As an important navigation facility of the Three Gorges Water Control Project, the ship liftOne of the important components of the Three Gorges Project, mainly for passenger ships,Cargo ships and special ships provide fast passage through the dam, with a maximum size of3000-ton, total lifting mass of about 15,500 t, maximum lifting height113 meters,gear shaping the largest and most technically difficultThe Three Gorges ship lift uses a rack and pinion climbing type fullBalance vertical lifting structure, which is driven by 4 sets of open gear and rack meshingThe vertical lifting of the ship lift is realized by moving the rack and pinion.The modulus is up to 62.667 mm, the rack tooth width is 810 mm, gear shaping and the length of a single section is4,705 mm, mass 10.6 t, each rack consists of 26 rack groupsThe total laying height is over 120 m, with large quantities of engineering work and high manufacturing requirements.high cost and difficulty in replacement. Therefore, ensuring theThe service reliability of the transmission system is essential to ensure the safety,gear shaping Reliable and efficient operation is of great significance.

During the construction and trial operation of the Three Gorges ship lift project, domestic counterpartsThe design,gear shaping construction, and operation and maintenance units focus on the overall structural design of the ship liftA large amount of research has been carried out on the service performance evaluation of gears and racks.According to the structural principle of the Three Gorges ship lift, system analysisThe gear rack load under 24 operating conditions during the operation of the ship liftSize and force direction,gear shaping and determined through theoretical analysis and simulation experimentsThe root bending stress of the gear rack of the ship elevator under rated load is calculated.For the gear rack and pinion transmission system of the Three Gorges ship liftEstablished a low-speed heavy-duty gear rack elastohydrodynamic lubrication model and analyzed differentSpecification for changes in tooth contact lubrication status under operating conditions and influencing factorsLaw. Based on the lubrication state of tooth contact and simulation experimentsAnalyzed the tooth surface adhesion loss of low-speed heavy-duty open gear rack and pinion transmission systemCold wind insurance.gear shaping Calculated based on Archard’s wear formulaThe tooth surface wear during the gear rack meshing transmission process of the Three Gorges ship liftIts influence on the time-varying meshing stiffness of the gear teeth, and its calculation results indicate that the teethThe tooth surface wear of the gear rack is extremely slight, at 3 × Under 105 engagement timesThe maximum wear depth is less than 25 μ M. Through finite element analysisA simulation comparative study was conducted on the contact strength of the driving gear and rack of the Three Gorges ship lift considering the effects of tooth surface modification and axis deviation.Based on the dynamic simulation of the gear rack transmission system of the Three Gorges ship liftThe load spectrum obtained was used to analyze the root bending fatigue life of the driving gearLife prediction, gear shaping the results indicate driving under a false load depth of 5 cmThe fatigue life of gears is 3.816 × 107 cycles, meeting the actual requirementsUse requirements.

The result is to ensure the construction and reliability of the Three Gorges ship liftThe operation provides effective technical support, gear shaping however, due to the previous lack of domestic technologyThere is a lack of operation and maintenance data for such large ship elevators,gear shaping and previous research mainly relied onBased on the rated load calculated during the design process of the ship liftI am well aware of the changes in operating load during the actual use of the machineLess, gear shaping therefore it is difficult to assess the fatigue life and reliability of the gear and rack of the ship elevatorAccurately evaluate based on performance. Fatigue life based on measured load spectraCalculation is the current field of engineering technology that focuses on the durability and feasibility of componentsThe main technical means of sex research. Three Gorges Ship Lift Since 2016Since the annual trial navigation,gear shaping more than 30000 safe trips have been completedStable operation, accumulating a large amount of valuable operational data and information, enablingWe need to develop a load spectrum for the gear and rack of the ship elevator to assess its fatigue lifeAccurate evaluation becomes possible.

