In this method, the influence of the shape, length and cyclic load of the crack in the initial stage on the crack propagation behavior is analyzed. The estimation of the life of gears under fatigue tests provides a theoretical basis for predicting the probability of gear failure and increases reliability. Some of the test methods and theoretical results are effective means to predict the crack initiation and life of gears. Avoiding cracks is the main measure to ensure the efficient and safe operation of gears, from the root point, the microstructure and mechanical properties of gear materials are particularly important, through gear damage detection algorithms, such as average comparison number algorithms The relationship between the evolution of microstructure, fatigue damage and mesomechanical behavior in the process of gear contact fatigue was deeply explored. When the fatigue damage occurs in the gear, the crack is monitored by signal detection and other technologies, the propagation rate and direction of the crack are measured in real time, and the technology is used to repair the gear crack and prolong the service life of the gear. Although the anti-fatigue manufacturing technology of gears still faces many problems that need to be overcome, in the context of the country’s vigorous implementation of innovation-driven development strategy, in order to obtain advanced and ideal comprehensive performance of gears, it is necessary to integrate modern heat treatment technology, surface strengthening technology and other disciplines With the combination of materials, processes and equipment, the future advanced manufacturing technology will continue to progress and make a qualitative leap.