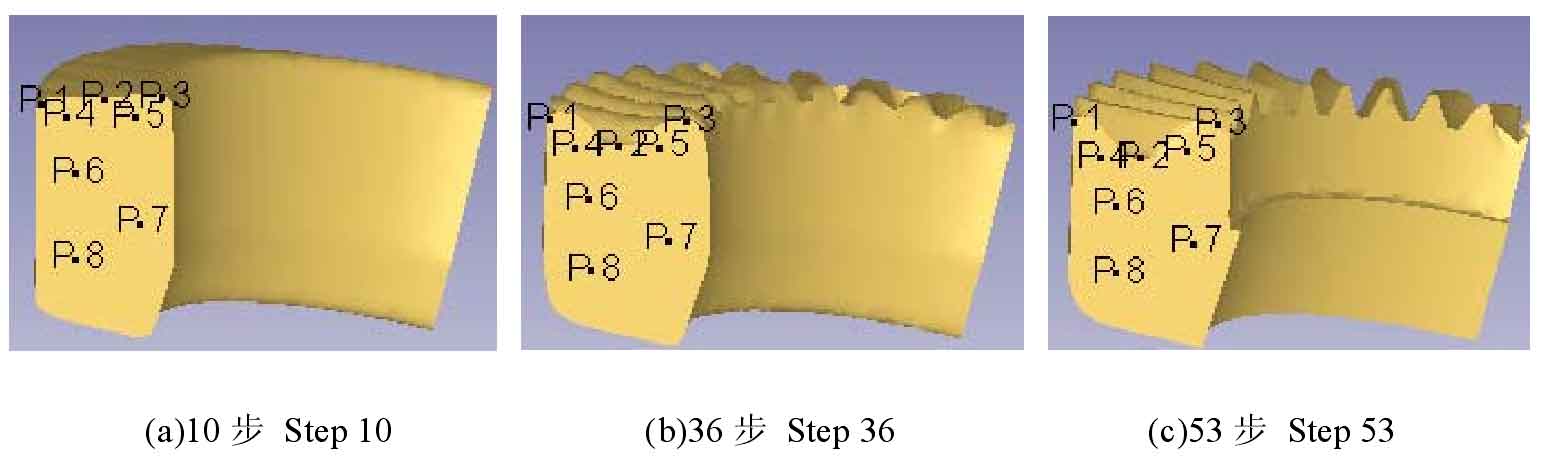

In order to facilitate the analysis, a quarter of the spiral bevel gear is selected as the research object. As shown in Fig. 4-11 (a), (b) and (c), eight different position points are drawn at different parts on the side of the forging before simulation. At the same time, three main stages in the forming process of spiral bevel gear are selected for analysis and comparison. So as to analyze the law of metal flow.

Initial stage: only the outer surface of the upper end of the forging is in contact with the tooth top of the tooth die. Under the pressing action of the tooth top of the tooth die, the metal mainly flows downward (the metal at points 1, 2, 3, 4 and 5 moves downward, and there is little change at points 6, 7 and 8). At this time, the forging is mainly upsetting deformation. With the continuous increase of the contact area between the tooth die and the upper surface of the forging, the size in the height direction decreases and the radial size increases gradually, The contact range between the forging and the gear die gradually extends from the big end to the small end.

Filling stage: when the reduction reaches a certain value, the distance between the boss of the upper die and the boss of the female die decreases gradually. After the flow of metal in the height direction is limited, it turns to the longitudinal flow to fill the tooth shape of the spiral bevel gear. This stage is mainly dominated by extrusion deformation. As shown in the figure, the movement of each point is: 2 points are at the tooth root of the forging, the movement displacement is the largest, and 1 and 3 points are at the tooth top, 4. Point 5 is at the root of the tooth. The movement displacement is small.

Completion stage: from the beginning of tooth filling, the tooth die contacts with the blank to the end of forming. In this stage, the metal mainly flows to a small amount of unfilled area. According to the simulation results, it can be observed that points 2, 4 and 5 are almost on the same line, point 7 moves towards the center of the spiral bevel gear, and points 6 and 8 only change slightly in height.