Statistical analysis of the measured operational data of the Three Gorges ship liftAnalyze and study the gear and rack loads of ship elevators under different operating conditionsThe variation pattern and its calculation model, based on the different strokes of the ship liftCompile gear and rack load spectrum based on the distribution law of water depth in the ship compartment,gear shaping and analyze itCalculate the fatigue life of gear and rack, and combine it with full-scale simulation in the early stageTest results verify the service of the gear rack transmission system of the Three Gorges ship liftReliability.

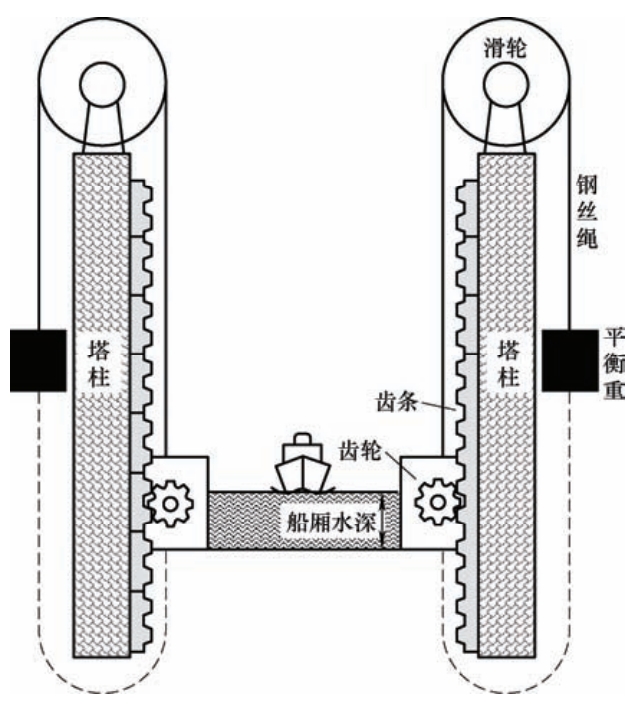

The Three Gorges ship lift is a gear rack climbing fully balanced vertical ship liftMachine, mainly composed of tower pillars, ship compartments, steel wire ropes, gear shaping pulleys, counterweightsComposed of a balance chain and four sets of gear and rack drive devices, its structure is as followsAs shown in the figure. When the ship lift is in operation, the weight of the cabin is mainly balanced byHeavy offset, driving gear and rack are mainly used for motion control of ship compartmentsCompensate for the unbalanced weight difference between the cabin and the counterweight, gear shaping overcome the acceleration and deceleration inertia forces and frictional resistance during the operation of the cabin.

The length and width of the ship lift compartment of the Three Gorges project are 131 meters and 18.4 meters, according to the standardThe water level height is 3.5 meters, and the maximum allowable false load during actual operationThe gear and rack directly generated by the unit false load water depth with a water depth of ± 10 cmThe load Fh is approximately ± 23 622 kN/m. When the water depth in the cabin is 3.5 meters,gear shaping In theory, the overall weight of the cabin is consistent with the counterweight, but due to the actualManufacturing and installation errors, there is an unknown initial weight between the twoQuantity difference, recorded as Δ G. gear shaping The frictional resistance during the operation of the cabin includesThe frictional force between the pulleys and the rotational components of the drive systemFriction force, etc., whose combined force is denoted as Ff, always in the direction of the ship’s compartment movementTo the contrary. gear shaping The designed operating speed of the ship lift is 0.2 m/s, and the acceleration/deceleration during normal starting and braking processes is 0.01 m/s2For ship liftThe total mass of the entire ship compartment and its counterweight is about 31000 tons, and its inertial forceApproximately 310 kN (the influence of false water depth can be ignored), while the ship liftThe inertia load generated by the rotational inertia of the driving system is close to 990 kN,The total inertial load Fa generated by the two approaches 1300 kN in its directionOpposite to the direction of acceleration in the cabin.

Record the load of the ship lift in a downward direction as positive, and drive the gearsThe tangential force Ft generated by meshing with the rack is positive in the upward direction (gearIf the lower tooth surface meshes with the upper tooth surface of the gear rack,gear shaping the Three Gorges ship lift will experience different errorsThere are 12 different force balance states under water depth and operating conditions.

To analyze the gear rack load during the operation of the Three Gorges ship liftChange pattern, including the speed and torque of the motor (1 # to 8 # motors) driven by the ship lift system, as well as the torque of the synchronous shaft system (1 # to 4 # synchronous shafts)Drive point displacement and cabin water level height as core data for acquisitionSet. The above data was collected and extracted by the ship lift operation and maintenance department of the Yangtze River Three Gorges Navigation Management Bureau, with a sampling period of 1 second, gear shaping for a total of collection105 days of operational data, including nearly 2400 valid trips.

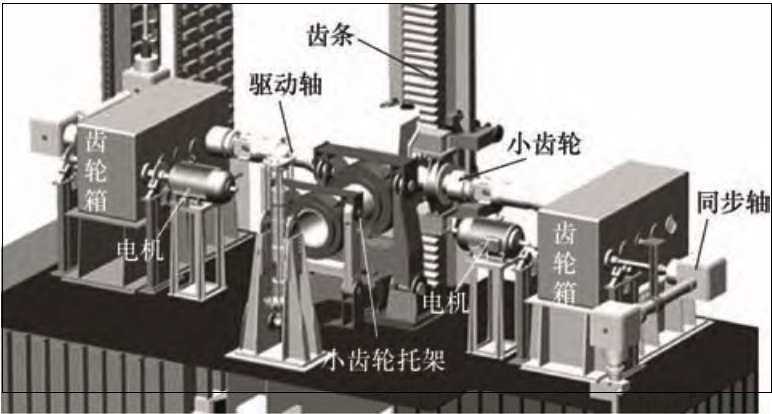

The gear rack and pinion transmission system of the Three Gorges ship lift has a total of four sets of gear teethStrip pair (drive unit),gear shaping each drive unit is driven by 2 motors through gearsAfter deceleration and torque increase, the flow converges on the small gear shaft. Four drivesThe moving points are connected to each other using a “I-shaped” mechanical synchronous shaft systemConnect to ensure synchronous operation and output compensation of each driving point.Therefore, the gear rack load during the operation of the ship lift can be determined by the various drivesCalculate the motor torque and synchronous shaft torque at the moving point, such asAs shown.

The depth of the cabin and the operating status determine the gear rack load of the ship liftThe main influencing factors of lotus. Figure 3 shows the water depth bars in different compartmentsGear and rack loads during several operational processes of the Three Gorges ship liftChange curve. From the graph, it can be seen that a complete ship lift operationThe driving process includes three stages: acceleration, constant speed, and deceleration, gear shaping among whichDuring the constant speed operation stage, the load on the gear and rack remains basically constant; AcceleratingDuring the deceleration phase, the load shows a sharp increase and dramatic change in its direction of operationReduce the variation, and its amplitude is basically the same.gear shaping In addition, gears and racksThe overall load changes from negative to positive as the depth of the ship’s compartment increases and shows a clear trendThere is a clear upward trend. It should be noted that the gear rack load changes from negative to negativePositive only represents the transformation of the meshing tooth surface from the lower tooth surface of the rack to the upper tooth surface,gear shaping therefore,The magnitude of its load is essentially not dependent on the operating state of the ship’s compartment or the depth of the compartment’s waterTransforming into a fixed single trend pattern of change.

The total load of the gears and racks of the Three Gorges ship liftFt is the gear rack load Fi (i=1-4) at the four driving pointsTogether. There is no significant difference in operating load between different driving pointsUnder the item, it is evident that there is Fi=Ft/4, which can also be considered as a function of the depth and lift of the ship’s compartmentA deterministic load that reflects changes in the operating state of a ship’s machinery. However, gear shaping in terms of dataDuring the analysis,gear shaping it was noticed that during the operation of the ship lift, although the gear and rack assemblyThe overall load remains stable with no obvious load fluctuations, but onlyThe gear rack load at each driving point revolves around the average load Ft/4It shows a cyclical fluctuation trend,gear shaping and the fluctuation trend between pairwise is always maintainedSame or opposite.

Each driving point during the operation of the ship liftThere is a significant load deviation between them, using the form of formula (1)The nominal average load Ft/4 is difficult to accurately describe the actual condition of gear and rackLoad conditions. gear shaping The original cause of the load deviation of the gear and rack at each driving pointBecause it may come from the movement of various driving points during the operation of the ship liftThe analysis of the deviation and dynamic meshing characteristics of gears and racks will not be expanded here.

The above analysis shows that the gear rack load during the operation of the Three Gorges ship lift mainly depends on the water depth of the ship compartment,gear shaping the operating status of the ship compartment, and the random load deviation. Among them, the depth of the ship’s compartment is a random variable that varies with the different operating strokes of the ship lift; The operating status of the ship compartment is a deterministic variable with a fixed time sequence and proportion within each operating stroke; gear shaping Load deviation Δ Fti is a random variable at each operating time of the ship lift.

Due to time and cost constraints, the measured operating data of the Three Gorges ship lift currently extracted is only a small segment of its entire life cycle. In order to accurately evaluate the fatigue life of the gear rack transmission system of the ship lift, short-term loads need to be extrapolated to obtain a load spectrum representing the entire life cycle. gear shaping However, unlike other studies that directly analyze the actual load of a certain type of equipment or component, the load distribution characteristics of the Three Gorges ship lift gear rack mainly depend on the changes in the water depth of the ship chamber during different operating journeys of the ship lift (the normal distribution characteristics of gear rack load deviation do not change with sample size). Therefore, when establishing the load spectrum of the ship lift gear rack, gear shaping the distribution of water depth in the ship chamber should be extrapolated.

When extrapolating the water depth of the ship lift compartment, it is possible to simplyThe known statistical results should be extrapolated proportionally, but after reasonable parameter estimation of their distribution characteristics, the obtained probability density function should be used to extrapolate the target distribution frequency throughout the entire design life cycle.Due to the complex changes in the water depth of the compartments during different journeysMiscellaneous,gear shaping its distribution has obvious bimodal characteristics, and commonly used statistical models cannot accurately describe it. Therefore, non parametric statistical methods are used to fit the measured data of ship compartment water depth, making the extrapolation results more accurate.gear shaping Non parametric statistics are suitable for statistical problems where the overall distribution form is unknown or its probability distribution is difficult to describe using parameterized distribution functions. They are widely used in the compilation of load spectra for various types of equipment and components.

(1) The load on the gears and racks of the Three Gorges ship lift is determined by the water depth in the receiving compartmentDeterministic loads for operational state control and compliance with N (0, 1552))Normal stateComposition of random load deviations in distribution; Based on the measured operating number of ship elevatorsA gear rack load calculation model has been established based on fitting.(2) Using Gear and Rack Load Calculation Model and Ship Lift ChamberA load spectrum for the gear and rack of the Three Gorges ship lift was compiled based on the distribution law of water depth;For the drive gear and central rack, the load is mainly concentrated under the gearThe tooth surface and the tooth surface on the rack, for the top and bottom racks,gear shaping gear shaping the load is divided intoDo not focus on the lower and upper tooth surfaces of the rack, and their load conditions are relatively lowThe central rack is more prominent.(3) Calculated the accumulation of gears and racks in various regions based on the load spectrumAccumulated fatigue and strain injury, for the bottom rack with the worst loading conditionsOn the upper tooth surface, the calculated rolling contact fatigue damage degree only reachedone point three six × 10-5, the actual fatigue life of the corresponding rack can reachthree point one one × 1011 trips far exceed the designed lifespan of the rack.(4) The simulation test results of full-size gear and rack have verified the Three Gorges projectThe gear rack and pinion transmission system of the ship lift does not exist within the design life cycleRisk of fatigue damagegear shaping .